Space Grant Consortium - University of Wisconsin - Green Bay

Space Grant Consortium - University of Wisconsin - Green Bay

Space Grant Consortium - University of Wisconsin - Green Bay

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

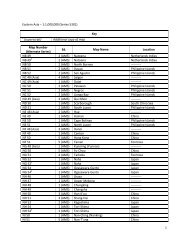

UA<br />

m�<br />

⎛ ε −1<br />

⎞<br />

( c nd c st MR<br />

2 , pc, i 1 , pc, i ) ⎜ ⎟ ( Crpci<br />

, , )<br />

pc, i pc, i<br />

2<br />

nd<br />

= min , ln −1<br />

⎜εC−1⎟ ⎝ pc, i r, pc, i ⎠<br />

where Cr,pc,i is the capacity ratio characterizing the section:<br />

( nd st ) ( nd st )<br />

rpci , , 2 , pc, i 1 , pc, i 2 , pc, i 1 , pc, i<br />

i = 1… Npc (21)<br />

C = min c , c MR max c , c MR i = 1… Npc (22)<br />

The overall conductance <strong>of</strong> the precooler per unit <strong>of</strong> 2 nd stage mass flow rate is computed by<br />

summing the conductances <strong>of</strong> each <strong>of</strong> the segments.<br />

UA N<br />

pc UApc,<br />

i<br />

= ∑<br />

i = 1... Npc (23)<br />

m� m�<br />

2 i=<br />

1 2<br />

nd nd<br />

2 nd Stage Analysis. The thermodynamic states <strong>of</strong> the 2 nd stage, the refrigeration load, and the<br />

temperature distribution in the recuperator are solved using a process similar to that described in<br />

the 1 st stage analysis. The solution process is nearly the same as that <strong>of</strong> the single stage MGJT<br />

cycle presented in [0]. The only difference is that here, the high pressure gas mixture is<br />

precooled before entering the recuperator, whereas in the single stage system the high pressure<br />

gas mixture enters the recuperator near ambient temperature.<br />

− is iteratively adjusted to achieve a<br />

The recuperator hot end temperature difference ( T T )<br />

4 7<br />

specified recuperator pinch point temperature difference (∆Tpp,rec). The load temperature (T7) is<br />

specified and isenthalpic expansion is assumed across the expansion valve. A numerical model<br />

<strong>of</strong> the recuperator was created by dividing it into sections <strong>of</strong> equal heat transfer to calculate an<br />

enthalpy distribution. The enthalpies at states 1, 4, 5, and 7 are used as boundary conditions for<br />

the numerical recuperator model. The enthalpy distribution and recuperator pressures (Ph,2nd and<br />

Pl,2nd) are used to calculate a temperature distribution that facilitates the calculation <strong>of</strong> mixture<br />

heat capacities and recuperator conductance (UArec).<br />

Overall Thermodynamic Analysis – figures <strong>of</strong> Merit. The overall system performance can be<br />

quantified using several figures <strong>of</strong> merit <strong>of</strong> importance to a MGJT system. From a heat<br />

exchanger size standpoint, an optimal MGJT system is small and generates a large amount <strong>of</strong><br />

cooling power. Therefore an appropriate figure <strong>of</strong> merit [0] that is used to optimize the system is<br />

the total cooling load provided per total heat exchanger conductance, which is indicative <strong>of</strong> the<br />

heat exchanger size.<br />

Q� load UAtotal = ( Q� load m� nd<br />

2 ) ( UArec m� nd + UA nd<br />

2 pc m�<br />

2 )<br />

(24)<br />

It is also <strong>of</strong> interest to reduce the size <strong>of</strong> the other hardware required; particularly the<br />

compressors. The compressors can be connected to the heat exchangers via flexible tubing and<br />

physically decoupled from the precooling and recuperative heat exchangers. Therefore, the size<br />

<strong>of</strong> the compressors is less important than the size <strong>of</strong> these heat exchangers. However, the size <strong>of</strong><br />

the compressors largely dictates the size and weight <strong>of</strong> the enclosure that houses the<br />

compressors, as well as the 2 nd stage aftercooler, and 1 st stage condenser. Smaller compressors<br />

will therefore lead to a small system that can more readily be integrated with flight payloads.<br />

The compressor suction side flow rate determines the required displaced volume and therefore,<br />

to first order, the size <strong>of</strong> the compressor. The figure <strong>of</strong> merit that captures the combined<br />

compressor size is the refrigeration load per unit <strong>of</strong> total compressor displacement:<br />

34