User's Manual TNC 360 (from 259 900-11) - heidenhain

User's Manual TNC 360 (from 259 900-11) - heidenhain

User's Manual TNC 360 (from 259 900-11) - heidenhain

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8 Cycles<br />

8.3 SL Cycles<br />

<strong>TNC</strong> <strong>360</strong><br />

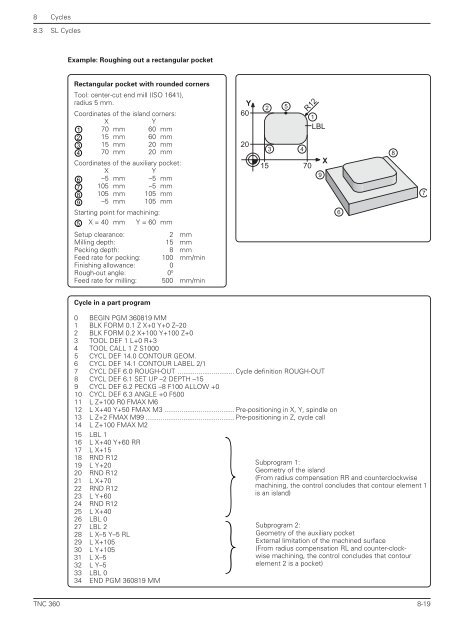

Example: Roughing out a rectangular pocket<br />

Rectangular pocket with rounded corners<br />

Tool: center-cut end mill (ISO 1641),<br />

radius 5 mm.<br />

Coordinates of the island corners:<br />

X Y<br />

1 70 mm 60 mm<br />

2 15 mm 60 mm<br />

3 15 mm 20 mm<br />

4 70 mm 20 mm<br />

Coordinates of the auxiliary pocket:<br />

X Y<br />

6 –5 mm –5 mm<br />

7 105 mm –5 mm<br />

8 105 mm 105 mm<br />

9 –5 mm 105 mm<br />

Starting point for machining:<br />

5 X = 40 mm Y = 60 mm<br />

Setup clearance: 2 mm<br />

Milling depth: 15 mm<br />

Pecking depth: 8 mm<br />

Feed rate for pecking: 100 mm/min<br />

Finishing allowance: 0<br />

Rough-out angle: 00 Feed rate for milling: 500 mm/min<br />

Cycle in a part program<br />

Y<br />

60<br />

20<br />

2<br />

5<br />

3 4<br />

15 70<br />

R12<br />

1<br />

LBL<br />

0 BEGIN PGM <strong>360</strong>819 MM<br />

1 BLK FORM 0.1 Z X+0 Y+0 Z–20<br />

2 BLK FORM 0.2 X+100 Y+100 Z+0<br />

3 TOOL DEF 1 L+0 R+3<br />

4 TOOL CALL 1 Z S1000<br />

5 CYCL DEF 14.0 CONTOUR GEOM.<br />

6 CYCL DEF 14.1 CONTOUR LABEL 2/1<br />

7 CYCL DEF 6.0 ROUGH-OUT .............................. Cycle definition ROUGH-OUT<br />

8 CYCL DEF 6.1 SET UP –2 DEPTH –15<br />

9 CYCL DEF 6.2 PECKG –8 F100 ALLOW +0<br />

10 CYCL DEF 6.3 ANGLE +0 F500<br />

<strong>11</strong> L Z+100 R0 FMAX M6<br />

12 L X+40 Y+50 FMAX M3 ..................................... Pre-positioning in X, Y, spindle on<br />

13 L Z+2 FMAX M99 ............................................... Pre-positioning in Z, cycle call<br />

14 L Z+100 FMAX M2<br />

15 LBL 1<br />

16 L X+40 Y+60 RR<br />

17 L X+15<br />

18 RND R12<br />

19 L Y+20<br />

20 RND R12<br />

21 L X+70<br />

22 RND R12<br />

23 L Y+60<br />

24 RND R12<br />

25 L X+40<br />

26 LBL 0<br />

27 LBL 2<br />

28 L X–5 Y–5 RL<br />

29 L X+105<br />

30 L Y+105<br />

31 L X–5<br />

32 L Y–5<br />

33 LBL 0<br />

34 END PGM <strong>360</strong>819 MM<br />

9<br />

X<br />

6<br />

Subprogram 1:<br />

Geometry of the island<br />

(From radius compensation RR and counterclockwise<br />

machining, the control concludes that contour element 1<br />

is an island)<br />

Subprogram 2:<br />

Geometry of the auxiliary pocket<br />

External limitation of the machined surface<br />

(From radius compensation RL and counter-clockwise<br />

machining, the control concludes that contour<br />

element 2 is a pocket)<br />

8<br />

7<br />

8-19