Space Grant Consortium - University of Wisconsin - Green Bay

Space Grant Consortium - University of Wisconsin - Green Bay

Space Grant Consortium - University of Wisconsin - Green Bay

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

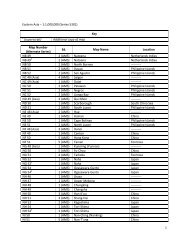

The chambers were sealed and baked at 120±5ºF for 24 hours, after which analysis could be<br />

peformed. An alkane standard was run on both gas chromatographs (GCs) before running the<br />

actual samples to ensure proper instrument performance. Samples were also allowed to cool to<br />

room temperature before analysis, around 75ºF. For the Autosystem, 2.0cm 3 <strong>of</strong> headspace<br />

sample was injected, while 1.0cm 3 was injected for the 6890, both in duplicate. Standard toxic<br />

lab procedures were used for all runs. When samples were taken from the chambers to be<br />

analyzed, the syringe was rinsed at least three times with sample before injecting into the GC.<br />

Two 2.0cm 3 syringes were used for all the transfers as they were graduated and could be used to<br />

accommodate both injection volumes. For identification purposes each <strong>of</strong> the three samples was<br />

run on GC-MS as well. A similar procedure was also used to look at the interactions between<br />

108193 and Mix 1. The difference was 50μL <strong>of</strong> Mix 1 was used in each <strong>of</strong> the two chambers<br />

opposed to unequal Mix volumes.<br />

To determine response factors 10μL <strong>of</strong> Mix 1 was added to a purged 1.00L test chamber and<br />

baked overnight. After cooling the chamber to room temperature four 1.0cm 3 samples were run<br />

on the Agilent 6890 GC/FID and three 2.0cm 3 samples were run on the Autosystem GC/FID.<br />

Following these runs 10μL <strong>of</strong> Mix 2 was added to the chamber and after baking for four hours<br />

and cooling once again, three 1.0cc samples were run on the Agilent 6890 GC/FID and three<br />

2.0cm 3 samples were run on the Autosystem GC/FID. The chamber was purged with high<br />

quality air and 10uL <strong>of</strong> Mix 2 was added to the chamber. After allowing it to bake overnight<br />

four 1.0cc samples were run on the Agilent 6890/FID and three 2.0cm 3 samples were run on the<br />

Autosystem GC/FID. To identify peaks 40mL samples <strong>of</strong> Mix 1, Mix 2, and Mixes 1 and 2<br />

combined were run on the Incos GC-MS.<br />

In a 1.00L test chamber 10μL <strong>of</strong> Mix 1 was added and baked for four hours. After cooling to<br />

ambient room temperature 100μL <strong>of</strong> the sample was injected in the Autosystem GC/FID. The<br />

resulting peaks were too large, and a 25μL sample was run, which resulted in too small <strong>of</strong> peaks.<br />

When a 50uL sample was run the peaks were ideal. Seven trials were run using one syringe for<br />

both injections because one <strong>of</strong> the two 50μL syringes had poor airflow. The same procedure was<br />

used in analyzing Mix 2 and six sets <strong>of</strong> data were taken for it. Incos GC-MS spectra from<br />

previous experiments were used for identification <strong>of</strong> peaks. To quantify the detection limits an<br />

Excel template was used.<br />

The first sample tested was log number 108148, a green foam. A 5.0g sample was placed in a<br />

1.00L chamber and baked for 24 hours after which it was removed from the oven and a 1.0μL<br />

sample was injected into the Autosystem GC/FID three minutes later. Four more samples were<br />

injected at approximately 48 minute intervals as soon as the GC cooled. The next day after<br />

removing the chamber from the oven a run was done 19.5 hours later. Times for each run and<br />

the temperature <strong>of</strong> the chamber were recorded at the time samples were injected into the GC. A<br />

60mL sample was also run on the Incos GC-MS after it had cooled for about an hour for<br />

identification purposes.<br />

The next sample analyzed was composite material, log number 107999, three 5.0g white foam<br />

cubes. The same basic procedure was used as before with several exceptions. Room<br />

temperature was also recorded as the temperature fluctuated before, and air conditioning setting<br />

3