User's Manual TNC 360 (from 259 900-11) - heidenhain

User's Manual TNC 360 (from 259 900-11) - heidenhain

User's Manual TNC 360 (from 259 900-11) - heidenhain

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7 Programming with Q Parameters<br />

7.1 Q Parameters Instead of Numerical Values<br />

7-4<br />

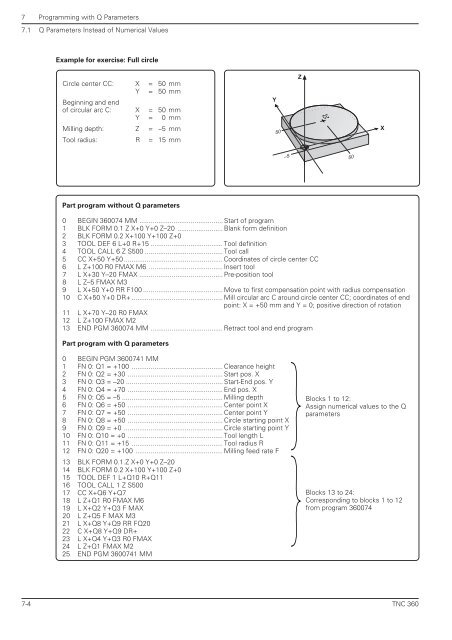

Example for exercise: Full circle<br />

Circle center CC: X = 50 mm<br />

Beginning and end<br />

Y = 50 mm<br />

of circular arc C: X = 50 mm<br />

Y = 0 mm<br />

Milling depth: Z = –5 mm<br />

Tool radius: R = 15 mm<br />

Part program without Q parameters<br />

0 BEGIN <strong>360</strong>074 MM ............................................ Start of program<br />

1 BLK FORM 0.1 Z X+0 Y+0 Z–20 ........................ Blank form definition<br />

2 BLK FORM 0.2 X+100 Y+100 Z+0<br />

3 TOOL DEF 6 L+0 R+15 ...................................... Tool definition<br />

4 TOOL CALL 6 Z S500 ......................................... Tool call<br />

5 CC X+50 Y+50 .................................................... Coordinates of circle center CC<br />

6 L Z+100 R0 FMAX M6 ....................................... Insert tool<br />

7 L X+30 Y–20 FMAX ............................................ Pre-position tool<br />

8 L Z–5 FMAX M3<br />

9 L X+50 Y+0 RR F100 .......................................... Move to first compensation point with radius compensation<br />

10 C X+50 Y+0 DR+ ................................................ Mill circular arc C around circle center CC; coordinates of end<br />

point: X = +50 mm and Y = 0; positive direction of rotation<br />

<strong>11</strong> L X+70 Y–20 R0 FMAX<br />

12 L Z+100 FMAX M2<br />

13 END PGM <strong>360</strong>074 MM ...................................... Retract tool and end program<br />

Part program with Q parameters<br />

0 BEGIN PGM <strong>360</strong>0741 MM<br />

1 FN 0: Q1 = +100 ................................................ Clearance height<br />

2 FN 0: Q2 = +30 .................................................. Start pos. X<br />

3 FN 0: Q3 = –20 ................................................... Start-End pos. Y<br />

4 FN 0: Q4 = +70 .................................................. End pos. X<br />

5 FN 0: Q5 = –5 ..................................................... Milling depth<br />

6 FN 0: Q6 = +50 .................................................. Center point X<br />

7 FN 0: Q7 = +50 .................................................. Center point Y<br />

8 FN 0: Q8 = +50 .................................................. Circle starting point X<br />

9 FN 0: Q9 = +0 .................................................... Circle starting point Y<br />

10 FN 0: Q10 = +0 .................................................. Tool length L<br />

<strong>11</strong> FN 0: Q<strong>11</strong> = +15 ................................................ Tool radius R<br />

12 FN 0: Q20 = +100 .............................................. Milling feed rate F<br />

13 BLK FORM 0.1.Z X+0 Y+0 Z–20<br />

14 BLK FORM 0.2 X+100 Y+100 Z+0<br />

15 TOOL DEF 1 L+Q10 R+Q<strong>11</strong><br />

16 TOOL CALL 1 Z S500<br />

17 CC X+Q6 Y+Q7<br />

18 L Z+Q1 R0 FMAX M6<br />

19 L X+Q2 Y+Q3 F MAX<br />

20 L Z+Q5 F MAX M3<br />

21 L X+Q8 Y+Q9 RR FQ20<br />

22 C X+Q8 Y+Q9 DR+<br />

23 L X+Q4 Y+Q3 R0 FMAX<br />

24 L Z+Q1 FMAX M2<br />

25 END PGM <strong>360</strong>0741 MM<br />

Y<br />

50<br />

–5<br />

Z<br />

CC<br />

50<br />

Blocks 1 to 12:<br />

Assign numerical values to the Q<br />

parameters<br />

Blocks 13 to 24:<br />

Corresponding to blocks 1 to 12<br />

<strong>from</strong> program <strong>360</strong>074<br />

X<br />

<strong>TNC</strong> <strong>360</strong>