Space Grant Consortium - University of Wisconsin - Green Bay

Space Grant Consortium - University of Wisconsin - Green Bay

Space Grant Consortium - University of Wisconsin - Green Bay

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

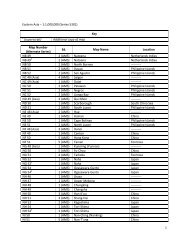

values are determined through toxicological evaluation performed by Johnson <strong>Space</strong> Center<br />

(JSC) Scientists. Most <strong>of</strong>fgass concentrations are found safely below the SMAC value, and a<br />

summation formula for toxicity determines how much material or how many units can be flown<br />

safely. Results are entered into a database, the Materials and Process Technical Information<br />

System (MAPTIS), for future reference.<br />

A number <strong>of</strong> experiments were run to better understand the <strong>of</strong>fgas process, and continue<br />

improving toxicity testing. The main procedure variation was instead <strong>of</strong> baking the chamber for<br />

72 hours the experimental chambers were baked anywhere between 4 and 24 hours to save time.<br />

The first experiment investigated how combining a volatile organic mix solution and flight<br />

material would affect <strong>of</strong>fgassing. The Mix, material, and a combination <strong>of</strong> both were placed in<br />

separate chambers and analyzed by identical methods to look for differences in peak areas.<br />

Limits <strong>of</strong> quantitation (LOQ) tell the minimum amount <strong>of</strong> analyte that can be quantified by a<br />

particular instrument or method. Offgassing must be quantifiable below its SMAC values to<br />

ensure <strong>of</strong>fgassing can be identified before it poses health hazards. Two Mixes were analyzed for<br />

limits <strong>of</strong> quantitation by injecting the smallest volume possible that gave integrable peaks.<br />

A response factor, represented by the letter K, is the ratio <strong>of</strong> compound concentration to the<br />

corresponding peak area. In the past, response factors were calculated with results from flight<br />

hardware, because this was a fast and easy method that gave quality results. In this research<br />

standard volatile organics Mixes were analyzed to compare response factors to standard solutions<br />

as opposed to test data, as well as the difference between the GCs, an Agilent 6890 GC/FID and<br />

Autosystem GC/FID.<br />

Under normal toxicity test procedures, samples cool to ambient room temperature before gas<br />

chromatography analysis. Another experiment looks at the effects <strong>of</strong> chamber cooling on peak<br />

area. Peak area should decrease over time as the chamber reaches room temperature. Slight<br />

leaks in the chamber could cause the peak areas to decrease slightly over a long period <strong>of</strong> time<br />

due to <strong>of</strong>fgas loss to the air.<br />

Procedure<br />

Two 5.0g samples <strong>of</strong> material log number 108053 were weighed in weighing boats. Since the<br />

material was a large piece <strong>of</strong> cloth, pieces <strong>of</strong> it were cut until 5.0g was reached. The material<br />

was transferred to 1.00L sealed chambers in the weighing dishes. The chambers had previously<br />

been purged for at least five minutes with high quality air and were examined for seal strength.<br />

Gloves were worn while handling the sample material. A syringe was rinsed once with Mix 4<br />

and used to transfer Mix 4 to two chambers, 30uL to the chamber that already contained 108053,<br />

and 50uL to the chamber with only a weighing bowl.<br />

Only one rinse with volatile organics Mix 4 was used to clean the syringe to conserve the<br />

chemical mix as quantities were limited. Isopropanol was used to rinse the syringe after the Mix<br />

4 had been transferred to the chambers. When not in use Mix 4 was kept in a refrigerator. For<br />

transferring Mix 4, a syringe that had been baked for at least 24 hours was selected.<br />

2