USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

USAF ILA Handbook - ACC Practice Center - Defense Acquisition ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

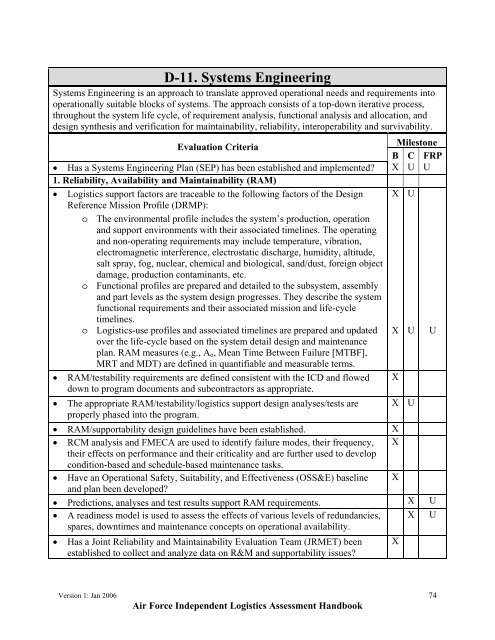

D-11. Systems Engineering<br />

Systems Engineering is an approach to translate approved operational needs and requirements into<br />

operationally suitable blocks of systems. The approach consists of a top-down iterative process,<br />

throughout the system life cycle, of requirement analysis, functional analysis and allocation, and<br />

design synthesis and verification for maintainability, reliability, interoperability and survivability.<br />

Evaluation Criteria<br />

Milestone<br />

B C FRP<br />

• Has a Systems Engineering Plan (SEP) has been established and implemented X U U<br />

1. Reliability, Availability and Maintainability (RAM)<br />

• Logistics support factors are traceable to the following factors of the Design X U<br />

Reference Mission Profile (DRMP):<br />

o The environmental profile includes the system’s production, operation<br />

and support environments with their associated timelines. The operating<br />

and non-operating requirements may include temperature, vibration,<br />

electromagnetic interference, electrostatic discharge, humidity, altitude,<br />

salt spray, fog, nuclear, chemical and biological, sand/dust, foreign object<br />

damage, production contaminants, etc.<br />

o Functional profiles are prepared and detailed to the subsystem, assembly<br />

and part levels as the system design progresses. They describe the system<br />

functional requirements and their associated mission and life-cycle<br />

timelines.<br />

o Logistics-use profiles and associated timelines are prepared and updated X U U<br />

over the life-cycle based on the system detail design and maintenance<br />

plan. RAM measures (e.g., A o , Mean Time Between Failure [MTBF],<br />

MRT and MDT) are defined in quantifiable and measurable terms.<br />

• RAM/testability requirements are defined consistent with the ICD and flowed X<br />

down to program documents and subcontractors as appropriate.<br />

• The appropriate RAM/testability/logistics support design analyses/tests are X U<br />

properly phased into the program.<br />

• RAM/supportability design guidelines have been established. X<br />

• RCM analysis and FMECA are used to identify failure modes, their frequency, X<br />

their effects on performance and their criticality and are further used to develop<br />

condition-based and schedule-based maintenance tasks.<br />

• Have an Operational Safety, Suitability, and Effectiveness (OSS&E) baseline X<br />

and plan been developed<br />

• Predictions, analyses and test results support RAM requirements. X U<br />

• A readiness model is used to assess the effects of various levels of redundancies, X U<br />

spares, downtimes and maintenance concepts on operational availability.<br />

• Has a Joint Reliability and Maintainability Evaluation Team (JRMET) been<br />

established to collect and analyze data on R&M and supportability issues<br />

X<br />

Version 1: Jan 2006 74<br />

Air Force Independent Logistics Assessment <strong>Handbook</strong>