CONELOG® Implant System Prosthetic Restorations - Camlog

CONELOG® Implant System Prosthetic Restorations - Camlog

CONELOG® Implant System Prosthetic Restorations - Camlog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PROCESSING THE CONELOG ® ABUTMENTS<br />

EXAMPLE CONELOG ® UNIVERSAL ABUTMENTS<br />

After fabricating the cast, the CONELOG ® universal abutments are inserted<br />

into the CONELOG ® lab analogs and fixed with the CONELOG ® lab screw.<br />

A previously prepared silicone index is used to mark the height and axis<br />

alignments.<br />

The height of the abutments is first adjusted. The height of the circular functional<br />

surface must not fall below 5 mm, otherwise sufficient retention<br />

strength of the construction cannot be achieved. The uniform insertion<br />

direction is then determined and the abutments are machined with suitable<br />

abrasives in the parallelometer. The specified speeds of each abrasive used<br />

for titanium machining must be observed.<br />

Overheating the titanium leads to a very hard surface (alpha case layer) and<br />

should be avoided.<br />

For fabrication of double crowns using the electroplating technique, the<br />

manufacturer's specifications must be observed. The preparation for the<br />

cast fabrication of double crowns occurs similar to the cone-telescopic<br />

crown technique. To prevent the caps from rotating, the abutments are<br />

lightly ground in oval form. The surface must be homogeneous.<br />

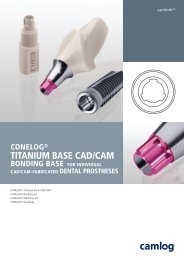

CONELOG ® IMPLANT SYSTEM<br />

PROSTHETIC RESTORATIONS<br />

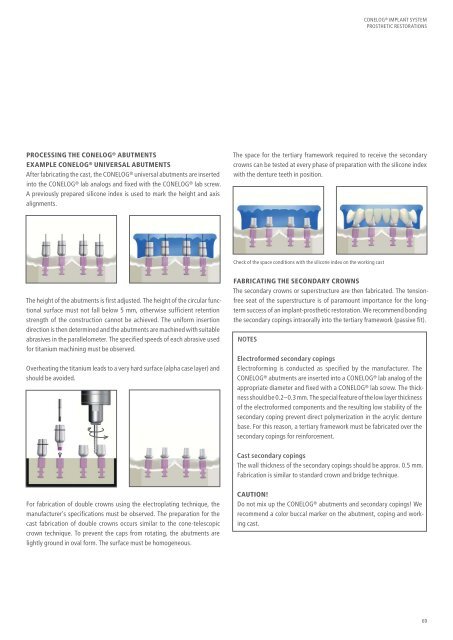

The space for the tertiary framework required to receive the secondary<br />

crowns can be tested at every phase of preparation with the silicone index<br />

with the denture teeth in position.<br />

Check of the space conditions with the silicone index on the working cast<br />

FABRICATING THE SECONDARY CROWNS<br />

The secondary crowns or superstructure are then fabricated. The tensionfree<br />

seat of the superstructure is of paramount importance for the longterm<br />

success of an implant-prosthetic restoration. We recommend bonding<br />

the secondary copings intraorally into the tertiary framework (passive fit).<br />

NOTES<br />

Electroformed secondary copings<br />

Electroforming is conducted as specified by the manufacturer. The<br />

CONELOG ® abutments are inserted into a CONELOG ® lab analog of the<br />

appropriate diameter and fixed with a CONELOG ® lab screw. The thickness<br />

should be 0.2–0.3 mm. The special feature of the low layer thickness<br />

of the electroformed components and the resulting low stability of the<br />

secondary coping prevent direct polymerization in the acrylic denture<br />

base. For this reason, a tertiary framework must be fabricated over the<br />

secondary copings for reinforcement.<br />

Cast secondary copings<br />

The wall thickness of the secondary copings should be approx. 0.5 mm.<br />

Fabrication is similar to standard crown and bridge technique.<br />

CAUTION!<br />

Do not mix up the CONELOG ® abutments and secondary copings! We<br />

recommend a color buccal marker on the abutment, coping and working<br />

cast.<br />

69