CONELOG® Implant System Prosthetic Restorations - Camlog

CONELOG® Implant System Prosthetic Restorations - Camlog

CONELOG® Implant System Prosthetic Restorations - Camlog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

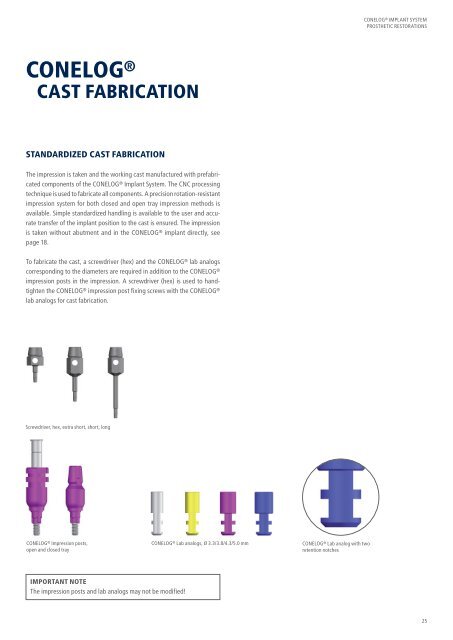

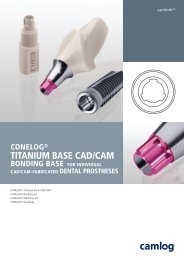

CONELOG ®<br />

CAST FABRICATION<br />

STANDARDIZED CAST FABRICATION<br />

The impression is taken and the working cast manufactured with prefabricated<br />

components of the CONELOG ® <strong>Implant</strong> <strong>System</strong>. The CNC processing<br />

technique is used to fabricate all components. A precision rotation-resistant<br />

impression system for both closed and open tray impression methods is<br />

available. Simple standardized handling is available to the user and accurate<br />

transfer of the implant position to the cast is ensured. The impression<br />

is taken without abutment and in the CONELOG ® implant directly, see<br />

page 18.<br />

To fabricate the cast, a screwdriver (hex) and the CONELOG ® lab analogs<br />

corresponding to the diameters are required in addition to the CONELOG ®<br />

impression posts in the impression. A screwdriver (hex) is used to handtighten<br />

the CONELOG ® impression post fixing screws with the CONELOG ®<br />

lab analogs for cast fabrication.<br />

Screwdriver, hex, extra short, short, long<br />

CONELOG ® Impression posts,<br />

open and closed tray<br />

IMPORTANT NOTE<br />

The impression posts and lab analogs may not be modified!<br />

CONELOG ® Lab analogs, Ø 3.3/3.8/4.3/5.0 mm<br />

CONELOG ® Lab analog with two<br />

retention notches<br />

CONELOG ® IMPLANT SYSTEM<br />

PROSTHETIC RESTORATIONS<br />

25