User's Manual TNC 360 (from 259 900-11) - heidenhain

User's Manual TNC 360 (from 259 900-11) - heidenhain

User's Manual TNC 360 (from 259 900-11) - heidenhain

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8 Cycles<br />

8.2 Simple Fixed Cycles<br />

POCKET MILLING (Cycle 4)<br />

8-12<br />

Process<br />

The rectangular pocket milling cycle is a roughing cycle, in which<br />

• the tool penetrates the workpiece at the starting position (pocket<br />

center)<br />

• the tool subsequently follows the programmed path at the specified<br />

feed rate (see Fig. 8.9) .<br />

The cutter begins milling in the positive axis direction of the longer side.<br />

With square pockets, the cutter begins in the positive Y-direction. At the<br />

end of the cycle, the tool returns to the starting position.<br />

Requirements / Limitations<br />

This cycle requires a center-cut end mill (ISO 1641) or a separate pilot<br />

drilling operation at the pocket center. The pocket sides are parallel to the<br />

axes of the coordinate system.<br />

Input data<br />

• Setup clearance A<br />

• Milling depth B<br />

• Pecking depth C<br />

• FEED RATE FOR PECKING:<br />

Traversing speed of the tool during penetration.<br />

• FIRST SIDE LENGTH D :<br />

Length of the pocket, parallel to the first main axis of the working<br />

plane.<br />

• SECOND SIDE LENGTH E :<br />

Width of the pocket<br />

The signs of the side lengths are always positive<br />

• FEED RATE:<br />

Traversing speed of the tool in the working plane.<br />

• DIRECTION OF THE MILLING PATH:<br />

DR + : Climb milling with M3<br />

DR – : Up-cut milling with M3<br />

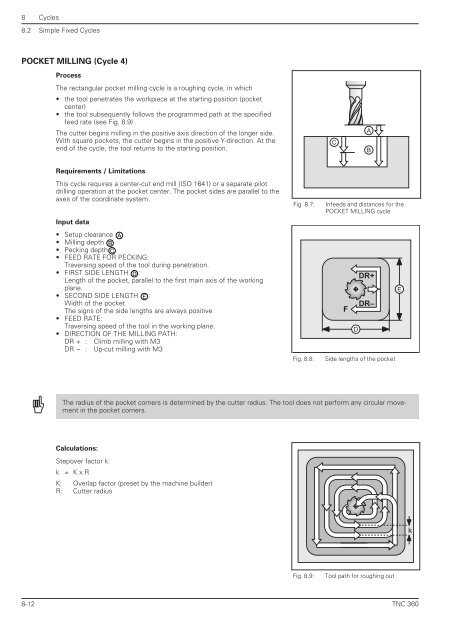

Fig. 8.7: Infeeds and distances for the<br />

POCKET MILLING cycle<br />

Fig. 8.8: Side lengths of the pocket<br />

The radius of the pocket corners is determined by the cutter radius. The tool does not perform any circular movement<br />

in the pocket corners.<br />

Calculations:<br />

Stepover factor k:<br />

k = K x R<br />

K: Overlap factor (preset by the machine builder)<br />

R: Cutter radius<br />

C<br />

F<br />

Fig. 8.9: Tool path for roughing out<br />

D<br />

A<br />

B<br />

DR+<br />

DR–<br />

E<br />

k<br />

<strong>TNC</strong> <strong>360</strong>