- Page 1 and 2:

WIND TURBINE DESIGN

- Page 3 and 4:

ABSTRACT At the request of the Engi

- Page 5 and 6:

CONTENTS 1 Introduction ...........

- Page 7 and 8:

E Structural analysis of blades ...

- Page 9 and 10:

INTRODUCTION members. Today EWB-DK

- Page 11 and 12: INTRODUCTION Figure 1.2: Left pictu

- Page 13 and 14: INTRODUCTION 6

- Page 15 and 16: PROBLEM STATEMENT reconfigured with

- Page 17 and 18: PROBLEM STATEMENT 10

- Page 19 and 20: METHODOLOGY Figure 3.1: Flow chart

- Page 21 and 22: METHODOLOGY 14 3.1 Calculation meth

- Page 23 and 24: CONCEPTUALISATION the kinetic wind

- Page 25 and 26: CONCEPTUALISATION Figure 4.3: (a) D

- Page 27 and 28: CONCEPTUALISATION issues due to tur

- Page 29 and 30: CONCEPTUALISATION 22 Figure 4.8: Ty

- Page 31 and 32: CONCEPTUALISATION � Darrieus 24 F

- Page 33 and 34: CONCEPTUALISATION 26 Figure 4.13: G

- Page 35 and 36: CONCEPTUALISATION Figure 4.14: Powe

- Page 37 and 38: CONCEPTUALISATION 30 ID Requirement

- Page 39 and 40: CONCEPTUALISATION most suitable sol

- Page 41 and 42: CONCEPTUALISATION The embodiment de

- Page 43 and 44: DESIGN PRESENTATION The main dimens

- Page 45 and 46: DESIGN PRESENTATION The design prop

- Page 47 and 48: DESIGN PRESENTATION The background

- Page 49 and 50: ROTOR 42 6.1 Number of blades Moder

- Page 51 and 52: ROTOR 44 Figure 6.4: Blade design s

- Page 53 and 54: ROTOR Table 6.3 provides a material

- Page 55 and 56: ROTOR Figure 6.7 displays the lift

- Page 57 and 58: ROTOR Figure 6.9: Rotor power outpu

- Page 59 and 60: ROTOR 6.2.3 Manufacturing During th

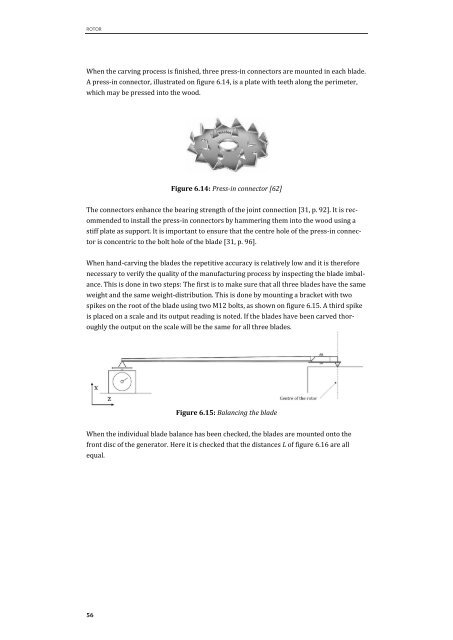

- Page 61: ROTOR 54 The three sides of the tem

- Page 65 and 66: ROTOR 58 Figure 6.17: Blade attachm

- Page 67 and 68: ROTOR 60 Figure 6.19: Rotor power o

- Page 69 and 70: ROTOR 62 Figure 6.22: Efficiency

- Page 71 and 72: ROTOR sidering the output from the

- Page 73 and 74: ROTOR 66

- Page 75 and 76: GENERATOR AND ELECTRICAL SYSTEM 68

- Page 77 and 78: GENERATOR AND ELECTRICAL SYSTEM The

- Page 79 and 80: GENERATOR AND ELECTRICAL SYSTEM Fig

- Page 81 and 82: GENERATOR AND ELECTRICAL SYSTEM 74

- Page 83 and 84: YAW AND FURLING For an upwind wind

- Page 85 and 86: YAW AND FURLING (16), which are bol

- Page 87 and 88: YAW AND FURLING 80 8.2 Furling syst

- Page 89 and 90: YAW AND FURLING 82 8.3 Summary The

- Page 91 and 92: TOWER Concrete tower 84 Figure 9.1:

- Page 93 and 94: TOWER 86 Figure 9.4: Turbulent air

- Page 95 and 96: TOWER Figure 9.7 shows the tower ba

- Page 97 and 98: TOWER models [41, p. 111]. Under ce

- Page 99 and 100: ALTERNATIVE BLADE DESIGN 92 10.1 Ai

- Page 101 and 102: ALTERNATIVE BLADE DESIGN 94 10.3 Su

- Page 103 and 104: DESIGN EVALUATION 96 6 W Low-cost m

- Page 105 and 106: DESIGN EVALUATION Weaknesses 1) The

- Page 107 and 108: FURTHER DEVELOPMENT � Foundation

- Page 109 and 110: FURTHER DEVELOPMENT 102

- Page 111 and 112: CONCLUSION proposal is highly flexi

- Page 113 and 114:

NOMENCLATURE Abbreviation Descripti

- Page 115 and 116:

NOMENCLATURE Lgs Distance between u

- Page 117 and 118:

NOMENCLATURE 110

- Page 119 and 120:

BIBLIOGRAPHY [14] Magenn Power Inc.

- Page 121 and 122:

BIBLIOGRAPHY [53] H. J. Larsen, H.

- Page 123 and 124:

LIST OF ATTACHMENTSBASIS FOR CALCUL

- Page 125 and 126:

LIST OF ATTACHMENTSBASIS FOR CALCUL

- Page 127 and 128:

LIST OF ATTACHMENTSBASIS FOR CALCUL

- Page 129 and 130:

LIST OF ATTACHMENTSBASIS FOR CALCUL

- Page 131 and 132:

LIST OF ATTACHMENTSBASIS FOR CALCUL

- Page 133 and 134:

LIST OF ATTACHMENTSBASIS FOR CALCUL

- Page 135 and 136:

LIST OF ATTACHMENTSBASIS FOR CALCUL

- Page 137 and 138:

LIST OF ATTACHMENTSBASIS FOR CALCUL

- Page 139 and 140:

LIST OF ATTACHMENTSROTOR THEORY Thi

- Page 141 and 142:

LIST OF ATTACHMENTSROTOR THEORY 134

- Page 143 and 144:

LIST OF ATTACHMENTSROTOR THEORY Cho

- Page 145 and 146:

LIST OF ATTACHMENTSROTOR THEORY 138

- Page 147 and 148:

LIST OF ATTACHMENTSROTOR DESIGN TOO

- Page 149 and 150:

LIST OF ATTACHMENTSROTOR DESIGN TOO

- Page 151 and 152:

LIST OF ATTACHMENTSAIRFOIL With the

- Page 153 and 154:

LIST OF ATTACHMENTSAIRFOIL Complete

- Page 155 and 156:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 157 and 158:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 159 and 160:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 161 and 162:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 163 and 164:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 165 and 166:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 167 and 168:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 169 and 170:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 171 and 172:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 173 and 174:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 175 and 176:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 177 and 178:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 179 and 180:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 181 and 182:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 183 and 184:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 185 and 186:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 187 and 188:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 189 and 190:

LIST OF ATTACHMENTSSTRUCTURAL ANALY

- Page 191 and 192:

LIST OF ATTACHMENTSBLADE ATTACHMENT

- Page 193 and 194:

LIST OF ATTACHMENTSBLADE ATTACHMENT

- Page 195 and 196:

LIST OF ATTACHMENTSBLADE ATTACHMENT

- Page 197 and 198:

LIST OF ATTACHMENTSSTRUCTURAL VERIF

- Page 199 and 200:

LIST OF ATTACHMENTSSTRUCTURAL VERIF

- Page 201 and 202:

LIST OF ATTACHMENTSSTRUCTURAL VERIF

- Page 203 and 204:

LIST OF ATTACHMENTSTOWER ANALYSIS T

- Page 205 and 206:

LIST OF ATTACHMENTSTOWER ANALYSIS T

- Page 207 and 208:

LIST OF ATTACHMENTSTOWER ANALYSIS T

- Page 209 and 210:

LIST OF ATTACHMENTSFURLING AND YAW

- Page 211 and 212:

LIST OF ATTACHMENTSFURLING AND YAW

- Page 213 and 214:

LIST OF ATTACHMENTSFURLING AND YAW

- Page 215 and 216:

LIST OF ATTACHMENTSFURLING AND YAW

- Page 217 and 218:

LIST OF ATTACHMENTSFURLING AND YAW

- Page 219 and 220:

LIST OF ATTACHMENTSFURLING AND YAW

- Page 221 and 222:

LIST OF ATTACHMENTSALTERNATIVE AIRF

- Page 223 and 224:

LIST OF ATTACHMENTSALTERNATIVE AIRF

- Page 225 and 226:

LIST OF ATTACHMENTSALTERNATIVE AIRF

- Page 227 and 228:

LIST OF ATTACHMENTSALTERNATIVE AIRF

- Page 229 and 230:

LIST OF ATTACHMENTSALTERNATIVE AIRF

- Page 231:

LIST OF ATTACHMENTSCOMPLIANCE WITH