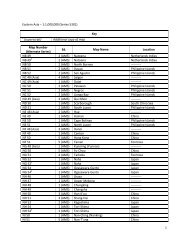

- Page 1 and 2:

Space Grant Consortium wisconsin UN

- Page 3 and 4:

THE CASSINI ENCOUNTER WITH THE GEM

- Page 5:

Th he proceedinngs of our 199th Ann

- Page 8 and 9:

Wisconsin Space Grant Consortium Un

- Page 10 and 11:

Part 3: NASA Reduced Gravity Progra

- Page 12 and 13:

EAA Women Soar - You Soar, Lee Siud

- Page 15 and 16:

Elijah High Altitude Balloon Projec

- Page 17 and 18:

Our experience with the HALO II lau

- Page 19 and 20:

which had been a problem in the pas

- Page 21:

Figure 6: 3-D GPS Generated Track o

- Page 24 and 25:

Results The seeds tested in the lab

- Page 26 and 27:

hour as we assumed the flight in th

- Page 28 and 29:

Experimental Results There are two

- Page 30 and 31:

A series of tests were done in a co

- Page 32 and 33:

380 360 340 320 23.3 Temp. (Celsius

- Page 35 and 36:

First Place, Non-Engineering: Schmi

- Page 37 and 38:

of the basis for fin designs came f

- Page 39 and 40:

ejection charge from the motor fire

- Page 41 and 42:

using rip-stop nylon cloth. To atta

- Page 43 and 44:

Post-flight recovery. A field searc

- Page 45 and 46:

Thus, it is believed that the main

- Page 47:

[2] Public Missiles Ltd. Frequently

- Page 50 and 51:

Design Features The chief requireme

- Page 52 and 53:

The joint between the dart and the

- Page 54 and 55:

Area dramatically influenced by flo

- Page 56 and 57:

Altitude [ft] 6000 5000 4000 3000 2

- Page 58 and 59:

though a strong crosswind was prese

- Page 60 and 61:

Our Design Our rocket uses the basi

- Page 62 and 63:

e easily recovered. Bong recreation

- Page 64 and 65:

Performance Characteristics of Pred

- Page 67 and 68:

Background and Context: Student Roc

- Page 69 and 70: The Rocky Mountain Miners’ compet

- Page 71: 19th Annual Conference Part Three N

- Page 74 and 75: The angle of repose of a granular m

- Page 76 and 77: Experiment Design The experiment co

- Page 78 and 79: on the ground and in the Weightless

- Page 80 and 81: measurements for the 1 − g data.

- Page 82 and 83: [ImageJ, 2008] Image Analysis Softw

- Page 85 and 86: Dynamics Characterization of the El

- Page 87 and 88: Figure 1 - A calibration equation f

- Page 89 and 90: Wire A secondary investigation into

- Page 91: [1] Taminger, K. M. B.; and Hafley,

- Page 94 and 95: Introduction The analysis of wake v

- Page 96 and 97: Figure 2: Screen I mage o f G UI. T

- Page 98 and 99: References ¹ Burnham, D.C., and Ha

- Page 101 and 102: Validation of Novel Rigid Body Fric

- Page 103 and 104: forces is implemented in the popula

- Page 105 and 106: Figure 2. CAD representation of a t

- Page 107 and 108: Results Figure 5. Assembled hydraul

- Page 109: References Anitescu, M. (2006). "Op

- Page 112 and 113: Multi-stage Joule-Thomson cycles ar

- Page 114 and 115: significant change in total compres

- Page 116 and 117: The enthalpy (h3) of the 2 nd stage

- Page 118 and 119: UA m� ⎛ ε −1 ⎞ ( c nd c st

- Page 122 and 123: 7. Lemmon, E. W.; Huber, M. L.; McL

- Page 124 and 125: Throughout each of the run cycles,

- Page 126 and 127: and heater adjusted to accommodate

- Page 129 and 130: Phaeton Mast Dynamics Mechanical Sy

- Page 131 and 132: exposure to the FEMAP with NASTRAN

- Page 133 and 134: The irregularity in the plots above

- Page 135 and 136: inversion of a particular matrix, t

- Page 137: clarified. Additionally, the PMD ki

- Page 140 and 141: A. Abstract For hardware to be flig

- Page 142 and 143: should be performed at the JWST obs

- Page 144 and 145: B. Attenuation and Uncertainty Shoc

- Page 146 and 147: Detector Array and ROIC SCA Mount L

- Page 148 and 149: Detector Shock Environment The leve

- Page 150 and 151: Orbiter (MRO), Moon Mineralogy Mapp

- Page 152 and 153: 4. NASA JPL. MIRI FOCAL PLANE SYSTE

- Page 155 and 156: Is Lake Superior a significant sour

- Page 157 and 158: each grid cell at daily resolution.

- Page 159 and 160: Figure 3. (a) Seasonal cycle of lak

- Page 161 and 162: Figure 5. Model pCO2 at the surface

- Page 163: Marshall, J., A. Adcroft, C. Hill,

- Page 166 and 167: numerical weather prediction (NWP)

- Page 168 and 169: High Resolution Radiometer (AVHRR)

- Page 170 and 171:

On the morning of 26 May 2008, ther

- Page 172 and 173:

References Behnke, C., 2005: Synopt

- Page 174 and 175:

Figure 3 Figure 3 contains base ref

- Page 177 and 178:

A Comparative Study of Type IIb Sup

- Page 179 and 180:

Fig. 3.— Cartoon Image of SN blas

- Page 181 and 182:

Fig. 4.— Light curve of SN 2008bo

- Page 183:

type IIn Supernova SN 1995N,” 200

- Page 190:

and then can spiral in to the black

- Page 195 and 196:

Understanding the Evolution of Supe

- Page 197 and 198:

Radio

measurements

of

supe

- Page 199 and 200:

In

the

equations

on

the

p

- Page 201 and 202:

SN 2008ax in NGC 4490 SN2008ax is a

- Page 203:

References Chevalier, R. A., “Int

- Page 207 and 208:

Computational Fluid Dynamical Model

- Page 209 and 210:

context of the k − ɛ model invol

- Page 211 and 212:

Figure 3: Experimental results (•

- Page 213 and 214:

direction results in the terminal s

- Page 215:

121 (2000). [Blue Ridge Numerics, I

- Page 218 and 219:

concentrated our effort specificall

- Page 220 and 221:

density, and Ps is a pressure tenso

- Page 222 and 223:

Properties of the GEM problem Recon

- Page 224 and 225:

Figure 1: Increase in reconnection

- Page 226 and 227:

Figure 3: Examples of agreement of

- Page 229 and 230:

Reflection and Refraction of Vortex

- Page 231 and 232:

Experimental Procedure The left han

- Page 233 and 234:

frames in the upper left corner, wh

- Page 235 and 236:

Vortex ring reflection. Similarly,

- Page 237:

References L Bernal and J Kwon. Vor

- Page 240 and 241:

group started in 1997 with the goal

- Page 242 and 243:

I conducted five semi-structured in

- Page 244 and 245:

In the example of the guinea pig pr

- Page 246 and 247:

explain t his t rend. F rom t alkin

- Page 248 and 249:

Research. Washington, DC: Pan Ameri

- Page 250 and 251:

Our team has two goals: 1. To put S

- Page 252 and 253:

fluctuating humidity, drying winds,

- Page 254 and 255:

western border of the Arkansas Rive

- Page 256 and 257:

adjusted to less than .4millisecond

- Page 258 and 259:

Cacti Experiment 18 has produced 10

- Page 260:

13. What N decomposer's are needed

- Page 265 and 266:

Abstract Toxic Offgassing Analysis

- Page 267 and 268:

The chambers were sealed and baked

- Page 269 and 270:

Tables 4 and 5 show offgassing comp

- Page 271:

there was no dichlorobenzene peak.

- Page 274 and 275:

eneficiation reagents. Ionic liquid

- Page 276 and 277:

Figure 3: Current versus voltage da

- Page 279 and 280:

Abstract New Initiatives in the Pro

- Page 281 and 282:

was noticed above the gel. A discol

- Page 283 and 284:

delicate structures (hairs). N o fu

- Page 285:

and A. Y. Rozanov, Eds., SPIE, Vol.

- Page 289 and 290:

Combining Writing Across the Curric

- Page 291 and 292:

But the study also reported a consi

- Page 293 and 294:

Educators’ Aerospace Workshop for

- Page 295 and 296:

2008-2009 Evaluation Educators’ A

- Page 297:

Some comments from participants 200

- Page 300 and 301:

The cost of a one credit graduate c

- Page 303:

EAA WOMEN SOAR - YOU SOAR Dr. Lee J

- Page 306 and 307:

� Incorporated the technology res

- Page 308 and 309:

Evaluation Results: At the conclusi

- Page 310 and 311:

Educational Standards: The National

- Page 312 and 313:

curriculum development, to provide

- Page 314 and 315:

and applications of GIS technology

- Page 316 and 317:

• A significant new outcome for t

- Page 318 and 319:

The design of this project and appl

- Page 320 and 321:

Activities at the workshop involved

- Page 322 and 323:

to give our students a series of PR

- Page 324 and 325:

In the past we have not focused on

- Page 327 and 328:

Providing High School Students with

- Page 329 and 330:

that th e current generations of s

- Page 331:

instruction a s pa rt o f t heir ow

- Page 335 and 336:

Wisconsin Space Grant Consortium &

- Page 337 and 338:

11:45-1:00 pm Lunch *** Concurrent

- Page 339 and 340:

Moderator: David B lock, A ssociate

- Page 341 and 342:

Second Place, E ngineering, Drew an

- Page 343:

Wisconsin Space Grant Consortium