USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

maintenance- and supply-response<br />

time, administrative delays and time<br />

for other activities that result in Not<br />

Mission Capable status<br />

spares will normally be required to be stored locally<br />

to meet availability requirements.<br />

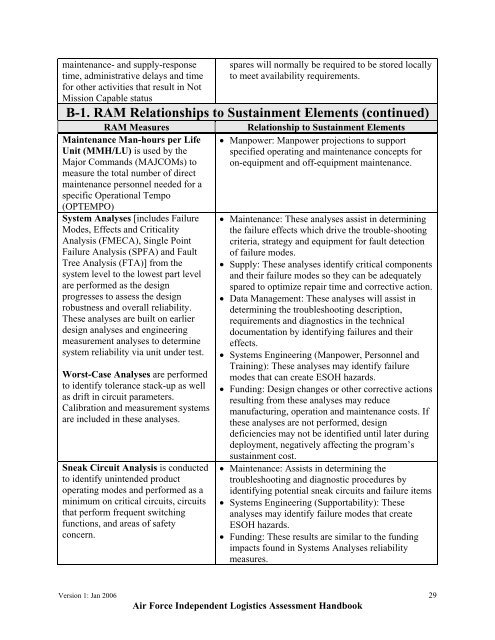

B-1. RAM Relationships to Sustainment Elements (continued)<br />

RAM Measures<br />

Maintenance Man-hours per Life<br />

Unit (MMH/LU) is used by the<br />

Major Commands (MAJCOMs) to<br />

measure the total number of direct<br />

maintenance personnel needed for a<br />

specific Operational Tempo<br />

(OPTEMPO)<br />

System Analyses [includes Failure<br />

Modes, Effects and Criticality<br />

Analysis (FMECA), Single Point<br />

Failure Analysis (SPFA) and Fault<br />

Tree Analysis (FTA)] from the<br />

system level to the lowest part level<br />

are performed as the design<br />

progresses to assess the design<br />

robustness and overall reliability.<br />

These analyses are built on earlier<br />

design analyses and engineering<br />

measurement analyses to determine<br />

system reliability via unit under test.<br />

Worst-Case Analyses are performed<br />

to identify tolerance stack-up as well<br />

as drift in circuit parameters.<br />

Calibration and measurement systems<br />

are included in these analyses.<br />

Sneak Circuit Analysis is conducted<br />

to identify unintended product<br />

operating modes and performed as a<br />

minimum on critical circuits, circuits<br />

that perform frequent switching<br />

functions, and areas of safety<br />

concern.<br />

Relationship to Sustainment Elements<br />

• Manpower: Manpower projections to support<br />

specified operating and maintenance concepts for<br />

on-equipment and off-equipment maintenance.<br />

• Maintenance: These analyses assist in determining<br />

the failure effects which drive the trouble-shooting<br />

criteria, strategy and equipment for fault detection<br />

of failure modes.<br />

• Supply: These analyses identify critical components<br />

and their failure modes so they can be adequately<br />

spared to optimize repair time and corrective action.<br />

• Data Management: These analyses will assist in<br />

determining the troubleshooting description,<br />

requirements and diagnostics in the technical<br />

documentation by identifying failures and their<br />

effects.<br />

• Systems Engineering (Manpower, Personnel and<br />

Training): These analyses may identify failure<br />

modes that can create ESOH hazards.<br />

• Funding: Design changes or other corrective actions<br />

resulting from these analyses may reduce<br />

manufacturing, operation and maintenance costs. If<br />

these analyses are not performed, design<br />

deficiencies may not be identified until later during<br />

deployment, negatively affecting the program’s<br />

sustainment cost.<br />

• Maintenance: Assists in determining the<br />

troubleshooting and diagnostic procedures by<br />

identifying potential sneak circuits and failure items<br />

• Systems Engineering (Supportability): These<br />

analyses may identify failure modes that create<br />

ESOH hazards.<br />

• Funding: These results are similar to the funding<br />

impacts found in Systems Analyses reliability<br />

measures.<br />

Version 1: Jan 2006 29<br />

Air Force Independent Logistics Assessment <strong>Handbook</strong>