Repair Kits Available By Part Number Section 2 Page - GAMECO

Repair Kits Available By Part Number Section 2 Page - GAMECO

Repair Kits Available By Part Number Section 2 Page - GAMECO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WARNING: Installation, usage and maintenance of this product<br />

must be in compliance with all Engineered Controls International,<br />

Inc. instructions as well as requirements and provisions of NFPA<br />

#54, NFPA #58, DOT and all applicable federal, state, provincial<br />

and local standards, codes, rules, regulations and laws.<br />

Inspection and maintenance on a periodic basis is essential.<br />

Installation and maintenance should be performed only by qualified<br />

personnel.<br />

Be sure all instructions are read and understood before installation<br />

and operation.<br />

CAUTION: Contact or inhalation of liquid propane, ammonia and<br />

their vapors can cause serious injury or death! NH3 and LP-Gas<br />

must be released outdoors in air currents that will insure dispersion<br />

to prevent exposure to people and livestock. LP-Gas must be kept<br />

far enough from any open flame or other source of ignition to<br />

prevent fire or explosion! LP-Gas is heavier than air and will not<br />

disperse or evaporate rapidly if released in still air.<br />

Foreword<br />

The A3209PA Pneumatic Actuator is designed especially for use with<br />

the A3209A Series Internal Valves. It is designed to provide a convenient<br />

means for opening and closing the valve from a remote location.<br />

Responsibility for proper installation must be met by the installer.<br />

How the Pneumatic Actuator Works<br />

The pneumatic actuator can be pressurized with either air or nitrogen.<br />

The actuator’s diaphragm rod moves the valve’s operating lever to the<br />

open position when pressure is applied. Upon loss of pressure, the<br />

valve’s operation lever returns to the closed position. The A3209PA<br />

operates with a minimum pressure of 50 psig and a maximum operation<br />

pressure of 250 psig.<br />

The A3209PA pneumatic actuator is compatible with existing air interlock<br />

systems. It also provides a convenient means of operating a<br />

number of internal valves on stationary storage tanks at bulk plants from<br />

remote locations.<br />

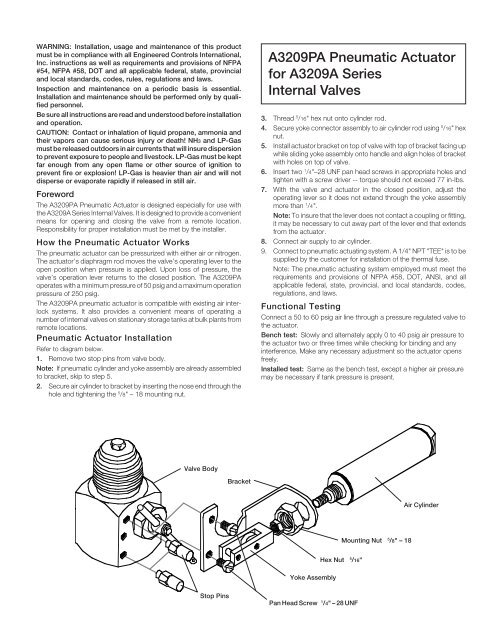

Pneumatic Actuator Installation<br />

Refer to diagram below.<br />

1. Remove two stop pins from valve body.<br />

Note: If pneumatic cylinder and yoke assembly are already assembled<br />

to bracket, skip to step 5.<br />

2. Secure air cylinder to bracket by inserting the nose end through the<br />

hole and tightening the 5 /8" – 18 mounting nut.<br />

A3209PA Pneumatic Actuator<br />

for A3209A Series<br />

Internal Valves<br />

3. Thread 5 /16" hex nut onto cylinder rod.<br />

4. Secure yoke connector assembly to air cylinder rod using 5 /16" hex<br />

nut.<br />

5. Install actuator bracket on top of valve with top of bracket facing up<br />

while sliding yoke assembly onto handle and align holes of bracket<br />

with holes on top of valve.<br />

6. Insert two 1 /4"–28 UNF pan head screws in appropriate holes and<br />

tighten with a screw driver -- torque should not exceed 77 in-lbs.<br />

7. With the valve and actuator in the closed position, adjust the<br />

operating lever so it does not extend through the yoke assembly<br />

more than 1 /4".<br />

Note: To insure that the lever does not contact a coupling or fitting,<br />

it may be necessary to cut away part of the lever end that extends<br />

from the actuator.<br />

8. Connect air supply to air cylinder.<br />

9. Connect to pneumatic actuating system. A 1/4" NPT "TEE" is to be<br />

supplied by the customer for installation of the thermal fuse.<br />

Note: The pneumatic actuating system employed must meet the<br />

requirements and provisions of NFPA #58, DOT, ANSI, and all<br />

applicable federal, state, provincial, and local standards, codes,<br />

regulations, and laws.<br />

Functional Testing<br />

Connect a 50 to 60 psig air line through a pressure regulated valve to<br />

the actuator.<br />

Bench test: Slowly and alternately apply 0 to 40 psig air pressure to<br />

the actuator two or three times while checking for binding and any<br />

interference. Make any necessary adjustment so the actuator opens<br />

freely.<br />

Installed test: Same as the bench test, except a higher air pressure<br />

may be necessary if tank pressure is present.<br />

Valve Body<br />

Bracket<br />

Air Cylinder<br />

Mounting Nut 5<br />

/8" – 18<br />

Hex Nut 5<br />

/16"<br />

Yoke Assembly<br />

Stop Pins<br />

Pan Head Screw 1<br />

/4" – 28 UNF