USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

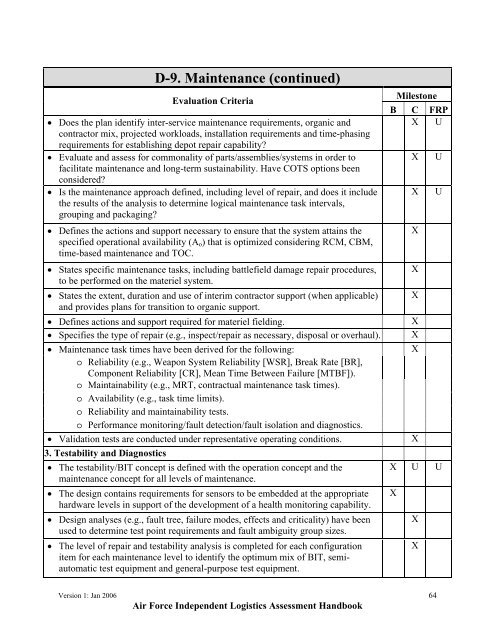

D-9. Maintenance (continued)<br />

Evaluation Criteria<br />

• Does the plan identify inter-service maintenance requirements, organic and<br />

contractor mix, projected workloads, installation requirements and time-phasing<br />

requirements for establishing depot repair capability<br />

• Evaluate and assess for commonality of parts/assemblies/systems in order to<br />

facilitate maintenance and long-term sustainability. Have COTS options been<br />

considered<br />

• Is the maintenance approach defined, including level of repair, and does it include<br />

the results of the analysis to determine logical maintenance task intervals,<br />

grouping and packaging<br />

• Defines the actions and support necessary to ensure that the system attains the<br />

specified operational availability (A o ) that is optimized considering RCM, CBM,<br />

time-based maintenance and TOC.<br />

• States specific maintenance tasks, including battlefield damage repair procedures,<br />

to be performed on the materiel system.<br />

• States the extent, duration and use of interim contractor support (when applicable)<br />

and provides plans for transition to organic support.<br />

• Defines actions and support required for materiel fielding.<br />

• Specifies the type of repair (e.g., inspect/repair as necessary, disposal or overhaul).<br />

• Maintenance task times have been derived for the following:<br />

o Reliability (e.g., Weapon System Reliability [WSR], Break Rate [BR],<br />

Component Reliability [CR], Mean Time Between Failure [MTBF]).<br />

o Maintainability (e.g., MRT, contractual maintenance task times).<br />

o Availability (e.g., task time limits).<br />

o Reliability and maintainability tests.<br />

o Performance monitoring/fault detection/fault isolation and diagnostics.<br />

• Validation tests are conducted under representative operating conditions.<br />

3. Testability and Diagnostics<br />

• The testability/BIT concept is defined with the operation concept and the<br />

maintenance concept for all levels of maintenance.<br />

• The design contains requirements for sensors to be embedded at the appropriate<br />

hardware levels in support of the development of a health monitoring capability.<br />

• Design analyses (e.g., fault tree, failure modes, effects and criticality) have been<br />

used to determine test point requirements and fault ambiguity group sizes.<br />

• The level of repair and testability analysis is completed for each configuration<br />

item for each maintenance level to identify the optimum mix of BIT, semiautomatic<br />

test equipment and general-purpose test equipment.<br />

Milestone<br />

B C FRP<br />

X U<br />

X U<br />

X U<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X U U<br />

X<br />

X<br />

X<br />

Version 1: Jan 2006 64<br />

Air Force Independent Logistics Assessment <strong>Handbook</strong>