- Page 1 and 2: INSTRUMENTATION CATALOG 2 0 0 0 - 2

- Page 3 and 4: B1 FABGUARDTM Sensor Integration an

- Page 5 and 6: FabGuard TM Sensor Integration and

- Page 7 and 8: Residual Gas and Process Gas Analyz

- Page 9 and 10: Applications and Accessories Residu

- Page 11 and 12: Transpector® 2 Gas Analysis System

- Page 13 and 14: Transpector® 2 Gas Analysis System

- Page 15 and 16: Transpector® 2 Gas Analysis System

- Page 17 and 18: TranspectorWare TM Software Residua

- Page 19 and 20: Transpector® 2 Gas Analysis System

- Page 21 and 22: Transpector® XPR Gas Analysis Syst

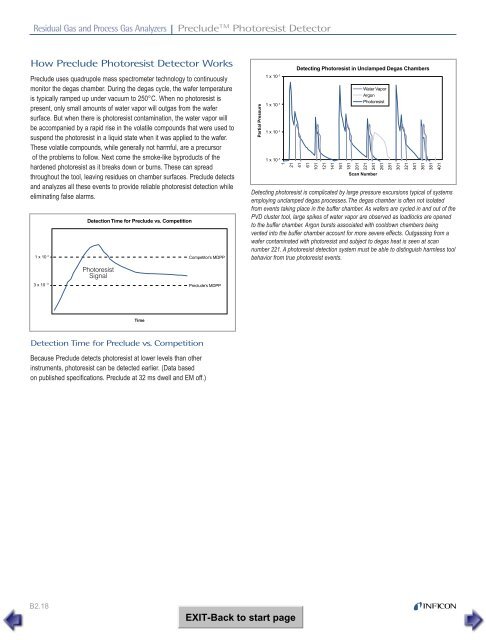

- Page 23: Preclude TM Photoresist Detector Re

- Page 27 and 28: Transpector® CIS2 Gas Analysis Sys

- Page 29 and 30: Transpector® CIS2 Gas Analysis Sys

- Page 31 and 32: Transpector® CIS2 Gas Analysis Sys

- Page 33 and 34: PPM 422 Plasma Process Monitor Resi

- Page 35 and 36: Composer® Gas Composition Controll

- Page 37 and 38: TWare32 TM for Windows ® 95/98/NT/

- Page 39 and 40: TWare32 TM for Windows® 95/98/NT/2

- Page 41 and 42: TWare32 TM for Windows ® 95/98/NT/

- Page 43 and 44: IPC400 Pumping Packages Residual Ga

- Page 45 and 46: B3 Thin Film Metrology Sensor Syste

- Page 47 and 48: LES1200 Thin Film Metrology Sensor

- Page 49 and 50: LES1200 Thin Film Metrology Sensor

- Page 51 and 52: OES1200 Optical Emission Sensor Thi

- Page 53 and 54: OES1200 Optical Emission Sensor Thi

- Page 55 and 56: Thin Film Deposition Controllers an

- Page 57 and 58: Thin Film Deposition Controllers an

- Page 59 and 60: Thin Film Deposition Controllers an

- Page 61 and 62: Thin Film Deposition Controllers an

- Page 63 and 64: Thin Film Deposition Controllers an

- Page 65 and 66: Thin Film Deposition Controllers an

- Page 67 and 68: Thin Film Deposition Controllers an

- Page 69 and 70: Thin Film Deposition Controllers an

- Page 71 and 72: Thin Film Deposition Controllers an

- Page 73 and 74: Thin Film Deposition Controllers an

- Page 75 and 76:

Thin Film Deposition Controllers an

- Page 77 and 78:

Thin Film Deposition Controllers an

- Page 79 and 80:

Leak Detectors Contents General App

- Page 81 and 82:

Leak Detectors Leak Detection - Lea

- Page 83 and 84:

Leak Detectors Leak Detection Metho

- Page 85 and 86:

Leak Detectors Operating Principles

- Page 87 and 88:

Leak Detectors ULTRATEST UL 200 Hel

- Page 89 and 90:

Leak Detectors Modul 200 Mobile and

- Page 91 and 92:

Leak Detectors Mobile Leak Detectio

- Page 93 and 94:

Leak Detectors LDS 1000 Modular Lea

- Page 95 and 96:

Leak Detectors ULTRATEST UL 500 Sta

- Page 97 and 98:

Leak Detectors ULTRATEST UL 500 dry

- Page 99 and 100:

Leak Detectors Protec Helium Sniffe

- Page 101 and 102:

Leak Detectors Ecotec II Sniffer Le

- Page 103 and 104:

Leak Detectors HLD4000A Sniffer Lea

- Page 105 and 106:

Leak Detectors Contura Z Helium Lea

- Page 107 and 108:

Leak Detectors Calibrated Leaks Cal

- Page 109 and 110:

Leak Detectors Screw-in Calibrated

- Page 111 and 112:

Leak Detectors Helium Sample Probes

- Page 113 and 114:

Leak Detectors Accessories for UL 2

- Page 115 and 116:

Leak Detectors Connection Flanges a

- Page 117 and 118:

Vacuum Gauges Contents General Basi

- Page 119 and 120:

Vacuum Gauges Transmitter Technolog

- Page 121 and 122:

Vacuum Gauges SKY TM Capacitance Di

- Page 123 and 124:

Vacuum Gauges SKY TM Capacitance Di

- Page 125 and 126:

Vacuum Gauges SKY TM Capacitance Di

- Page 127 and 128:

Vacuum Gauges Bayard-Alpert Pirani

- Page 129 and 130:

Vacuum Gauges Bayard-Alpert Pirani

- Page 131 and 132:

Vacuum Gauges Pirani Standard Gauge

- Page 133 and 134:

Vacuum Gauges Pirani Standard Gauge

- Page 135 and 136:

Vacuum Gauges Bayard-Alpert Gauge F

- Page 137 and 138:

Vacuum Gauges Penning Gauge PEG100

- Page 139 and 140:

Vacuum Gauges Vacuum Gauge Controll

- Page 141 and 142:

Vacuum Gauges Vacuum Gauge Controll

- Page 143 and 144:

Vacuum Gauges Calibration Service C

- Page 145 and 146:

Vacuum Feedthroughs Contents Produc

- Page 147 and 148:

Vacuum Feedthroughs Rotary Feedthro

- Page 149 and 150:

Vacuum Feedthroughs Linear Motion F

- Page 151 and 152:

Vacuum Feedthroughs Viewports ISO-K

- Page 153 and 154:

Vacuum Feedthroughs Viewports CF

- Page 155 and 156:

Vacuum Feedthroughs Electrical Feed

- Page 157 and 158:

Vacuum Feedthroughs Electrical Feed

- Page 159 and 160:

Vacuum Feedthroughs Coaxial Feedthr

- Page 161 and 162:

Vacuum Feedthroughs Liquid Feedthro

- Page 163 and 164:

Vacuum Feedthroughs Lubricants and

- Page 165 and 166:

Vacuum Valves B8

- Page 167 and 168:

Angle and Inline Valves Vacuum Valv

- Page 169 and 170:

Angle and Inline Valves Vacuum Valv

- Page 171 and 172:

Angle and Inline Valves Vacuum Valv

- Page 173 and 174:

Angle and Inline Valves Vacuum Valv

- Page 175 and 176:

Angle and Inline Valves Vacuum Valv

- Page 177 and 178:

Angle Valves Vacuum Valves Solenoid

- Page 179 and 180:

Angle Valves Vacuum Valves Type DN

- Page 181 and 182:

Butterfly Valves Vacuum Valves Conn

- Page 183 and 184:

Butterfly Valves Vacuum Valves VBP1

- Page 185 and 186:

Gas Dosing Valves Vacuum Valves Gas

- Page 187 and 188:

Gas Dosing Valves Vacuum Valves Man

- Page 189 and 190:

Control Valves Vacuum Valves Contro

- Page 191 and 192:

Controllers Vacuum Valves Controlle

- Page 193 and 194:

Venting Valves Vacuum Valves Ventin

- Page 195 and 196:

Safety Valves Vacuum Valves Safety

- Page 197 and 198:

Vacuum Locks and Sealing Valves Vac

- Page 199 and 200:

Vacuum Fittings Fittings and Ultra-

- Page 201 and 202:

General Vacuum Fittings Seals Seal

- Page 203 and 204:

ISO-KF Small Flange Components Vacu

- Page 205 and 206:

ISO-KF Small Flange Components Vacu

- Page 207 and 208:

ISO-KF Small Flange Components Vacu

- Page 209 and 210:

ISO-KF Small Flange Components Vacu

- Page 211 and 212:

ISO-KF Small Flange Components Vacu

- Page 213 and 214:

ISO-KF Small Flange Components Vacu

- Page 215 and 216:

ISO-K Clamp Flange Components Vacuu

- Page 217 and 218:

ISO-K Clamp Flange Components Vacuu

- Page 219 and 220:

ISO-K Clamp Flange Components Vacuu

- Page 221 and 222:

ISO-K Clamp Flange Components Vacuu

- Page 223 and 224:

ISO-F Fixed Flange Components Vacuu

- Page 225 and 226:

UHV CF Components Vacuum Fittings C

- Page 227 and 228:

UHV CF Components Vacuum Fittings F

- Page 229 and 230:

UHV CF Components Vacuum Fittings F

- Page 231 and 232:

UHV CF Components Vacuum Fittings P

- Page 233 and 234:

UHV CF Components Vacuum Fittings P

- Page 235 and 236:

Oil Diffusion Pumps Contents Produc

- Page 237 and 238:

Oil Diffusion Pumps Diffusion Pumps

- Page 239 and 240:

Oil Diffusion Pumps Diffusion Pumps

- Page 241 and 242:

Oil Diffusion Pumps Pump Accessorie

- Page 243 and 244:

Oil Diffusion Pumps Baffle Baffle W

- Page 245 and 246:

Oil Diffusion Pumps Refrigerator Re

- Page 247 and 248:

Oil Diffusion Pumps LN 2 Supply Ind

- Page 249 and 250:

Oil Diffusion Pumps Pumping System

- Page 251 and 252:

Oil Diffusion Pumps Titanium Sublim

- Page 253 and 254:

Oil Diffusion Pumps Pumping Body Pu

- Page 255 and 256:

Oil Diffusion Pumps Catalyzer Trap

- Page 257 and 258:

Product Index Instrumentation Catal

- Page 259 and 260:

Product Index Instrumentation Catal

- Page 261 and 262:

Inquiry Form Instrumentation Catalo