You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

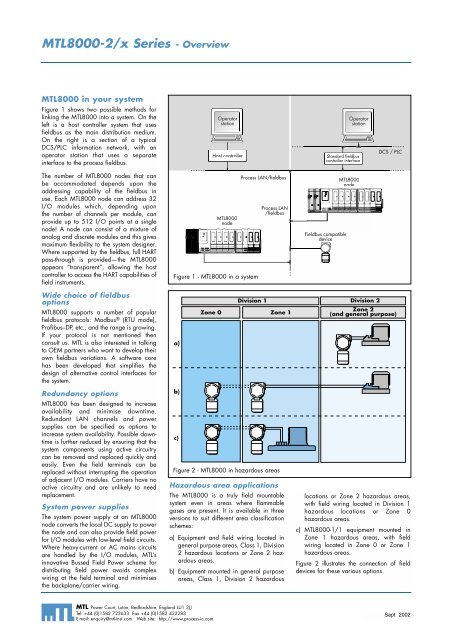

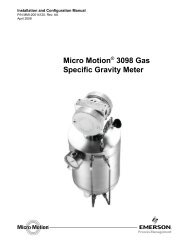

MTL<strong>8000</strong>-2/x Series - OverviewMTL<strong>8000</strong> in your systemFigure 1 shows two possible methods forlinking the MTL<strong>8000</strong> into a system. On theleft is a host controller system that usesfieldbus as the main distribution medium.On the right is a section of a typicalDCS/PLC information network, with anoperator station that uses a separateinterface to the process fieldbus.Host controllerStandard fieldbuscontroller interfaceDCS / PLCThe number of MTL<strong>8000</strong> nodes that canbe accommodated depends upon theaddressing capability of the fieldbus inuse. Each MTL<strong>8000</strong> node can address 32I/O modules which, depending uponthe number of channels per module, canprovide up to 512 I/O points at a singlenode! A node can consist of a mixture ofanalog and discrete modules and this givesmaximum flexibility to the system designer.Where supported by the fieldbus, full HARTpass-through is provided—the MTL<strong>8000</strong>appears “transparent”, allowing the hostcontroller to access the HART capabilities offield instruments.MTL<strong>8000</strong>Figure 1 - MTL<strong>8000</strong> in a systemProcess LAN/fieldbusProcess LAN/fieldbusFieldbus compatibledeviceMTL<strong>8000</strong>nodeWide choice of fieldbusoptionsMTL<strong>8000</strong> supports a number of popularfieldbus protocols: Modbus ® (RTU mode),Profibus–DP, etc., and the range is growing.If your protocol is not mentioned thenconsult us. MTL is also interested in talkingto OEM partners who want to develop theirown fieldbus variations. A software corehas been developed that simplifies thedesign of alternative control interfaces forthe system.Redundancy optionsMTL<strong>8000</strong> has been designed to increaseavailability and minimise downtime.Redundant LAN channels and powersupplies can be specified as options toincrease system availability. Possible downtimeis further reduced by ensuring that thesystem components using active circuitrycan be removed and replaced quickly andeasily. Even the field terminals can bereplaced without interrupting the operationof adjacent I/O modules. Carriers have noactive circuitry and are unlikely to needreplacement.System power suppliesThe system power supply at an MTL<strong>8000</strong>node converts the local DC supply to powerthe node and can also provide field powerfor I/O modules with low-level field circuits.Where heavy-current or AC mains circuitsare handled by the I/O modules, MTL’sinnovative Bussed Field Power scheme fordistributing field power avoids complexwiring at the field terminal and minimisesthe backplane/carrier wiring.a)b)c)Zone 0Zone 1Figure 2 - MTL<strong>8000</strong> in hazardous areasHazardous area applicationsThe MTL<strong>8000</strong> is a truly field mountablesystem even in areas where flammablegases are present. It is available in threeversions to suit different area classificationschemes:a) Equipment and field wiring located ingeneral purpose areas, Class 1, Division2 hazardous locations or Zone 2 hazardousareas.b) Equipment mounted in general purposeareas, Class 1, Division 2 hazardousDivision 1 Division 2Zone 2(and general purpose)locations or Zone 2 hazardous areas,with field wiring located in Division 1hazardous locations or Zone 0hazardous areas.c) MTL<strong>8000</strong>-1/1 equipment mounted inZone 1 hazardous areas, with fieldwiring located in Zone 0 or Zone 1hazardous areas.Figure 2 illustrates the connection of fielddevices for these various options.MTL Power Court, Luton, Bedfordshire, England LU1 3JJTel: +44 (0)1582 723633 Fax +44 (0)1582 422283E-mail: enquiry@mtl-inst.com Web site: http://www.process-io.comSept 2002