Complete Report - University of New South Wales

Complete Report - University of New South Wales

Complete Report - University of New South Wales

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

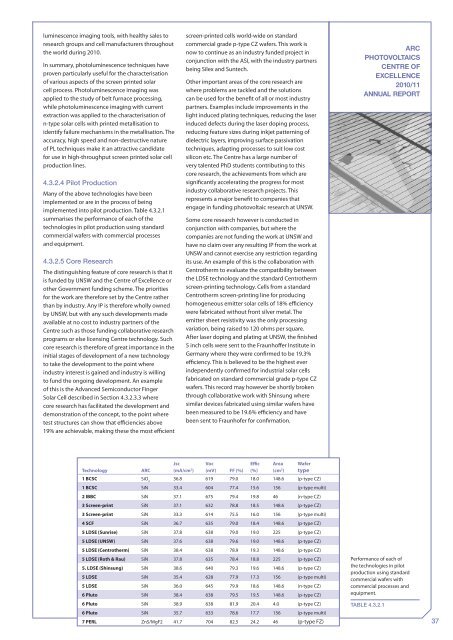

luminescence imaging tools, with healthy sales toresearch groups and cell manufacturers throughoutthe world during 2010.In summary, photoluminescence techniques haveproven particularly useful for the characterisation<strong>of</strong> various aspects <strong>of</strong> the screen printed solarcell process. Photoluminescence imaging wasapplied to the study <strong>of</strong> belt furnace processing,while photoluminescence imaging with currentextraction was applied to the characterisation <strong>of</strong>n-type solar cells with printed metallisation toidentify failure mechanisms in the metallisation. Theaccuracy, high speed and non-destructive nature<strong>of</strong> PL techniques make it an attractive candidatefor use in high-throughput screen printed solar cellproduction lines.4.3.2.4 Pilot ProductionMany <strong>of</strong> the above technologies have beenimplemented or are in the process <strong>of</strong> beingimplemented into pilot production. Table 4.3.2.1summarises the performance <strong>of</strong> each <strong>of</strong> thetechnologies in pilot production using standardcommercial wafers with commercial processesand equipment.4.3.2.5 Core ResearchThe distinguishing feature <strong>of</strong> core research is that itis funded by UNSW and the Centre <strong>of</strong> Excellence orother Government funding scheme. The prioritiesfor the work are therefore set by the Centre ratherthan by industry. Any IP is therefore wholly ownedby UNSW, but with any such developments madeavailable at no cost to industry partners <strong>of</strong> theCentre such as those funding collaborative researchprograms or else licensing Centre technology. Suchcore research is therefore <strong>of</strong> great importance in theinitial stages <strong>of</strong> development <strong>of</strong> a new technologyto take the development to the point whereindustry interest is gained and industry is willingto fund the ongoing development. An example<strong>of</strong> this is the Advanced Semiconductor FingerSolar Cell described in Section 4.3.2.3.3 wherecore research has facilitated the development anddemonstration <strong>of</strong> the concept, to the point wheretest structures can show that efficiencies above19% are achievable, making these the most efficientscreen-printed cells world-wide on standardcommercial grade p-type CZ wafers. This work isnow to continue as an industry funded project inconjunction with the ASI, with the industry partnersbeing Silex and Suntech.Other important areas <strong>of</strong> the core research arewhere problems are tackled and the solutionscan be used for the benefit <strong>of</strong> all or most industrypartners. Examples include improvements in thelight induced plating techniques, reducing the laserinduced defects during the laser doping process,reducing feature sizes during inkjet patterning <strong>of</strong>dielectric layers, improving surface passivationtechniques, adapting processes to suit low costsilicon etc. The Centre has a large number <strong>of</strong>very talented PhD students contributing to thiscore research, the achievements from which aresignificantly accelerating the progress for mostindustry collaborative research projects. Thisrepresents a major benefit to companies thatengage in funding photovoltaic research at UNSW.Some core research however is conducted inconjunction with companies, but where thecompanies are not funding the work at UNSW andhave no claim over any resulting IP from the work atUNSW and cannot exercise any restriction regardingits use. An example <strong>of</strong> this is the collaboration withCentrotherm to evaluate the compatibility betweenthe LDSE technology and the standard Centrothermscreen-printing technology. Cells from a standardCentrotherm screen-printing line for producinghomogeneous emitter solar cells <strong>of</strong> 18% efficiencywere fabricated without front silver metal. Theemitter sheet resistivity was the only processingvariation, being raised to 120 ohms per square.After laser doping and plating at UNSW, the finished5 inch cells were sent to the Fraunh<strong>of</strong>fer Institute inGermany where they were confirmed to be 19.3%efficiency. This is believed to be the highest everindependently confirmed for industrial solar cellsfabricated on standard commercial grade p-type CZwafers. This record may however be shortly brokenthrough collaborative work with Shinsung wheresimilar devices fabricated using similar wafers havebeen measured to be 19.6% efficiency and havebeen sent to Fraunh<strong>of</strong>er for confirmation.ARCPHOTOVOLTAICSCENTRE OFEXCELLENCE2010/11ANNUAL REPORTTechnologyARCJsc(mA/cm 2 )Voc(mV) FF (%)Effic(%)Area(cm 2 )Wafertype1 BCSC SiO 236.8 619 79.0 18.0 148.6 (p-type CZ)1 BCSC SiN 33.4 604 77.4 15.6 156 (p-type multi)2 IBBC SiN 37.1 675 79.4 19.8 46 (n-type CZ)3 Screen-print SiN 37.1 632 78.8 18.5 148.6 (p-type CZ)3 Screen-print SiN 33.3 614 75.5 16.0 156 (p-type multi)4 SCF SiN 36.7 635 79.0 18.4 148.6 (p-type CZ)5 LDSE (Sunrise) SiN 37.8 638 79.0 19.0 225 (p-type CZ)5 LDSE (UNSW) SiN 37.6 638 79.6 19.0 148.6 (p-type CZ)5 LDSE (Centrotherm) SiN 38.4 638 78.9 19.3 148.6 (p-type CZ)5 LDSE (Roth & Rau) SiN 37.8 635 78.4 18.8 225 (p-type CZ)5. LDSE (Shinsung) SiN 38.6 640 79.3 19.6 148.6 (p-type CZ)5 LDSE SiN 35.4 628 77.9 17.3 156 (p-type multi)5 LDSE SiN 36.0 645 79.9 18.6 148.6 (n-type CZ)6 Pluto SiN 38.4 638 79.5 19.5 148.6 (p-type CZ)6 Pluto SiN 38.9 638 81.9 20.4 4.0 (p-type CZ)6 Pluto SiN 35.7 633 78.6 17.7 156 (p-type multi)7 PERL ZnS/MgF2 41.7 704 82.5 24.2 46 (p-type FZ)Performance <strong>of</strong> each <strong>of</strong>the technologies in pilotproduction using standardcommercial wafers withcommercial processes andequipment.table 4.3.2.137