2009 MAGNETIC SYSTEMSMagnetic properties of ErCo x Mn 1−x O 3 perovskitesA spin reversal ph<strong>en</strong>om<strong>en</strong>on in perovskite manganitesABO 3 may appear wh<strong>en</strong> the rare-earth elem<strong>en</strong>t, having alarge magnetic mom<strong>en</strong>t (e.g. Gd, Er), interacts with theMn 3+ -Mn 4+ sublattice. This has be<strong>en</strong> found in manganitespartially substituted at the A-site by alkaline earth elem<strong>en</strong>ts.B-site substitutions also drastically modify the physicochemicalproperties of these materials, since for each dival<strong>en</strong>ttransition metal introduced in the lattice, a Mn 3+ ionwill transform into Mn 4+ . If the substitute is Co, the solidsolution may ext<strong>en</strong>d over a large range of conc<strong>en</strong>trationssince cobalt may adopt a 2+ and a 3+ oxidation states, dep<strong>en</strong>dingon the synthesis conditions. In these materials, thetotal magnetization changes its sign wh<strong>en</strong> field-cooled dueto a negative polarization of the rare-earth mom<strong>en</strong>t in thepres<strong>en</strong>ce of the internal field created by the ordered manganesesublattice [Peña et al., J. Magn. Magn. Mater. 310,159 (2007)].The isothermal magnetization shows two interesting features:(i) an intersection of the decreasing and increasingbranches of the magnetization loop at low fields, related tothe spin reversal <strong>des</strong>cribed above; (ii) a step-like increase athigh fields wh<strong>en</strong> the applied magnetic field increases [Peñaet al., J. Magn. Magn. Mater. 312, 78 (2007)]. Thesetwo anomalies have be<strong>en</strong> observed only in the Er-Co-basedsystem, for materials close to the ErCo 0.50 Mn 0.50 O 3 composition(figure 134).Figure 135: High field magnetization for ErCo x Mn 1−x O 3 samplesnormalized for the value at 15 T.Important results were obtained: (a) the high field transitionshifts towards higher applied fields wh<strong>en</strong> temperaturedecreases; (b) the high field transition shifts towards higherapplied fields wh<strong>en</strong> the Co/Mn conc<strong>en</strong>tration changes fromthe particular 50/50 ratio; (c) the magnetization does notsaturate at the highest applied field, but the ferromagneticloop <strong>en</strong>ds up at about 10 T; (d) no abrupt jumps are observedfor temperatures above 3 K; (e) magnetic relaxationis observed just before the transition occurs (figure 136).Magnetization loop for the ErCo 0.50 Mn 0.50 O 3 com-Figure 134:position.Figure 136: Magnetization as a function of time forErCo 0.50 Mn 0.50 O 3 . Insert: fit to a logarithmic behaviour.Furthermore, the high-field transition is of a dynamical naturesince both its amplitude and position dep<strong>en</strong>d on thesweep-rate of the applied-field. To get a deeper insight ofthis anomaly, high-field magnetization measurem<strong>en</strong>ts wereperformed at 4 K. (figure 135).Based on these results, several sc<strong>en</strong>arios are possible, suchas, dynamical movem<strong>en</strong>ts of domain walls, magnetic relaxationof ferromagnetic clusters, metamagnetic-like interactionsbetwe<strong>en</strong> Er 3+ and Co 2+ -Mn 4+ mom<strong>en</strong>ts.A. B. AntunesO. Peña (Sci<strong>en</strong>ces Chimiques de R<strong>en</strong>nes, Université de R<strong>en</strong>nes 1, R<strong>en</strong>nes, France), C. Moure (Electrocerámicas, Institutode Cerámica y Vidrio, CSIC, Madrid, Spain), S. de Brion (Institut Néel, Gr<strong>en</strong>oble, France)93

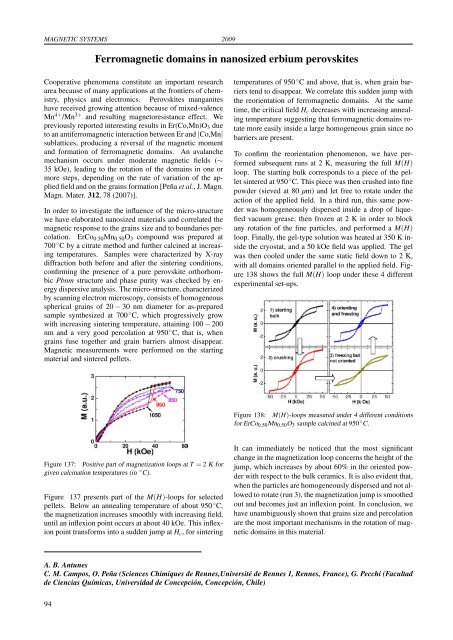

MAGNETIC SYSTEMS 2009Ferromagnetic domains in nanosized erbium perovskitesCooperative ph<strong>en</strong>om<strong>en</strong>a constitute an important researcharea because of many applications at the frontiers of chemistry,physics and electronics. Perovskites manganiteshave received growing att<strong>en</strong>tion because of mixed-val<strong>en</strong>ceMn 4+ /Mn 3+ and resulting magnetoresistance effect. Wepreviously reported interesting results in Er(Co,Mn)O 3 dueto an antiferromagnetic interaction betwe<strong>en</strong> Er and |Co,Mn|sublattices, producing a reversal of the magnetic mom<strong>en</strong>tand formation of ferromagnetic domains. An avalanchemechanism occurs under moderate magnetic fields (∼35 kOe), leading to the rotation of the domains in one ormore steps, dep<strong>en</strong>ding on the rate of variation of the appliedfield and on the grains formation [Peña et al., J. Magn.Magn. Mater. 312, 78 (2007)].In order to investigate the influ<strong>en</strong>ce of the micro-structurewe have elaborated nanosized materials and correlated themagnetic response to the grains size and to boundaries percolation.ErCo 0.50 Mn 0.50 O 3 compound was prepared at700 ◦ C by a citrate method and further calcined at increasingtemperatures. Samples were characterized by X-raydiffraction both before and after the sintering conditions,confirming the pres<strong>en</strong>ce of a pure perovskite orthorhombicPbnm structure and phase purity was checked by <strong>en</strong>ergydispersive analysis. The micro-structure, characterizedby scanning electron microscopy, consists of homog<strong>en</strong>eousspherical grains of 20 − 30 nm diameter for as-preparedsample synthesized at 700 ◦ C, which progressively growwith increasing sintering temperature, attaining 100 − 200nm and a very good percolation at 950 ◦ C, that is, wh<strong>en</strong>grains fuse together and grain barriers almost disappear.Magnetic measurem<strong>en</strong>ts were performed on the startingmaterial and sintered pellets.temperatures of 950 ◦ C and above, that is, wh<strong>en</strong> grain barrierst<strong>en</strong>d to disappear. We correlate this sudd<strong>en</strong> jump withthe reori<strong>en</strong>tation of ferromagnetic domains. At the sametime, the critical field H c decreases with increasing annealingtemperature suggesting that ferromagnetic domains rotatemore easily inside a large homog<strong>en</strong>eous grain since nobarriers are pres<strong>en</strong>t.To confirm the reori<strong>en</strong>tation ph<strong>en</strong>om<strong>en</strong>on, we have performedsubsequ<strong>en</strong>t runs at 2 K, measuring the full M(H)loop. The starting bulk corresponds to a piece of the pelletsintered at 950 ◦ C. This piece was th<strong>en</strong> crushed into finepowder (sieved at 80 µm) and let free to rotate under theaction of the applied field. In a third run, this same powderwas homog<strong>en</strong>eously dispersed inside a drop of liquefiedvacuum grease, th<strong>en</strong> froz<strong>en</strong> at 2 K in order to blockany rotation of the fine particles, and performed a M(H)loop. Finally, the gel-type solution was heated at 350 K insidethe cryostat, and a 50 kOe field was applied. The gelwas th<strong>en</strong> cooled under the same static field down to 2 K,with all domains ori<strong>en</strong>ted parallel to the applied field. Figure138 shows the full M(H) loop under these 4 differ<strong>en</strong>texperim<strong>en</strong>tal set-ups.Figure 138: M(H)-loops measured under 4 differ<strong>en</strong>t conditionsfor ErCo 0.50 Mn 0.50 O 3 sample calcined at 950 ◦ C.Figure 137: Positive part of magnetization loops at T = 2 K forgiv<strong>en</strong> calcination temperatures (in ◦ C).Figure 137 pres<strong>en</strong>ts part of the M(H)-loops for selectedpellets. Below an annealing temperature of about 950 ◦ C,the magnetization increases smoothly with increasing field,until an inflexion point occurs at about 40 kOe. This inflexionpoint transforms into a sudd<strong>en</strong> jump at H c , for sinteringIt can immediately be noticed that the most significantchange in the magnetization loop concerns the height of thejump, which increases by about 60% in the ori<strong>en</strong>ted powderwith respect to the bulk ceramics. It is also evid<strong>en</strong>t that,wh<strong>en</strong> the particles are homog<strong>en</strong>eously dispersed and not allowedto rotate (run 3), the magnetization jump is smoothedout and becomes just an inflexion point. In conclusion, wehave unambiguously shown that grains size and percolationare the most important mechanisms in the rotation of magneticdomains in this material.A. B. AntunesC. M. Campos, O. Peña (Sci<strong>en</strong>ces Chimiques de R<strong>en</strong>nes,Université de R<strong>en</strong>nes 1, R<strong>en</strong>nes, France), G. Pecchi (Facultadde Ci<strong>en</strong>cias Químicas, Universidad de Concepción, Concepción, Chile)94

- Page 1 and 2:

LABORATOIRE NATIONAL DES CHAMPS MAG

- Page 4 and 5:

TABLE OF CONTENTSPreface 1Carbon Al

- Page 6 and 7:

Coexistence of closed orbit and qua

- Page 8:

2009PrefaceDear Reader,You have bef

- Page 12 and 13:

2009 CARBON ALLOTROPESInvestigation

- Page 14 and 15:

2009 CARBON ALLOTROPESPropagative L

- Page 16 and 17:

2009 CARBON ALLOTROPESEdge fingerpr

- Page 18 and 19:

2009 CARBON ALLOTROPESObservation o

- Page 20 and 21:

2009 CARBON ALLOTROPESImproving gra

- Page 22 and 23:

2009 CARBON ALLOTROPESHow perfect c

- Page 24 and 25:

2009 CARBON ALLOTROPESTuning the el

- Page 26 and 27:

2009 CARBON ALLOTROPESElectric fiel

- Page 28 and 29:

2009 CARBON ALLOTROPESMagnetotransp

- Page 30 and 31:

2009 CARBON ALLOTROPESGraphite from

- Page 32:

2009Two-Dimensional Electron Gas25

- Page 35 and 36:

TWO-DIMENSIONAL ELECTRON GAS 2009Di

- Page 37 and 38:

TWO-DIMENSIONAL ELECTRON GAS 2009Sp

- Page 39 and 40:

TWO-DIMENSIONAL ELECTRON GAS 2009Cr

- Page 41 and 42:

TWO-DIMENSIONAL ELECTRON GAS 2009Re

- Page 43 and 44:

TWO-DIMENSIONAL ELECTRON GAS 2009In

- Page 45 and 46:

TWO-DIMENSIONAL ELECTRON GAS 2009Ho

- Page 47 and 48:

TWO-DIMENSIONAL ELECTRON GAS 2009Te

- Page 50 and 51: 2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 52 and 53: 2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 54 and 55: 2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 56 and 57: 2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 58 and 59: 2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 60: 2009Metals, Superconductors and Str

- Page 63 and 64: METALS, SUPERCONDUCTORS... 2009Anom

- Page 65 and 66: METALS, SUPERCONDUCTORS... 2009Magn

- Page 67 and 68: METALS, SUPERCONDUCTORS ... 2009Coe

- Page 69 and 70: METALS, SUPERCONDUCTORS ... 2009Fie

- Page 71 and 72: METALS, SUPERCONDUCTORS... 2009High

- Page 73 and 74: METALS, SUPERCONDUCTORS... 2009Angu

- Page 75 and 76: METALS, SUPERCONDUCTORS... 2009Magn

- Page 77 and 78: METALS, SUPERCONDUCTORS... 2009Meta

- Page 79 and 80: METALS, SUPERCONDUCTORS... 2009Temp

- Page 81 and 82: METALS, SUPERCONDUCTORS... 200974

- Page 84 and 85: 2009 MAGNETIC SYSTEMSY b 3+ → Er

- Page 86 and 87: 2009 MAGNETIC SYSTEMSMagnetotranspo

- Page 88 and 89: 2009 MAGNETIC SYSTEMSHigh field tor

- Page 90 and 91: 2009 MAGNETIC SYSTEMSNuclear magnet

- Page 92 and 93: 2009 MAGNETIC SYSTEMSStructural ana

- Page 94 and 95: 2009 MAGNETIC SYSTEMSEnhancement ma

- Page 96 and 97: 2009 MAGNETIC SYSTEMSInvestigation

- Page 98 and 99: 2009 MAGNETIC SYSTEMSField-induced

- Page 102: 2009Biology, Chemistry and Soft Mat

- Page 105 and 106: BIOLOGY, CHEMISTRY AND SOFT MATTER

- Page 108 and 109: 2009 APPLIED SUPERCONDUCTIVITYMagne

- Page 110 and 111: 2009 APPLIED SUPERCONDUCTIVITYPhtha

- Page 112: 2009Magneto-Science105

- Page 115 and 116: MAGNETO-SCIENCE 2009Study of the in

- Page 117 and 118: MAGNETO-SCIENCE 2009Magnetohydrodyn

- Page 119 and 120: MAGNETO-SCIENCE 2009112

- Page 122 and 123: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 124 and 125: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 126 and 127: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 128 and 129: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 130 and 131: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 132 and 133: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 134 and 135: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 136 and 137: 2009 PROPOSALSProposals for Magnet

- Page 138 and 139: 2009 PROPOSALSSpin-Jahn-Teller effe

- Page 140 and 141: 2009 PROPOSALSQuantum Oscillations

- Page 142 and 143: 2009 PROPOSALSThermoelectric tensor

- Page 144 and 145: 2009 PROPOSALSDr. EscoffierCyclotro

- Page 146 and 147: 2009 PROPOSALSHigh field magnetotra

- Page 148 and 149: 2009 THESESPhD Theses 20091. Nanot

- Page 150 and 151:

2009 PUBLICATIONS[21] O. Drachenko,

- Page 152 and 153:

2009 PUBLICATIONS[75] S. Nowak, T.

- Page 154 and 155:

Contributors of the LNCMI to the Pr

- Page 156 and 157:

Institut Jean Lamour, Nancy : 68Ins

- Page 158 and 159:

Lawrence Berkeley National Laborato