USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

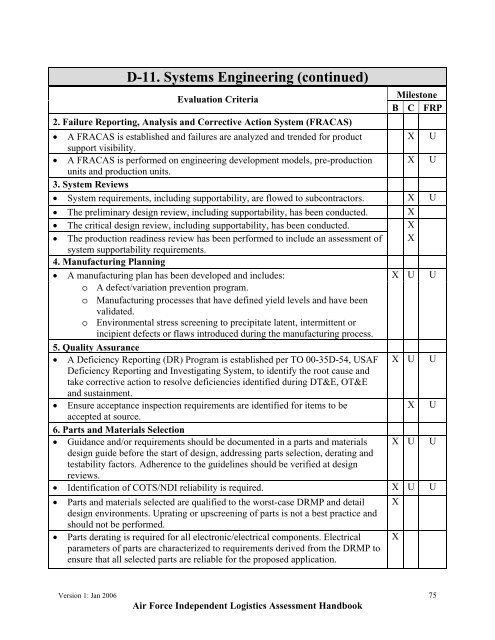

D-11. Systems Engineering (continued)<br />

Evaluation Criteria<br />

2. Failure Reporting, Analysis and Corrective Action System (FRACAS)<br />

Milestone<br />

B C FRP<br />

• A FRACAS is established and failures are analyzed and trended for product X U<br />

support visibility.<br />

• A FRACAS is performed on engineering development models, pre-production X U<br />

units and production units.<br />

3. System Reviews<br />

• System requirements, including supportability, are flowed to subcontractors. X U<br />

• The preliminary design review, including supportability, has been conducted. X<br />

• The critical design review, including supportability, has been conducted. X<br />

• The production readiness review has been performed to include an assessment of X<br />

system supportability requirements.<br />

4. Manufacturing Planning<br />

• A manufacturing plan has been developed and includes: X U U<br />

o A defect/variation prevention program.<br />

o Manufacturing processes that have defined yield levels and have been<br />

validated.<br />

o Environmental stress screening to precipitate latent, intermittent or<br />

incipient defects or flaws introduced during the manufacturing process.<br />

5. Quality Assurance<br />

• A Deficiency Reporting (DR) Program is established per TO 00-35D-54, <strong>USAF</strong> X U U<br />

Deficiency Reporting and Investigating System, to identify the root cause and<br />

take corrective action to resolve deficiencies identified during DT&E, OT&E<br />

and sustainment.<br />

• Ensure acceptance inspection requirements are identified for items to be<br />

X U<br />

accepted at source.<br />

6. Parts and Materials Selection<br />

• Guidance and/or requirements should be documented in a parts and materials X U U<br />

design guide before the start of design, addressing parts selection, derating and<br />

testability factors. Adherence to the guidelines should be verified at design<br />

reviews.<br />

• Identification of COTS/NDI reliability is required. X U U<br />

• Parts and materials selected are qualified to the worst-case DRMP and detail X<br />

design environments. Uprating or upscreening of parts is not a best practice and<br />

should not be performed.<br />

• Parts derating is required for all electronic/electrical components. Electrical<br />

parameters of parts are characterized to requirements derived from the DRMP to<br />

ensure that all selected parts are reliable for the proposed application.<br />

X<br />

Version 1: Jan 2006 75<br />

Air Force Independent Logistics Assessment <strong>Handbook</strong>