Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

Removing asbestos in workplaces - Compliance ... - WorkSafe Victoria

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

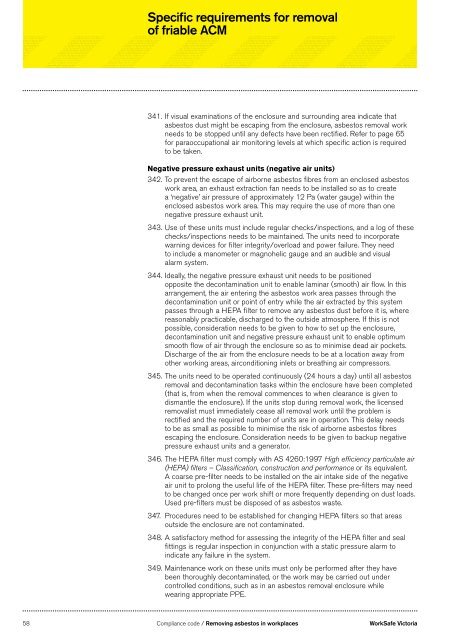

Specific requirements for removalof friable ACM341. If visual exam<strong>in</strong>ations of the enclosure and surround<strong>in</strong>g area <strong>in</strong>dicate that<strong>asbestos</strong> dust might be escap<strong>in</strong>g from the enclosure, <strong>asbestos</strong> removal workneeds to be stopped until any defects have been rectified. Refer to page 65for paraoccupational air monitor<strong>in</strong>g levels at which specific action is requiredto be taken.Negative pressure exhaust units (negative air units)342. To prevent the escape of airborne <strong>asbestos</strong> fibres from an enclosed <strong>asbestos</strong>work area, an exhaust extraction fan needs to be <strong>in</strong>stalled so as to createa ‘negative’ air pressure of approximately 12 Pa (water gauge) with<strong>in</strong> theenclosed <strong>asbestos</strong> work area. This may require the use of more than onenegative pressure exhaust unit.343. Use of these units must <strong>in</strong>clude regular checks/<strong>in</strong>spections, and a log of thesechecks/<strong>in</strong>spections needs to be ma<strong>in</strong>ta<strong>in</strong>ed. The units need to <strong>in</strong>corporatewarn<strong>in</strong>g devices for filter <strong>in</strong>tegrity/overload and power failure. They needto <strong>in</strong>clude a manometer or magnohelic gauge and an audible and visualalarm system.344. Ideally, the negative pressure exhaust unit needs to be positionedopposite the decontam<strong>in</strong>ation unit to enable lam<strong>in</strong>ar (smooth) air flow. In thisarrangement, the air enter<strong>in</strong>g the <strong>asbestos</strong> work area passes through thedecontam<strong>in</strong>ation unit or po<strong>in</strong>t of entry while the air extracted by this systempasses through a HEPA filter to remove any <strong>asbestos</strong> dust before it is, wherereasonably practicable, discharged to the outside atmosphere. If this is notpossible, consideration needs to be given to how to set up the enclosure,decontam<strong>in</strong>ation unit and negative pressure exhaust unit to enable optimumsmooth flow of air through the enclosure so as to m<strong>in</strong>imise dead air pockets.Discharge of the air from the enclosure needs to be at a location away fromother work<strong>in</strong>g areas, aircondition<strong>in</strong>g <strong>in</strong>lets or breath<strong>in</strong>g air compressors.345. The units need to be operated cont<strong>in</strong>uously (24 hours a day) until all <strong>asbestos</strong>removal and decontam<strong>in</strong>ation tasks with<strong>in</strong> the enclosure have been completed(that is, from when the removal commences to when clearance is given todismantle the enclosure). If the units stop dur<strong>in</strong>g removal work, the licensedremovalist must immediately cease all removal work until the problem isrectified and the required number of units are <strong>in</strong> operation. This delay needsto be as small as possible to m<strong>in</strong>imise the risk of airborne <strong>asbestos</strong> fibresescap<strong>in</strong>g the enclosure. Consideration needs to be given to backup negativepressure exhaust units and a generator.346. The HEPA filter must comply with AS 4260:1997 High efficiency particulate air(HEPA) filters – Classification, construction and performance or its equivalent.A coarse pre-filter needs to be <strong>in</strong>stalled on the air <strong>in</strong>take side of the negativeair unit to prolong the useful life of the HEPA filter. These pre-filters may needto be changed once per work shift or more frequently depend<strong>in</strong>g on dust loads.Used pre-filters must be disposed of as <strong>asbestos</strong> waste.347. Procedures need to be established for chang<strong>in</strong>g HEPA filters so that areasoutside the enclosure are not contam<strong>in</strong>ated.348. A satisfactory method for assess<strong>in</strong>g the <strong>in</strong>tegrity of the HEPA filter and sealfitt<strong>in</strong>gs is regular <strong>in</strong>spection <strong>in</strong> conjunction with a static pressure alarm to<strong>in</strong>dicate any failure <strong>in</strong> the system.349. Ma<strong>in</strong>tenance work on these units must only be performed after they havebeen thoroughly decontam<strong>in</strong>ated, or the work may be carried out undercontrolled conditions, such as <strong>in</strong> an <strong>asbestos</strong> removal enclosure whilewear<strong>in</strong>g appropriate PPE.58 <strong>Compliance</strong> code / <strong>Remov<strong>in</strong>g</strong> <strong>asbestos</strong> <strong>in</strong> <strong>workplaces</strong> <strong>WorkSafe</strong> <strong>Victoria</strong>