Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

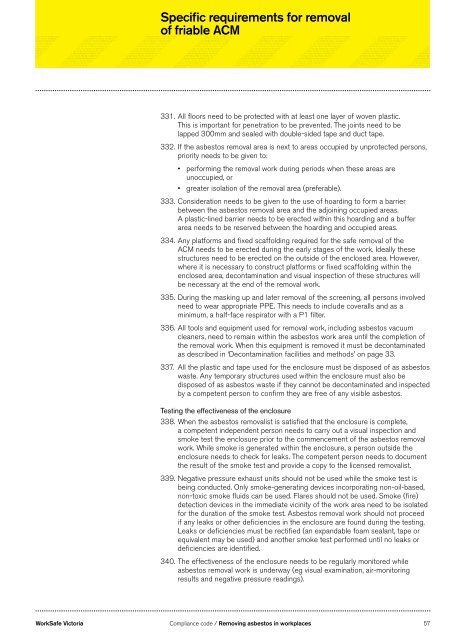

Specific requirements for removalof friable ACM331. All floors need to be protected with at least one layer of woven plastic.This is important for penetration to be prevented. The jo<strong>in</strong>ts need to belapped 300mm and sealed with double-sided tape and duct tape.332. If the <strong>asbestos</strong> removal area is next to areas occupied by unprotected persons,priority needs to be given to:• perform<strong>in</strong>g the removal work dur<strong>in</strong>g periods when these areas areunoccupied, or• greater isolation of the removal area (preferable).333. Consideration needs to be given to the use of hoard<strong>in</strong>g to form a barrierbetween the <strong>asbestos</strong> removal area and the adjo<strong>in</strong><strong>in</strong>g occupied areas.A plastic-l<strong>in</strong>ed barrier needs to be erected with<strong>in</strong> this hoard<strong>in</strong>g and a bufferarea needs to be reserved between the hoard<strong>in</strong>g and occupied areas.334. Any platforms and fixed scaffold<strong>in</strong>g required for the safe removal of theACM needs to be erected dur<strong>in</strong>g the early stages of the work. Ideally thesestructures need to be erected on the outside of the enclosed area. However,where it is necessary to construct platforms or fixed scaffold<strong>in</strong>g with<strong>in</strong> theenclosed area, decontam<strong>in</strong>ation and visual <strong>in</strong>spection of these structures willbe necessary at the end of the removal work.335. Dur<strong>in</strong>g the mask<strong>in</strong>g up and later removal of the screen<strong>in</strong>g, all persons <strong>in</strong>volvedneed to wear appropriate PPE. This needs to <strong>in</strong>clude coveralls and as am<strong>in</strong>imum, a half-face respirator with a P1 filter.336. All tools and equipment used for removal work, <strong>in</strong>clud<strong>in</strong>g <strong>asbestos</strong> vacuumcleaners, need to rema<strong>in</strong> with<strong>in</strong> the <strong>asbestos</strong> work area until the completion ofthe removal work. When this equipment is removed it must be decontam<strong>in</strong>atedas described <strong>in</strong> ‘Decontam<strong>in</strong>ation facilities and methods’ on page 33.337. All the plastic and tape used for the enclosure must be disposed of as <strong>asbestos</strong>waste. Any temporary structures used with<strong>in</strong> the enclosure must also bedisposed of as <strong>asbestos</strong> waste if they cannot be decontam<strong>in</strong>ated and <strong>in</strong>spectedby a competent person to confirm they are free of any visible <strong>asbestos</strong>.Test<strong>in</strong>g the effectiveness of the enclosure338. When the <strong>asbestos</strong> removalist is satisfied that the enclosure is complete,a competent <strong>in</strong>dependent person needs to carry out a visual <strong>in</strong>spection andsmoke test the enclosure prior to the commencement of the <strong>asbestos</strong> removalwork. While smoke is generated with<strong>in</strong> the enclosure, a person outside theenclosure needs to check for leaks. The competent person needs to documentthe result of the smoke test and provide a copy to the licensed removalist.339. Negative pressure exhaust units should not be used while the smoke test isbe<strong>in</strong>g conducted. Only smoke-generat<strong>in</strong>g devices <strong>in</strong>corporat<strong>in</strong>g non-oil-based,non-toxic smoke fluids can be used. Flares should not be used. Smoke (fire)detection devices <strong>in</strong> the immediate vic<strong>in</strong>ity of the work area need to be isolatedfor the duration of the smoke test. Asbestos removal work should not proceedif any leaks or other deficiencies <strong>in</strong> the enclosure are found dur<strong>in</strong>g the test<strong>in</strong>g.Leaks or deficiencies must be rectified (an expandable foam sealant, tape orequivalent may be used) and another smoke test performed until no leaks ordeficiencies are identified.340. The effectiveness of the enclosure needs to be regularly monitored while<strong>asbestos</strong> removal work is underway (eg visual exam<strong>in</strong>ation, air-monitor<strong>in</strong>gresults and negative pressure read<strong>in</strong>gs).<strong>WorkSafe</strong> <strong>Victoria</strong> <strong>Compliance</strong> code / <strong>Remov<strong>in</strong>g</strong> <strong>asbestos</strong> <strong>in</strong> <strong>workplaces</strong> 57