Download the file. - Groupe SEB

Download the file. - Groupe SEB

Download the file. - Groupe SEB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

R&D key figures:<br />

475 people,<br />

€46 million budget,<br />

more than 1,000 current<br />

patents.<br />

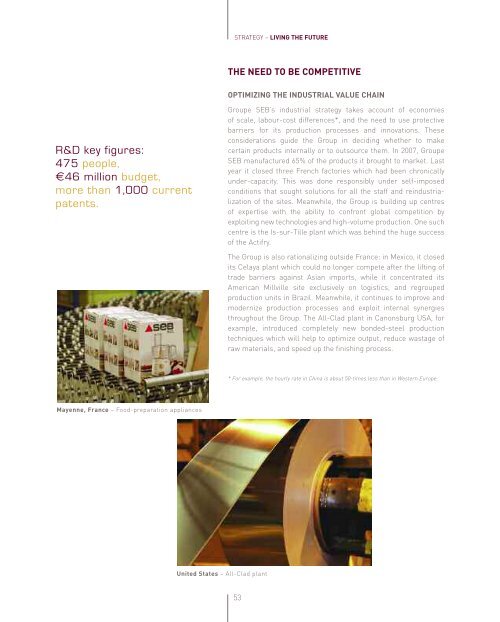

Mayenne, France – Food-preparation appliances<br />

United States – All-Clad plant<br />

STRATEGY – LIVING THE FUTURE<br />

THE NEED TO BE COMPETITIVE<br />

OPTIMIZING THE INDUSTRIAL VALUE CHAIN<br />

<strong>Groupe</strong> <strong>SEB</strong>’s industrial strategy takes account of economies<br />

of scale, labour-cost differences*, and <strong>the</strong> need to use protective<br />

barriers for its production processes and innovations. These<br />

considerations guide <strong>the</strong> Group in deciding whe<strong>the</strong>r to make<br />

certain products internally or to outsource <strong>the</strong>m. In 2007, <strong>Groupe</strong><br />

<strong>SEB</strong> manufactured 65% of <strong>the</strong> products it brought to market. Last<br />

year it closed three French factories which had been chronically<br />

under-capacity. This was done responsibly under self-imposed<br />

conditions that sought solutions for all <strong>the</strong> staff and reindustrialization<br />

of <strong>the</strong> sites. Meanwhile, <strong>the</strong> Group is building up centres<br />

of expertise with <strong>the</strong> ability to confront global competition by<br />

exploiting new technologies and high-volume production. One such<br />

centre is <strong>the</strong> Is-sur-Tille plant which was behind <strong>the</strong> huge success<br />

of <strong>the</strong> Actifry.<br />

The Group is also rationalizing outside France: in Mexico, it closed<br />

its Celaya plant which could no longer compete after <strong>the</strong> lifting of<br />

trade barriers against Asian imports, while it concentrated its<br />

American Millville site exclusively on logistics, and regrouped<br />

production units in Brazil. Meanwhile, it continues to improve and<br />

modernize production processes and exploit internal synergies<br />

throughout <strong>the</strong> Group. The All-Clad plant in Canonsburg USA, for<br />

example, introduced completely new bonded-steel production<br />

techniques which will help to optimize output, reduce wastage of<br />

raw materials, and speed up <strong>the</strong> finishing process.<br />

* For example, <strong>the</strong> hourly rate in China is about 50-times less than in Western Europe.<br />

53