Start-Up, Operation, and Maintenance Instructions

Start-Up, Operation, and Maintenance Instructions

Start-Up, Operation, and Maintenance Instructions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

OPTIONAL<br />

METER<br />

PACKAGE<br />

INTEGRATED<br />

STARTER<br />

MODULE<br />

(ISM)<br />

OIL PUMP<br />

DISCONNECT<br />

CONTROL<br />

AND OIL<br />

HEATER<br />

DISCONNECT<br />

COMPRESSOR<br />

MOTOR<br />

DISCONNECT<br />

General — The 19XR hermetic centrifugal liquid chiller<br />

contains a microprocessor-based control center that monitors<br />

<strong>and</strong> controls all operations of the chiller (see Fig. 9). The<br />

microprocessor control system matches the cooling capacity of<br />

the chiller to the cooling load while providing state-of-the-art<br />

chiller protection. The system controls cooling load within the<br />

set point plus the deadb<strong>and</strong> by sensing the leaving chilled water<br />

or brine temperature <strong>and</strong> regulating the inlet guide vane via a<br />

mechanically linked actuator motor. The guide vane is a variable<br />

flow pre-whirl assembly that controls the refrigeration effect<br />

in the cooler by regulating the amount of refrigerant vapor<br />

flow into the compressor. An increase in guide vane opening<br />

increases capacity. A decrease in guide vane opening decreases<br />

capacity. The microprocessor-based control center protects the<br />

chiller by monitoring the digital <strong>and</strong> analog inputs <strong>and</strong> executing<br />

capacity overrides or safety shutdowns, if required.<br />

AUTO Forward<br />

SPEED RUNNING MAN Reverse<br />

VOLTS REMOTE<br />

AMPS JOG PRO- RUN<br />

Hz<br />

AUTO GRAM JOB<br />

Kw<br />

FORWARD<br />

TORQUE REVERSE<br />

Password PROGRAM ENTER<br />

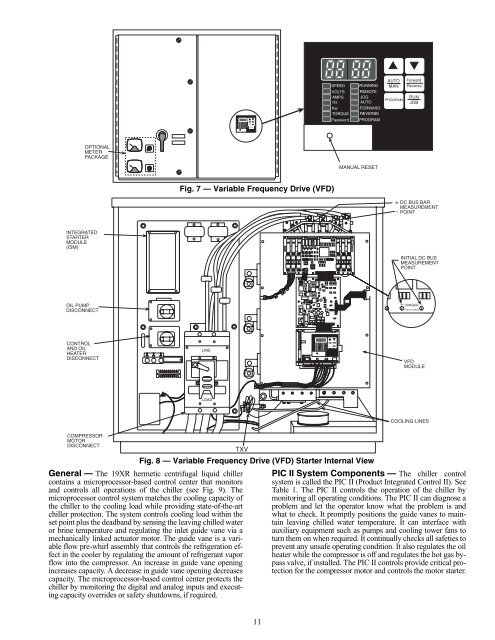

Fig. 7 — Variable Frequency Drive (VFD)<br />

LINE<br />

LOAD<br />

TXV<br />

11<br />

SPEED<br />

VOLTS<br />

AMPS<br />

Hz<br />

Kw<br />

TORQUE<br />

Password<br />

RUNNING MAN<br />

REMOTE<br />

PROGRAM<br />

JOG<br />

AUTO<br />

FORWARD<br />

REVERSE<br />

PROGRAM<br />

SPEED<br />

VOLTS<br />

AMPS<br />

Hz<br />

Kw<br />

TORQUE<br />

Password<br />

AUTO Forward<br />

Reverse<br />

RUN<br />

JOB<br />

ENTER<br />

AUTO<br />

RUNNING MAN<br />

REMOTE<br />

JOG<br />

PROGRAM<br />

AUTO<br />

FORWARD<br />

REVERSE<br />

PROGRAM<br />

MANUAL RESET<br />

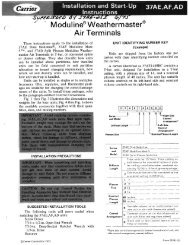

Fig. 8 — Variable Frequency Drive (VFD) <strong>Start</strong>er Internal View<br />

ENTER<br />

Forward<br />

Reverse<br />

RUN<br />

JOB<br />

DC BUS BAR<br />

MEASUREMENT<br />

POINT<br />

INITIAL DC BUS<br />

MEASUREMENT<br />

POINT<br />

+ DANGER -<br />

HIGH VOLTAGE<br />

PIC II System Components — The chiller control<br />

system is called the PIC II (Product Integrated Control II). See<br />

Table 1. The PIC II controls the operation of the chiller by<br />

monitoring all operating conditions. The PIC II can diagnose a<br />

problem <strong>and</strong> let the operator know what the problem is <strong>and</strong><br />

what to check. It promptly positions the guide vanes to maintain<br />

leaving chilled water temperature. It can interface with<br />

auxiliary equipment such as pumps <strong>and</strong> cooling tower fans to<br />

turn them on when required. It continually checks all safeties to<br />

prevent any unsafe operating condition. It also regulates the oil<br />

heater while the compressor is off <strong>and</strong> regulates the hot gas bypass<br />

valve, if installed. The PIC II controls provide critical protection<br />

for the compressor motor <strong>and</strong> controls the motor starter.<br />

+<br />

-<br />

VFD<br />

MODULE<br />

COOLING LINES