You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ROTOR<br />

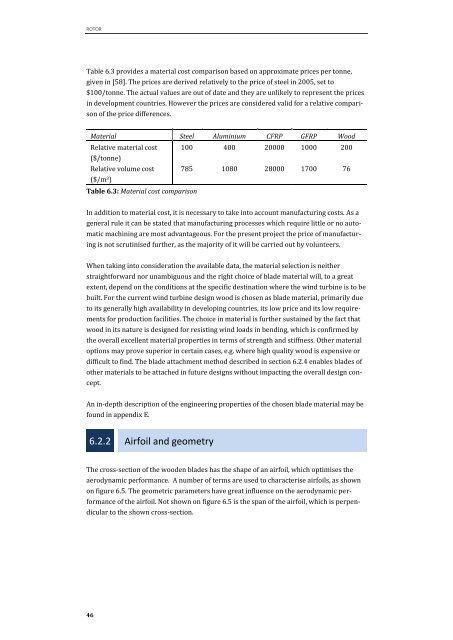

Table 6.3 provides a material cost comparison based on approximate prices per tonne,<br />

given in [58]. The prices are derived relatively to the price of steel in 2005, set to<br />

$100/tonne. The actual values are out of date and they are unlikely to represent the prices<br />

in development countries. However the prices are considered valid for a relative compari-<br />

son of the price differences.<br />

46<br />

Material Steel Aluminium CFRP GFRP Wood<br />

Relative material cost<br />

($/tonne)<br />

Relative volume cost<br />

($/m 3 )<br />

Table 6.3: Material cost comparison<br />

100 400 20000 1000 200<br />

785 1080 28000 1700 76<br />

In addition to material cost, it is necessary to take into account manufacturing costs. As a<br />

general rule it can be stated that manufacturing processes which require little or no auto-<br />

matic machining are most advantageous. For the present project the price of manufactur-<br />

ing is not scrutinised further, as the majority of it will be carried out by volunteers.<br />

When taking into consideration the available data, the material selection is neither<br />

straightforward nor unambiguous and the right choice of blade material will, to a great<br />

extent, depend on the conditions at the specific destination where the wind turbine is to be<br />

built. For the current wind turbine design wood is chosen as blade material, primarily due<br />

to its generally high availability in developing countries, its low price and its low require-<br />

ments for production facilities. The choice in material is further sustained by the fact that<br />

wood in its nature is designed for resisting wind loads in bending, which is confirmed by<br />

the overall excellent material properties in terms of strength and stiffness. Other material<br />

options may prove superior in certain cases, e.g. where high quality wood is expensive or<br />

difficult to find. The blade attachment method described in section 6.2.4 enables blades of<br />

other materials to be attached in future designs without impacting the overall design con-<br />

cept.<br />

An in-depth description of the engineering properties of the chosen blade material may be<br />

found in appendix E.<br />

6.2.2 Airfoil and geometry<br />

The cross-section of the wooden blades has the shape of an airfoil, which optimises the<br />

aerodynamic performance. A number of terms are used to characterise airfoils, as shown<br />

on figure 6.5. The geometric parameters have great influence on the aerodynamic per-<br />

formance of the airfoil. Not shown on figure 6.5 is the span of the airfoil, which is perpen-<br />

dicular to the shown cross-section.