Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

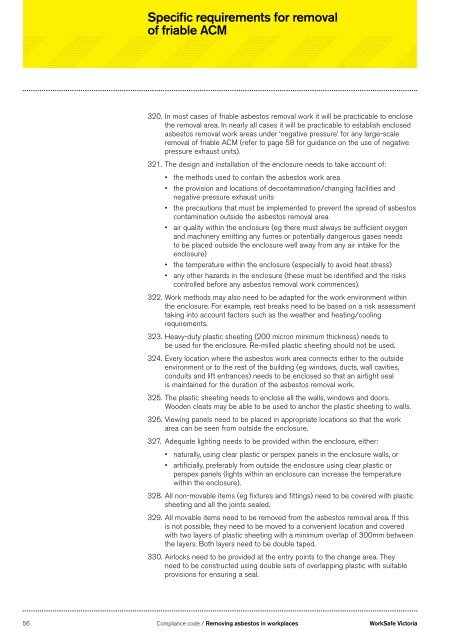

Specific requirements for removalof friable ACM320. In most cases of friable <strong>asbestos</strong> removal work it will be practicable to enclosethe removal area. In nearly all cases it will be practicable to establish enclosed<strong>asbestos</strong> removal work areas under ‘negative pressure’ for any large-scaleremoval of friable ACM (refer to page 58 for guidance on the use of negativepressure exhaust units).321. The design and <strong>in</strong>stallation of the enclosure needs to take account of:• the methods used to conta<strong>in</strong> the <strong>asbestos</strong> work area• the provision and locations of decontam<strong>in</strong>ation/chang<strong>in</strong>g facilities andnegative pressure exhaust units• the precautions that must be implemented to prevent the spread of <strong>asbestos</strong>contam<strong>in</strong>ation outside the <strong>asbestos</strong> removal area• air quality with<strong>in</strong> the enclosure (eg there must always be sufficient oxygenand mach<strong>in</strong>ery emitt<strong>in</strong>g any fumes or potentially dangerous gases needsto be placed outside the enclosure well away from any air <strong>in</strong>take for theenclosure)• the temperature with<strong>in</strong> the enclosure (especially to avoid heat stress)• any other hazards <strong>in</strong> the enclosure (these must be identified and the riskscontrolled before any <strong>asbestos</strong> removal work commences).322. Work methods may also need to be adapted for the work environment with<strong>in</strong>the enclosure. For example, rest breaks need to be based on a risk assessmenttak<strong>in</strong>g <strong>in</strong>to account factors such as the weather and heat<strong>in</strong>g/cool<strong>in</strong>grequirements.323. Heavy-duty plastic sheet<strong>in</strong>g (200 micron m<strong>in</strong>imum thickness) needs tobe used for the enclosure. Re-milled plastic sheet<strong>in</strong>g should not be used.324. Every location where the <strong>asbestos</strong> work area connects either to the outsideenvironment or to the rest of the build<strong>in</strong>g (eg w<strong>in</strong>dows, ducts, wall cavities,conduits and lift entrances) needs to be enclosed so that an airtight sealis ma<strong>in</strong>ta<strong>in</strong>ed for the duration of the <strong>asbestos</strong> removal work.325. The plastic sheet<strong>in</strong>g needs to enclose all the walls, w<strong>in</strong>dows and doors.Wooden cleats may be able to be used to anchor the plastic sheet<strong>in</strong>g to walls.326. View<strong>in</strong>g panels need to be placed <strong>in</strong> appropriate locations so that the workarea can be seen from outside the enclosure.327. Adequate light<strong>in</strong>g needs to be provided with<strong>in</strong> the enclosure, either:• naturally, us<strong>in</strong>g clear plastic or perspex panels <strong>in</strong> the enclosure walls, or• artificially, preferably from outside the enclosure us<strong>in</strong>g clear plastic orperspex panels (lights with<strong>in</strong> an enclosure can <strong>in</strong>crease the temperaturewith<strong>in</strong> the enclosure).328. All non-movable items (eg fixtures and fitt<strong>in</strong>gs) need to be covered with plasticsheet<strong>in</strong>g and all the jo<strong>in</strong>ts sealed.329. All movable items need to be removed from the <strong>asbestos</strong> removal area. If thisis not possible, they need to be moved to a convenient location and coveredwith two layers of plastic sheet<strong>in</strong>g with a m<strong>in</strong>imum overlap of 300mm betweenthe layers. Both layers need to be double taped.330. Airlocks need to be provided at the entry po<strong>in</strong>ts to the change area. Theyneed to be constructed us<strong>in</strong>g double sets of overlapp<strong>in</strong>g plastic with suitableprovisions for ensur<strong>in</strong>g a seal.56 <strong>Compliance</strong> code / <strong>Remov<strong>in</strong>g</strong> <strong>asbestos</strong> <strong>in</strong> <strong>workplaces</strong> <strong>WorkSafe</strong> <strong>Victoria</strong>