You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LIST OF ATTACHMENTSSTRUCTURAL ANALYSIS OF BLADES<br />

150<br />

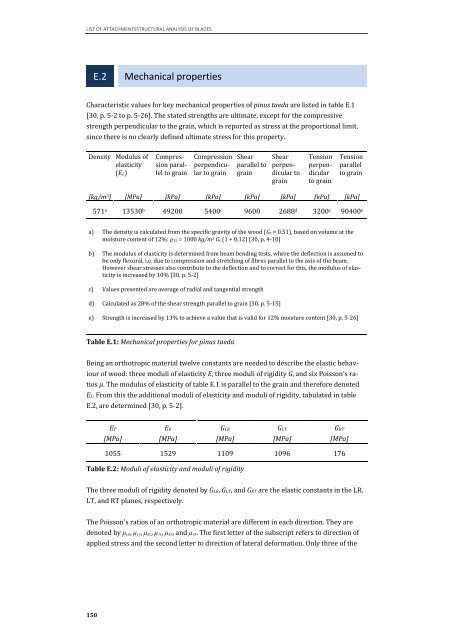

E.2 Mechanical properties<br />

Characteristic values for key mechanical properties of pinus taeda are listed in table E.1<br />

[30, p. 5-2 to p. 5-26]. The stated strengths are ultimate, except for the compressive<br />

strength perpendicular to the grain, which is reported as stress at the proportional limit,<br />

<strong>sin</strong>ce there is no clearly defined ultimate stress for this property.<br />

Density<br />

[kg/m 3]<br />

Modulus of<br />

elasticity<br />

(EL)<br />

[MPa]<br />

Compressionparallel<br />

to grain<br />

[kPa]<br />

Compression<br />

perpendicular<br />

to grain<br />

[kPa]<br />

Shear<br />

parallel to<br />

grain<br />

[kPa]<br />

Shear<br />

perpendicular<br />

to<br />

grain<br />

[kPa]<br />

Tension<br />

perpendicular<br />

to grain<br />

[kPa]<br />

Tension<br />

parallel<br />

to grain<br />

[kPa]<br />

571 a 13530 b 49200 5400 c 9600 2688 d 3200 c 90400 e<br />

a) The density is calculated from the specific gravity of the wood (Gx = 0.51), based on volume at the<br />

moisture content of 12%: �12 = 1000 kg/m 3 Gx (1 + 0.12) [30, p. 4-10]<br />

b) The modulus of elasticity is determined from beam bending tests, where the deflection is assumed to<br />

be only flexural, i.e. due to compression and stretching of fibres parallel to the axis of the beam.<br />

However shear stresses also contribute to the deflection and to correct for this, the modulus of elasticity<br />

is increased by 10% [30, p. 5-2]<br />

c) Values presented are average of radial and tangential strength<br />

d) Calculated as 28% of the shear strength parallel to grain [30, p. 5-15]<br />

e) Strength is increased by 13% to achieve a value that is valid for 12% moisture content [30, p. 5-26]<br />

Table E.1: Mechanical properties for pinus taeda<br />

Being an orthotropic material twelve constants are needed to describe the elastic behav-<br />

iour of wood: three moduli of elasticity E, three moduli of rigidity G, and six Poisson’s ra-<br />

tios μ. The modulus of elasticity of table E.1 is parallel to the grain and therefore denoted<br />

EL. From this the additional moduli of elasticity and moduli of rigidity, tabulated in table<br />

E.2, are determined [30, p. 5-2].<br />

ET<br />

[MPa]<br />

ER<br />

[MPa]<br />

GLR<br />

[MPa]<br />

GLT<br />

[MPa]<br />

GRT<br />

[MPa]<br />

1055 1529 1109 1096 176<br />

Table E.2: Moduli of elasticity and moduli of rigidity<br />

The three moduli of rigidity denoted by GLR, GLT, and GRT are the elastic constants in the LR,<br />

LT, and RT planes, respectively.<br />

The Poisson's ratios of an orthotropic material are different in each direction. They are<br />

denoted by μLR, μLT, μRL, μTL, μRT, and μTR. The first letter of the subscript refers to direction of<br />

applied stress and the second letter to direction of lateral deformation. Only three of the