Start-Up, Operation, and Maintenance Instructions

Start-Up, Operation, and Maintenance Instructions

Start-Up, Operation, and Maintenance Instructions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

stop the chiller when a specific time period on the ice<br />

build schedule is not set for ice build.<br />

4. Entering Chilled Water Temperature <strong>and</strong> ICE BUILD<br />

Contacts — Compressor operation terminates when the<br />

ICE BUILD TERMINATION parameter is set to<br />

2 (BOTH) <strong>and</strong> the conditions described above in items<br />

2 <strong>and</strong> 3 for entering chilled water temperature <strong>and</strong> remote<br />

contacts have occurred.<br />

NOTE: It is not possible to override the CHILLER START/<br />

STOP, CONTROL POINT, <strong>and</strong> ACTIVE DEMAND LIMIT<br />

variables from CCN devices (with a priority 4 or greater) during<br />

the ice build period. However, a CCN device can override<br />

these settings during 2-chiller lead/lag operation.<br />

RETURN TO NON-ICE BUILD OPERATIONS — The ice<br />

build function forces the chiller to start, even if all other schedules<br />

indicate that the chiller should stop. When the ice build<br />

function terminates, the chiller returns to normal temperature<br />

control <strong>and</strong> start/stop schedule operation. The CHILLER<br />

START/STOP <strong>and</strong> CONTROL POINT return to normal operation.<br />

If the CHILLER START/STOP or CONTROL POINT has<br />

been forced (with a device of less than 4 priority) before the ice<br />

build function started, when the ice build function ends, the<br />

previous forces (of less than 4 priority) are not automatically<br />

restored.<br />

Attach to Network Device Control — The Service<br />

menu includes the ATTACH TO NETWORK DEVICE<br />

screen. From this screen, the operator can:<br />

enter the time schedule number (if changed) for<br />

OCCPC03S, as defined in the NET_OPT screen<br />

attach the CVC/ICVC to any CCN device, if the chiller<br />

has been connected to a CCN network. This may include<br />

other PIC-controlled chillers.<br />

upgrade software<br />

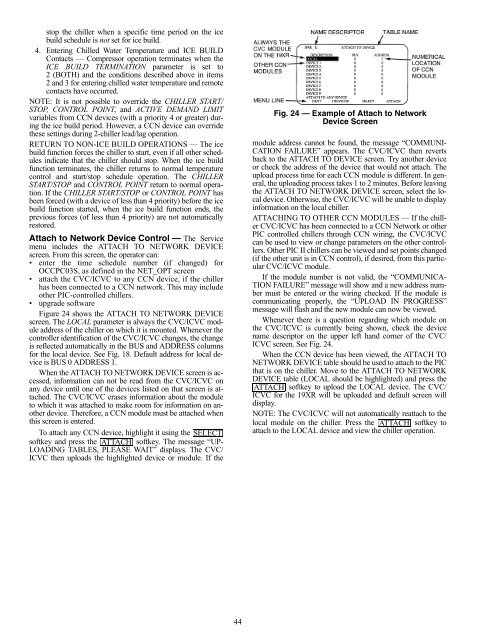

Figure 24 shows the ATTACH TO NETWORK DEVICE<br />

screen. The LOCAL parameter is always the CVC/ICVC module<br />

address of the chiller on which it is mounted. Whenever the<br />

controller identification of the CVC/ICVC changes, the change<br />

is reflected automatically in the BUS <strong>and</strong> ADDRESS columns<br />

for the local device. See Fig. 18. Default address for local device<br />

is BUS 0 ADDRESS 1.<br />

When the ATTACH TO NETWORK DEVICE screen is accessed,<br />

information can not be read from the CVC/ICVC on<br />

any device until one of the devices listed on that screen is attached.<br />

The CVC/ICVC erases information about the module<br />

to which it was attached to make room for information on another<br />

device. Therefore, a CCN module must be attached when<br />

this screen is entered.<br />

To attach any CCN device, highlight it using the SELECT<br />

softkey <strong>and</strong> press the ATTACH softkey. The message “UP-<br />

LOADING TABLES, PLEASE WAIT” displays. The CVC/<br />

ICVC then uploads the highlighted device or module. If the<br />

44<br />

module address cannot be found, the message “COMMUNI-<br />

CATION FAILURE” appears. The CVC/ICVC then reverts<br />

back to the ATTACH TO DEVICE screen. Try another device<br />

or check the address of the device that would not attach. The<br />

upload process time for each CCN module is different. In general,<br />

the uploading process takes 1 to 2 minutes. Before leaving<br />

the ATTACH TO NETWORK DEVICE screen, select the local<br />

device. Otherwise, the CVC/ICVC will be unable to display<br />

information on the local chiller.<br />

ATTACHING TO OTHER CCN MODULES — If the chiller<br />

CVC/ICVC has been connected to a CCN Network or other<br />

PIC controlled chillers through CCN wiring, the CVC/ICVC<br />

can be used to view or change parameters on the other controllers.<br />

Other PIC II chillers can be viewed <strong>and</strong> set points changed<br />

(if the other unit is in CCN control), if desired, from this particular<br />

CVC/ICVC module.<br />

If the module number is not valid, the “COMMUNICA-<br />

TION FAILURE” message will show <strong>and</strong> a new address number<br />

must be entered or the wiring checked. If the module is<br />

communicating properly, the “UPLOAD IN PROGRESS”<br />

message will flash <strong>and</strong> the new module can now be viewed.<br />

Whenever there is a question regarding which module on<br />

the CVC/ICVC is currently being shown, check the device<br />

name descriptor on the upper left h<strong>and</strong> corner of the CVC/<br />

ICVC screen. See Fig. 24.<br />

When the CCN device has been viewed, the ATTACH TO<br />

NETWORK DEVICE table should be used to attach to the PIC<br />

that is on the chiller. Move to the ATTACH TO NETWORK<br />

DEVICE table (LOCAL should be highlighted) <strong>and</strong> press the<br />

ATTACH<br />

Fig. 24 — Example of Attach to Network<br />

Device Screen<br />

softkey to upload the LOCAL device. The CVC/<br />

ICVC for the 19XR will be uploaded <strong>and</strong> default screen will<br />

display.<br />

NOTE: The CVC/ICVC will not automatically reattach to the<br />

local module on the chiller. Press the ATTACH softkey to<br />

attach to the LOCAL device <strong>and</strong> view the chiller operation.