Repair Kits Available By Part Number Section 2 Page - GAMECO

Repair Kits Available By Part Number Section 2 Page - GAMECO

Repair Kits Available By Part Number Section 2 Page - GAMECO

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WARNING: Installation, disassembly, repair and maintenance must<br />

be performed only by qualified personnel.<br />

Complete maintenance should be performed only after all gas has<br />

been evacuated from the system and container. Remove the entire<br />

valve before performing repairs, except as noted below.<br />

Emergency service, on the actuator and lower stem assembly<br />

portion of the valve only, may be carried out with the valve installed,<br />

provided downstream pressure is relieved under the same conditions<br />

required for releasing LP-Gas, as in the caution below, and<br />

that there is positive assurance that the valve is closed tight with<br />

no leakage past the seats.<br />

Installation, usage and maintenance of this product must be in<br />

compliance with all Engineered Controls International, Inc. instructions<br />

as well as requirements and provisions of NFPA #54, NFPA<br />

#58, DOT, ANSI, all applicable federal, state, provincial and local<br />

standards, codes, regulations and laws.<br />

Inspection and maintenance on a periodic basis is essential.<br />

Be sure all instructions are read and understood before installation,<br />

operation and maintenance. These instructions must be<br />

passed along to the end user of the product.<br />

CAUTION: Contact or inhalation of liquid propane, ammonia and<br />

their vapors can cause serious injury or death! NH3 and LP-Gas<br />

must be released outdoors in air currents that will insure dispersion<br />

to prevent exposure to people and livestock. LP-Gas must be kept<br />

far enough from any open flame or other source of ignition to<br />

prevent fire or explosion! LP-Gas is heavier than air and may not<br />

disperse or evaporate rapidly if released in still air.<br />

Disassembly and <strong>Repair</strong> Procedure<br />

CAUTION: READ THROUGH ALL OF THESE INSTRUCTIONS, IN-<br />

CLUDING THE NOTICE AND WARNINGS ON THE BACK OF THIS<br />

SHEET, BEFORE BEGINNING ANY DISASSEMBLY OR REPAIR.<br />

NOTE: Before repairing valve, thoroughly examine valve lever and all<br />

associated parts for excessive wear. Check lever for proper function and<br />

threads for excessive wear and damage. Any components that are not in<br />

good condition and fully operational should be replaced during repairs.<br />

<strong>Repair</strong>s must be performed in a clean area. Hands, clothing, tools and<br />

work area must be completely free of oil, grease and foreign matter to<br />

prevent contamination of component parts and valves. Clean the valve<br />

body and all parts before assembly.<br />

Disassembly<br />

Actuator / Lower Stem Assembly—<br />

1. Clamp the valve body horizontally in a vise with the actuator portion<br />

overhanging the end of the vise and the outlet facing upwards. Be<br />

careful not to clamp by the threads.<br />

2. Loosen the three (3) hex screws and remove the entire lever housing<br />

assembly. Set aside for reassembly.<br />

3. Remove the lower retaining ring, cup washer and external return<br />

spring from the lower stem by first pushing down on the cup washer<br />

and/or spring to expose the ring and then disengage the ring.<br />

Discard the retaining ring and save the spring and cup washer for<br />

reassembly.<br />

4. Using a 13 /16" wrench, completely loosen and remove the seal<br />

housing. The entire stem assembly may come out at this time. If not,<br />

work through the outlet opening of the body while pulling on the<br />

lower stem to remove it and the bushing.<br />

5. Remove the two (2) seal rings, the jam ring and o-ring from the seal<br />

housing and discard. Save the washer for reassembly.<br />

6. Remove the bushing and upper retaining ring from the lower stem<br />

and discard.<br />

7. Remove the gasket from the body and discard.<br />

8. Retain the washer and packing spring for reassembly.<br />

9. Check the lower stem [A3210-2] for excessive wear and/or damage,<br />

especially in the seal ring area. Replace if necessary.<br />

Seat Disc/Body Assembly—<br />

1. Hold the hex of the upper stem with a 3 /8" socket working from the<br />

lower stem opening of the valve body. Remove the disc retaining<br />

screw, being careful to hold down the main seat disc assembly as<br />

it is spring loaded and will pop off suddenly. Retain the disc retaining<br />

screw for reassembly.<br />

A3210A-50 <strong>Repair</strong> Kit<br />

for A3210A Series<br />

1 1 /4" Angle Internal Valves<br />

2. Remove and discard the main seat disc assembly. Remove and<br />

retain the excess flow spring.<br />

3. Remove and retain the upper stem and internal return spring.<br />

4. Remove the seat disc from the disc retaining screw. Discard the<br />

seat disc.<br />

5. Check the upper stem [A3210-10] for excessive wear. Replace if<br />

necessary.<br />

Reassembly<br />

Seat Disc/Body Assembly—<br />

1. Assemble the new seat disc onto the disc retaining screw.<br />

2. Apply a thin coat of #11550-215 compound to the upper stem.<br />

3. Place the internal return spring over the upper stem. Holding the<br />

upper stem with a 3 /8" socket, guide it into the valve body through<br />

the lower stem opening of the valve body.<br />

4. While a third hand pushes the upper stem forward through the valve<br />

guide at the inlet, reassemble the excess flow spring and new main<br />

seat disc assembly onto the protruding end of the upper stem and<br />

hold in place for step five.<br />

5. Apply #11550-571 compound to the threads of the disc retaining<br />

screw and screw it into the end of the upper stem. Torque down to<br />

40-45 in/lbs.<br />

CAUTION: Do not allow #11550-571 compound to contact seat<br />

disc. Use sparingly.<br />

6. Check for smooth operation of the upper stem and proper seating<br />

of the springs by pushing on the lower stem to open and close the<br />

seats.<br />

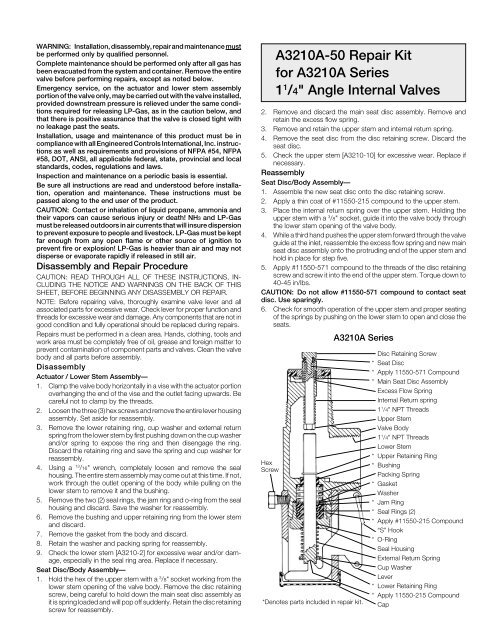

A3210A Series<br />

Hex<br />

Screw<br />

*Denotes parts included in repair kit.<br />

Disc Retaining Screw<br />

* Seat Disc<br />

* Apply 11550-571 Compound<br />

* Main Seat Disc Assembly<br />

Excess Flow Spring<br />

Internal Return spring<br />

1 1 /4" NPT Threads<br />

Upper Stem<br />

Valve Body<br />

1 1 /4" NPT Threads<br />

Lower Stem<br />

* Upper Retaining Ring<br />

* Bushing<br />

Packing Spring<br />

* Gasket<br />

Washer<br />

* Jam Ring<br />

* Seal Rings (2)<br />

* Apply #11550-215 Compound<br />

“S” Hook<br />

* O-Ring<br />

Seal Housing<br />

External Return Spring<br />

Cup Washer<br />

Lever<br />

* Lower Retaining Ring<br />

* Apply 11550-215 Compound<br />

Cap