Blackburn Wastewater Treatment Plant Upgrade Study

Blackburn Wastewater Treatment Plant Upgrade Study

Blackburn Wastewater Treatment Plant Upgrade Study

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

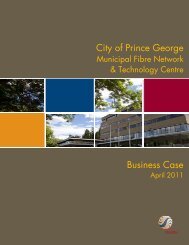

Section 4.0 - Blackbum <strong>Treatment</strong> Options<br />

Secondary <strong>Treatment</strong><br />

Secondary activated sludge processes involve aeration basin(s) and clarifiers.<br />

<strong>Wastewater</strong> enters the basins where it is aerated and mixed with a population<br />

of preconditioned microorganisms. Soluble organic material is removed from<br />

the wastewater by biological oxidation, and the insoluble material is removed<br />

by physical entrapment and adsorption within the floc. This mixture of<br />

microorganisms and organic matter is called mixed liquor suspended solids, or<br />

activated sludge. AAer leaving the aeration basin, the mixed fiquor is<br />

separated into a clear supernatant fraction (secondary effluent) and settled<br />

solids (return activated sludge). The return activated sludge is pumped back to<br />

the aeration basin and mixed with the raw influent to maintain the microbial<br />

population. The solids retentmn time (SRT) or sludge age, is controlled by<br />

daily wasting a fraction of either the mixed liquor or the return activated<br />

sludge. This serves to offset excessive microbial growth in the aeration basin.<br />

Conventional activated sludge processes are designed solely for BOD and TSS<br />

reduction; an hydraulic retention time of only 7 h, and a sludge age of 4 to 7 d<br />

are required for this. If ammonia toxicity in the effluent is an issue, the<br />

retention times must be increased to foster nitrification, which is the<br />

conversion of ammonia to nitrites and nitrates. Organisms, which perform this<br />

reaction generally, grow at a slower rate. This modification is called extended<br />

aeration, and involves doubling the hydraulic and solids retention times. A<br />

small non-aerated compartment known as an anoxic selector is usually<br />

included at the inlet to the aeration tank. This environment favours the growth<br />

of flac-forming organisms over filamentous organisms, which enhance the<br />

settleability of the mixed liquor, which in turn improves the quality of the<br />

secondary effluent. In addition, it reduces some of the nitrates produced in the<br />

nitrification reaction. Nitrates are converted to dissolved nitrogen, which<br />

evolves as nitrogen gas to the atmosphere.<br />

In the event that primary treatment is not included, the secondary treatment<br />

parameters described above would require further increase by a factor of<br />

approximately 1.5 to 2.0. A process flow diagram of the activated sludge<br />

process as it may be applied at this site is described below. Screened<br />

wastewater is combined with return activated sludge and enters an anoxic cell,<br />

which in turn discharges to an oxidation ditch equipped with fine bubble<br />

diffusers and mixers to drive the flow around the circuit. Due to the absence of<br />

primary clarifiers, the oxidation ditch will be sized for a hydraulic retention<br />

time of 24 h to ensure nitrification. The mixed liquor then flows to two<br />

secondary clarifiers, each sized for 50 percent of the total flow. Emuent from