h16tp(x - AJ Maskin AS

h16tp(x - AJ Maskin AS

h16tp(x - AJ Maskin AS

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

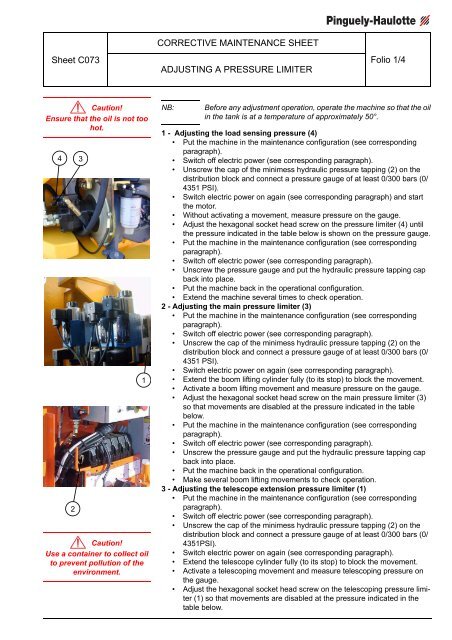

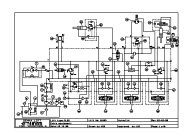

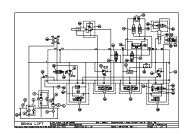

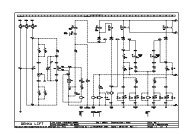

Sheet C073CORRECTIVE MAINTENANCE SHEETADJUSTING A PRESSURE LIMITERFolio 1/4Caution!Ensure that the oil is not toohot.4 32Caution!Use a container to collect oilto prevent pollution of theenvironment.1NB:Before any adjustment operation, operate the machine so that the oilin the tank is at a temperature of approximately 50°.1 - Adjusting the load sensing pressure (4)• Put the machine in the maintenance configuration (see correspondingparagraph).• Switch off electric power (see corresponding paragraph).• Unscrew the cap of the minimess hydraulic pressure tapping (2) on thedistribution block and connect a pressure gauge of at least 0/300 bars (0/4351 PSI).• Switch electric power on again (see corresponding paragraph) and startthe motor.• Without activating a movement, measure pressure on the gauge.• Adjust the hexagonal socket head screw on the pressure limiter (4) untilthe pressure indicated in the table below is shown on the pressure gauge.• Put the machine in the maintenance configuration (see correspondingparagraph).• Switch off electric power (see corresponding paragraph).• Unscrew the pressure gauge and put the hydraulic pressure tapping capback into place.• Put the machine back in the operational configuration.• Extend the machine several times to check operation.2 - Adjusting the main pressure limiter (3)• Put the machine in the maintenance configuration (see correspondingparagraph).• Switch off electric power (see corresponding paragraph).• Unscrew the cap of the minimess hydraulic pressure tapping (2) on thedistribution block and connect a pressure gauge of at least 0/300 bars (0/4351 PSI).• Switch electric power on again (see corresponding paragraph).• Extend the boom lifting cylinder fully (to its stop) to block the movement.• Activate a boom lifting movement and measure pressure on the gauge.• Adjust the hexagonal socket head screw on the main pressure limiter (3)so that movements are disabled at the pressure indicated in the tablebelow.• Put the machine in the maintenance configuration (see correspondingparagraph).• Switch off electric power (see corresponding paragraph).• Unscrew the pressure gauge and put the hydraulic pressure tapping capback into place.• Put the machine back in the operational configuration.• Make several boom lifting movements to check operation.3 - Adjusting the telescope extension pressure limiter (1)• Put the machine in the maintenance configuration (see correspondingparagraph).• Switch off electric power (see corresponding paragraph).• Unscrew the cap of the minimess hydraulic pressure tapping (2) on thedistribution block and connect a pressure gauge of at least 0/300 bars (0/4351PSI).• Switch electric power on again (see corresponding paragraph).• Extend the telescope cylinder fully (to its stop) to block the movement.• Activate a telescoping movement and measure telescoping pressure onthe gauge.• Adjust the hexagonal socket head screw on the telescoping pressure limiter(1) so that movements are disabled at the pressure indicated in thetable below.