Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

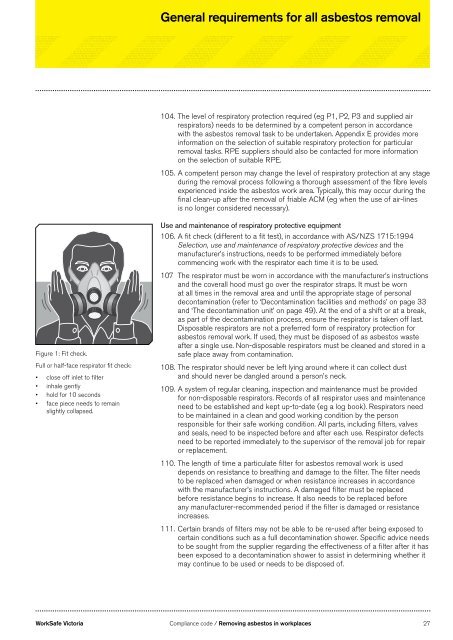

General requirements for all <strong>asbestos</strong> removal104. The level of respiratory protection required (eg P1, P2, P3 and supplied airrespirators) needs to be determ<strong>in</strong>ed by a competent person <strong>in</strong> accordancewith the <strong>asbestos</strong> removal task to be undertaken. Appendix E provides more<strong>in</strong>formation on the selection of suitable respiratory protection for particularremoval tasks. RPE suppliers should also be contacted for more <strong>in</strong>formationon the selection of suitable RPE.105. A competent person may change the level of respiratory protection at any stagedur<strong>in</strong>g the removal process follow<strong>in</strong>g a thorough assessment of the fibre levelsexperienced <strong>in</strong>side the <strong>asbestos</strong> work area. Typically, this may occur dur<strong>in</strong>g thef<strong>in</strong>al clean-up after the removal of friable ACM (eg when the use of air-l<strong>in</strong>esis no longer considered necessary).Figure 1: Fit check.Full or half-face respirator fit check:• close off <strong>in</strong>let to filter• <strong>in</strong>hale gently• hold for 10 seconds• face piece needs to rema<strong>in</strong>slightly collapsed.Use and ma<strong>in</strong>tenance of respiratory protective equipment106. A fit check (different to a fit test), <strong>in</strong> accordance with AS/NZS 1715:1994Selection, use and ma<strong>in</strong>tenance of respiratory protective devices and themanufacturer’s <strong>in</strong>structions, needs to be performed immediately beforecommenc<strong>in</strong>g work with the respirator each time it is to be used.107 The respirator must be worn <strong>in</strong> accordance with the manufacturer’s <strong>in</strong>structionsand the coverall hood must go over the respirator straps. It must be wornat all times <strong>in</strong> the removal area and until the appropriate stage of personaldecontam<strong>in</strong>ation (refer to ‘Decontam<strong>in</strong>ation facilities and methods’ on page 33and ‘The decontam<strong>in</strong>ation unit’ on page 49). At the end of a shift or at a break,as part of the decontam<strong>in</strong>ation process, ensure the respirator is taken off last.Disposable respirators are not a preferred form of respiratory protection for<strong>asbestos</strong> removal work. If used, they must be disposed of as <strong>asbestos</strong> wasteafter a s<strong>in</strong>gle use. Non-disposable respirators must be cleaned and stored <strong>in</strong> asafe place away from contam<strong>in</strong>ation.108. The respirator should never be left ly<strong>in</strong>g around where it can collect dustand should never be dangled around a person’s neck.109. A system of regular clean<strong>in</strong>g, <strong>in</strong>spection and ma<strong>in</strong>tenance must be providedfor non-disposable respirators. Records of all respirator uses and ma<strong>in</strong>tenanceneed to be established and kept up-to-date (eg a log book). Respirators needto be ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> a clean and good work<strong>in</strong>g condition by the personresponsible for their safe work<strong>in</strong>g condition. All parts, <strong>in</strong>clud<strong>in</strong>g filters, valvesand seals, need to be <strong>in</strong>spected before and after each use. Respirator defectsneed to be reported immediately to the supervisor of the removal job for repairor replacement.110. The length of time a particulate filter for <strong>asbestos</strong> removal work is useddepends on resistance to breath<strong>in</strong>g and damage to the filter. The filter needsto be replaced when damaged or when resistance <strong>in</strong>creases <strong>in</strong> accordancewith the manufacturer’s <strong>in</strong>structions. A damaged filter must be replacedbefore resistance beg<strong>in</strong>s to <strong>in</strong>crease. It also needs to be replaced beforeany manufacturer-recommended period if the filter is damaged or resistance<strong>in</strong>creases.111. Certa<strong>in</strong> brands of filters may not be able to be re-used after be<strong>in</strong>g exposed tocerta<strong>in</strong> conditions such as a full decontam<strong>in</strong>ation shower. Specific advice needsto be sought from the supplier regard<strong>in</strong>g the effectiveness of a filter after it hasbeen exposed to a decontam<strong>in</strong>ation shower to assist <strong>in</strong> determ<strong>in</strong><strong>in</strong>g whether itmay cont<strong>in</strong>ue to be used or needs to be disposed of.<strong>WorkSafe</strong> <strong>Victoria</strong> <strong>Compliance</strong> code / <strong>Remov<strong>in</strong>g</strong> <strong>asbestos</strong> <strong>in</strong> <strong>workplaces</strong> 27