2009 MAGNET DEVELOPMENT AND INSTRUMENTATIONTowards developing a high T c superconducting magnetHigh critical temperature superconductors (HTS) op<strong>en</strong> extremelyinteresting perspectives for high field applicationssuch as high field magnets for NMR, SMES or physicalinvestigations [J. Schwartz et al., IEEE trans. on Appl. Superc.,18,pp. 70, (2008)]. The demand is high for 25, 30 andev<strong>en</strong> 50 T magnets and is beyond the possibilities offeredby low critical temperature superconductors, for exampleNb 3 Sn. The superconducting solutions for very high fieldsmeet the requirem<strong>en</strong>ts for sustainable developm<strong>en</strong>t.Rutherford cable. These data show that the wires withstandthe cabling process and that they are magnetically isotropic.It will be possible to test the HTS magnets in liquid/gascooling or conduction cooling.Rec<strong>en</strong>tly, the interest for Bi-2212 round wire has be<strong>en</strong> reinforcedfor high field applications [Sh<strong>en</strong> et al., Appl. Phys.Lett. 95, 152516, (2009)] These wires show very high performancein terms of critical curr<strong>en</strong>ts at ultra high fields,at least on short samples. The main issue with Bi-2212 remainsthe heat treatm<strong>en</strong>t, which should be very preciselycontrolled. The melting temperature plays a crucial part andshould be within a window of one or two degrees to obtainthe required highest critical curr<strong>en</strong>ts d<strong>en</strong>sities. Ev<strong>en</strong> morerec<strong>en</strong>tly, the second g<strong>en</strong>eration (2G) HTS conductors, theYBaCuO coated conductors, show also very exciting performancesin terms of curr<strong>en</strong>t capacities under very highfields whereas their mechanical properties are excell<strong>en</strong>t forthe IBAD route. The mechanical performance is of greatimportance for very high field magnets. Substantial advanceshave be<strong>en</strong> achieved with the 2G HTS and they hav<strong>en</strong>ow reached a stage, in terms of l<strong>en</strong>gths, where it is possibleto use them in real devices.Several laboratories in Gr<strong>en</strong>oble (IN, LNCMI, CRETA andG2Elab) have begun works on HTS magnets. IN andG2Elab have built and successfully tested an importantHTS magnet (800 kJ) operating at 20 K in the context of aDGA project. The pres<strong>en</strong>t works are carried out in the contextof a European Project ”EuCARD” and an ANR project”SUPER-SMES”. The purpose is to study the most suitableHTS materials and develop the technology for veryhigh field and high performance HTS magnets for SMES(storage) or high <strong>en</strong>ergy physics (magnets for accelerators)purposes. An id<strong>en</strong>tified issue with HTS magnets is theirprotection and studies have begun both from simulation andexperim<strong>en</strong>tal points of view. In the developm<strong>en</strong>t program,the critical characteristics remain the fundam<strong>en</strong>tal data required.Advanced characterization tools have be<strong>en</strong> developed,in particular to obtain the critical characteristic underhigh fields at variable temperatures and variable field ori<strong>en</strong>tations.After delicate adjustm<strong>en</strong>ts, the system works perfectly.Figure 174 shows the sample holder and the newcryostat under construction to test HTS coils at variabletemperatures in two LNCMI high field magnets. Figure 175shows two PIT Bi-2212 short samples round wires criticalcharacteristics. These wires are extracted from a NexansFigure 174: Sample holder and variable temperature cryostat.Figure 175: Bi-2212 I c (B) performance for round wires.F. Debray, J. P. Domps, E. Mossang, S. DufresnesP. Brosse-Maron, J. P. Leggeri (Institute Neel, Gr<strong>en</strong>oble), J. M. Rey (CEA, IRFU, Saclay), P. Tixador (INP, Gr<strong>en</strong>oble)123

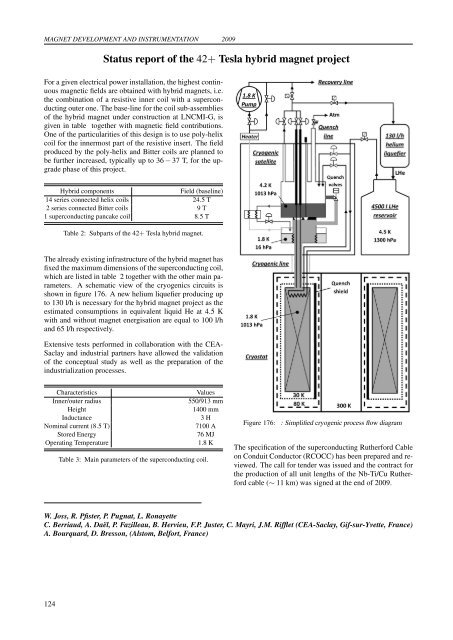

MAGNET DEVELOPMENT AND INSTRUMENTATION 2009Status report of the 42+ Tesla hybrid magnet projectFor a giv<strong>en</strong> electrical power installation, the highest continuousmagnetic fields are obtained with hybrid magnets, i.e.the combination of a resistive inner coil with a superconductingouter one. The base-line for the coil sub-assembliesof the hybrid magnet under construction at LNCMI-G, isgiv<strong>en</strong> in table together with magnetic field contributions.One of the particularities of this <strong>des</strong>ign is to use poly-helixcoil for the innermost part of the resistive insert. The fieldproduced by the poly-helix and Bitter coils are planned tobe further increased, typically up to 36 − 37 T, for the upgradephase of this project.Hybrid compon<strong>en</strong>tsField (baseline)14 series connected helix coils 24.5 T2 series connected Bitter coils 9 T1 superconducting pancake coil 8.5 TTable 2: Subparts of the 42+ Tesla hybrid magnet.The already existing infrastructure of the hybrid magnet hasfixed the maximum dim<strong>en</strong>sions of the superconducting coil,which are listed in table 2 together with the other main parameters.A schematic view of the cryog<strong>en</strong>ics circuits isshown in figure 176. A new helium liquefier producing upto 130 l/h is necessary for the hybrid magnet project as theestimated consumptions in equival<strong>en</strong>t liquid He at 4.5 Kwith and without magnet <strong>en</strong>ergisation are equal to 100 l/hand 65 l/h respectively.Ext<strong>en</strong>sive tests performed in collaboration with the CEA-Saclay and industrial partners have allowed the validationof the conceptual study as well as the preparation of theindustrialization processes.CharacteristicsValuesInner/outer radius550/913 mmHeight1400 mmInductance3 HNominal curr<strong>en</strong>t (8.5 T)7100 AStored Energy76 MJOperating Temperature1.8 KTable 3: Main parameters of the superconducting coil.Figure 176:: Simplified cryog<strong>en</strong>ic process flow diagramThe specification of the superconducting Rutherford Cableon Conduit Conductor (RCOCC) has be<strong>en</strong> prepared and reviewed.The call for t<strong>en</strong>der was issued and the contract forthe production of all unit l<strong>en</strong>gths of the Nb-Ti/Cu Rutherfordcable (∼ 11 km) was signed at the <strong>en</strong>d of 2009.W. Joss, R. Pfister, P. Pugnat, L. RonayetteC. Berriaud, A. Daël, P. Fazilleau, B. Hervieu, F.P. Juster, C. Mayri, J.M. Rifflet (CEA-Saclay, Gif-sur-Yvette, France)A. Bourquard, D. Bresson, (Alstom, Belfort, France)124

- Page 1 and 2:

LABORATOIRE NATIONAL DES CHAMPS MAG

- Page 4 and 5:

TABLE OF CONTENTSPreface 1Carbon Al

- Page 6 and 7:

Coexistence of closed orbit and qua

- Page 8:

2009PrefaceDear Reader,You have bef

- Page 12 and 13:

2009 CARBON ALLOTROPESInvestigation

- Page 14 and 15:

2009 CARBON ALLOTROPESPropagative L

- Page 16 and 17:

2009 CARBON ALLOTROPESEdge fingerpr

- Page 18 and 19:

2009 CARBON ALLOTROPESObservation o

- Page 20 and 21:

2009 CARBON ALLOTROPESImproving gra

- Page 22 and 23:

2009 CARBON ALLOTROPESHow perfect c

- Page 24 and 25:

2009 CARBON ALLOTROPESTuning the el

- Page 26 and 27:

2009 CARBON ALLOTROPESElectric fiel

- Page 28 and 29:

2009 CARBON ALLOTROPESMagnetotransp

- Page 30 and 31:

2009 CARBON ALLOTROPESGraphite from

- Page 32:

2009Two-Dimensional Electron Gas25

- Page 35 and 36:

TWO-DIMENSIONAL ELECTRON GAS 2009Di

- Page 37 and 38:

TWO-DIMENSIONAL ELECTRON GAS 2009Sp

- Page 39 and 40:

TWO-DIMENSIONAL ELECTRON GAS 2009Cr

- Page 41 and 42:

TWO-DIMENSIONAL ELECTRON GAS 2009Re

- Page 43 and 44:

TWO-DIMENSIONAL ELECTRON GAS 2009In

- Page 45 and 46:

TWO-DIMENSIONAL ELECTRON GAS 2009Ho

- Page 47 and 48:

TWO-DIMENSIONAL ELECTRON GAS 2009Te

- Page 50 and 51:

2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 52 and 53:

2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 54 and 55:

2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 56 and 57:

2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 58 and 59:

2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 60:

2009Metals, Superconductors and Str

- Page 63 and 64:

METALS, SUPERCONDUCTORS... 2009Anom

- Page 65 and 66:

METALS, SUPERCONDUCTORS... 2009Magn

- Page 67 and 68:

METALS, SUPERCONDUCTORS ... 2009Coe

- Page 69 and 70:

METALS, SUPERCONDUCTORS ... 2009Fie

- Page 71 and 72:

METALS, SUPERCONDUCTORS... 2009High

- Page 73 and 74:

METALS, SUPERCONDUCTORS... 2009Angu

- Page 75 and 76:

METALS, SUPERCONDUCTORS... 2009Magn

- Page 77 and 78:

METALS, SUPERCONDUCTORS... 2009Meta

- Page 79 and 80: METALS, SUPERCONDUCTORS... 2009Temp

- Page 81 and 82: METALS, SUPERCONDUCTORS... 200974

- Page 84 and 85: 2009 MAGNETIC SYSTEMSY b 3+ → Er

- Page 86 and 87: 2009 MAGNETIC SYSTEMSMagnetotranspo

- Page 88 and 89: 2009 MAGNETIC SYSTEMSHigh field tor

- Page 90 and 91: 2009 MAGNETIC SYSTEMSNuclear magnet

- Page 92 and 93: 2009 MAGNETIC SYSTEMSStructural ana

- Page 94 and 95: 2009 MAGNETIC SYSTEMSEnhancement ma

- Page 96 and 97: 2009 MAGNETIC SYSTEMSInvestigation

- Page 98 and 99: 2009 MAGNETIC SYSTEMSField-induced

- Page 100 and 101: 2009 MAGNETIC SYSTEMSMagnetic prope

- Page 102: 2009Biology, Chemistry and Soft Mat

- Page 105 and 106: BIOLOGY, CHEMISTRY AND SOFT MATTER

- Page 108 and 109: 2009 APPLIED SUPERCONDUCTIVITYMagne

- Page 110 and 111: 2009 APPLIED SUPERCONDUCTIVITYPhtha

- Page 112: 2009Magneto-Science105

- Page 115 and 116: MAGNETO-SCIENCE 2009Study of the in

- Page 117 and 118: MAGNETO-SCIENCE 2009Magnetohydrodyn

- Page 119 and 120: MAGNETO-SCIENCE 2009112

- Page 122 and 123: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 124 and 125: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 126 and 127: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 128 and 129: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 132 and 133: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 134 and 135: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 136 and 137: 2009 PROPOSALSProposals for Magnet

- Page 138 and 139: 2009 PROPOSALSSpin-Jahn-Teller effe

- Page 140 and 141: 2009 PROPOSALSQuantum Oscillations

- Page 142 and 143: 2009 PROPOSALSThermoelectric tensor

- Page 144 and 145: 2009 PROPOSALSDr. EscoffierCyclotro

- Page 146 and 147: 2009 PROPOSALSHigh field magnetotra

- Page 148 and 149: 2009 THESESPhD Theses 20091. Nanot

- Page 150 and 151: 2009 PUBLICATIONS[21] O. Drachenko,

- Page 152 and 153: 2009 PUBLICATIONS[75] S. Nowak, T.

- Page 154 and 155: Contributors of the LNCMI to the Pr

- Page 156 and 157: Institut Jean Lamour, Nancy : 68Ins

- Page 158 and 159: Lawrence Berkeley National Laborato