User's Manual TNC 360 (from 259 900-11) - heidenhain

User's Manual TNC 360 (from 259 900-11) - heidenhain

User's Manual TNC 360 (from 259 900-11) - heidenhain

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8 Cycles<br />

8.2 Simple Fixed Cycles<br />

TAPPING with floating tap holder (cycle 2)<br />

<strong>TNC</strong> <strong>360</strong><br />

Process<br />

• The thread is cut in one pass.<br />

• When the tool reaches the total hole depth, the<br />

direction of spindle rotation is reversed. After the<br />

programmed dwell time the tool is retracted to<br />

the starting position.<br />

• At the starting position, the direction of rotation<br />

is reversed once again.<br />

Required tool<br />

A floating tap holder is required for tapping. The<br />

floating tap holder compensates the tolerances for<br />

feed rate and spindle speed during the tapping<br />

process.<br />

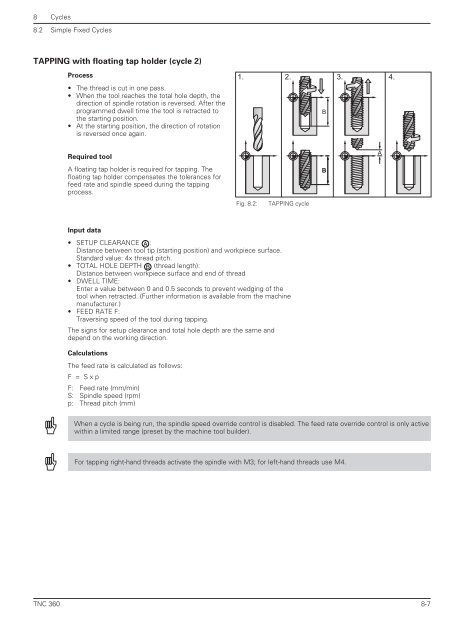

1. 2. 3. 4.<br />

Fig. 8.2: TAPPING cycle<br />

Input data<br />

• SETUP CLEARANCE A :<br />

Distance between tool tip (starting position) and workpiece surface.<br />

Standard value: 4x thread pitch.<br />

• TOTAL HOLE DEPTH B (thread length):<br />

Distance between workpiece surface and end of thread<br />

• DWELL TIME:<br />

Enter a value between 0 and 0.5 seconds to prevent wedging of the<br />

tool when retracted. (Further information is available <strong>from</strong> the machine<br />

manufacturer.)<br />

• FEED RATE F:<br />

Traversing speed of the tool during tapping.<br />

The signs for setup clearance and total hole depth are the same and<br />

depend on the working direction.<br />

Calculations<br />

The feed rate is calculated as follows:<br />

F = S x p<br />

F: Feed rate (mm/min)<br />

S: Spindle speed (rpm)<br />

p: Thread pitch (mm)<br />

When a cycle is being run, the spindle speed override control is disabled. The feed rate override control is only active<br />

within a limited range (preset by the machine tool builder).<br />

For tapping right-hand threads activate the spindle with M3; for left-hand threads use M4.<br />

B<br />

B<br />

A<br />

8-7