2009 APPLIED SUPERCONDUCTIVITYMagnetic field behaviour of ex-situ processed MgB 2 multifilam<strong>en</strong>tary wiresIn order to make MgB 2 useful not only for dc but also for acapplications further conductor developm<strong>en</strong>t and optimizationare still needed, in particular to reduce the ac lossescaused by magnetic hysteresis in the MgB 2 core, filam<strong>en</strong>tcoupling and eddy curr<strong>en</strong>ts flowing through the metallicmatrix. In this context research work should be focused onmultifilam<strong>en</strong>tary strands with a large number of very finefilam<strong>en</strong>ts, twisted filam<strong>en</strong>ts and non-magnetic and high resistivitysheath.We have focused our work on obtaining multifilam<strong>en</strong>taryconductors with a large number of very fine filam<strong>en</strong>ts. Inthis context, the powder’s granulometry can play a crucialrole. In this experim<strong>en</strong>t we have prepared two MgB 2 startingpowders which are either not milled (NM) or milled(M) with differ<strong>en</strong>t granulometries (NM= 1.5 µm and M=450 nm) and by the ex-situ powder in tube (PIT) methodwe have realized multifilam<strong>en</strong>tary wires with 19, 91 and361 filam<strong>en</strong>ts and an average size of each filam<strong>en</strong>t of 279,110 and 30 µm respectively. In figure 143 the cross sectionsof the three wire types are shown.We have studied the relationship betwe<strong>en</strong> grain and filam<strong>en</strong>tsize in terms of transport properties. The measuredcritical curr<strong>en</strong>t d<strong>en</strong>sities (J C ) for the samples with NM powderand M powder are reported in figure 144. The criticalcurr<strong>en</strong>t d<strong>en</strong>sity improves with milling for all samples asreported in our previous work [A. Malagoli et al J. Appl.Phys. 104, 103908 (2008)]. Focusing on the behaviour ofthe not milled samples, passing from 19 to 91 filam<strong>en</strong>ts aremarkable critical curr<strong>en</strong>t d<strong>en</strong>sity degradation is evid<strong>en</strong>t,that is partially recovered going to 361 filam<strong>en</strong>ts. On thecontrary for the milled samples 19M and 91M have almostid<strong>en</strong>tical critical curr<strong>en</strong>t d<strong>en</strong>sity - a slightly better behaviourin field being observed in 91M. Wh<strong>en</strong> the number of filam<strong>en</strong>tsincreases up to 361, critical curr<strong>en</strong>t d<strong>en</strong>sity decreasesstaying though above the 361NM.Such a behaviour of the critical curr<strong>en</strong>t d<strong>en</strong>sity in field cannotbe explained or well understood simply considering theeffects of milling. In these complex conductors several factorshave to be tak<strong>en</strong> into account which have an effect onthe transport properties: the starting granulometry of theMgB 2 powders, the cold deformation force and the final filam<strong>en</strong>tsize. Therefore, in the final analysis, the capabilityof these conductors to transport high critical curr<strong>en</strong>ts cruciallydep<strong>en</strong>ds on a proper balance of these parameters. Inthis work we have obtained the best ratio filam<strong>en</strong>t size/grainsize on a 91 filam<strong>en</strong>ts wire with an average filam<strong>en</strong>t size ofabout 110 µm and a powder starting average grain diameterof about 450 nm. A finer MgB 2 granulometry seems to b<strong>en</strong>eeded to realize very thin filam<strong>en</strong>ts (10−30 µm) with highcritical curr<strong>en</strong>t d<strong>en</strong>sity.Figure 143: Images of differ<strong>en</strong>t cross sections through the wireswith 19, 91 and 361 filam<strong>en</strong>ts respectively.Figure 144: Transport critical curr<strong>en</strong>t d<strong>en</strong>sity (J C ) for differ<strong>en</strong>tmilled (M) and not milled (NM) samples measured up to magneticfields of 13 T using a wide bore resistive magnet and a Heliumbath cryostat (T = 4.2 K).E. MossangA. Malagoli, G. Romano, M. Vignolo, C. Ferdeghini, M. Putti (CNR-INFM LAMIA, G<strong>en</strong>ova, Italy), S. Brisigotti, G.Grasso, A. Tumino (Columbus Superconductors S.p.A., G<strong>en</strong>ova, Italy)101

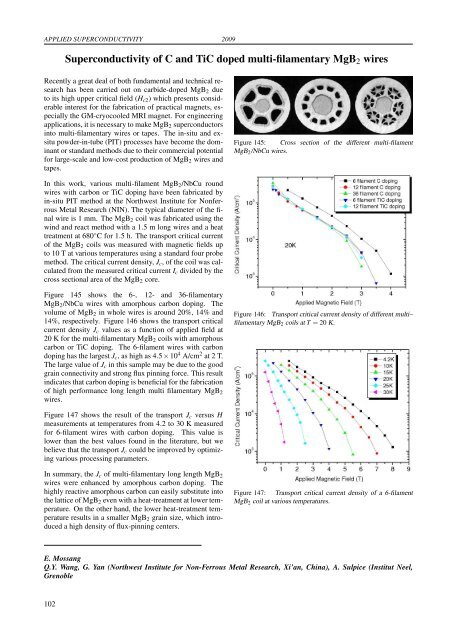

APPLIED SUPERCONDUCTIVITY 2009Superconductivity of C and TiC doped multi-filam<strong>en</strong>tary MgB 2 wiresRec<strong>en</strong>tly a great deal of both fundam<strong>en</strong>tal and technical researchhas be<strong>en</strong> carried out on carbide-doped MgB 2 dueto its high upper critical field (H c2 ) which pres<strong>en</strong>ts considerableinterest for the fabrication of practical magnets, especiallythe GM-cryocooled MRI magnet. For <strong>en</strong>gineeringapplications, it is necessary to make MgB 2 superconductorsinto multi-filam<strong>en</strong>tary wires or tapes. The in-situ and exsitupowder-in-tube (PIT) processes have become the dominantor standard methods due to their commercial pot<strong>en</strong>tialfor large-scale and low-cost production of MgB 2 wires andtapes.Figure 145: Cross section of the differ<strong>en</strong>t multi-filam<strong>en</strong>tMgB 2 /NbCu wires.In this work, various multi-filam<strong>en</strong>t MgB 2 /NbCu roundwires with carbon or TiC doping have be<strong>en</strong> fabricated byin-situ PIT method at the Northwest Institute for NonferrousMetal Research (NIN). The typical diameter of the finalwire is 1 mm. The MgB 2 coil was fabricated using thewind and react method with a 1.5 m long wires and a heattreatm<strong>en</strong>t at 680 ◦ C for 1.5 h. The transport critical curr<strong>en</strong>tof the MgB 2 coils was measured with magnetic fields upto 10 T at various temperatures using a standard four probemethod. The critical curr<strong>en</strong>t d<strong>en</strong>sity, J c , of the coil was calculatedfrom the measured critical curr<strong>en</strong>t I c divided by thecross sectional area of the MgB 2 core.Figure 145 shows the 6-, 12- and 36-filam<strong>en</strong>taryMgB 2 /NbCu wires with amorphous carbon doping. Thevolume of MgB 2 in whole wires is around 20%, 14% and14%, respectively. Figure 146 shows the transport criticalcurr<strong>en</strong>t d<strong>en</strong>sity J c values as a function of applied field at20 K for the multi-filam<strong>en</strong>tary MgB 2 coils with amorphouscarbon or TiC doping. The 6-filam<strong>en</strong>t wires with carbondoping has the largest J c , as high as 4.5×10 4 A/cm 2 at 2 T.The large value of J c in this sample may be due to the goodgrain connectivity and strong flux pinning force. This resultindicates that carbon doping is b<strong>en</strong>eficial for the fabricationof high performance long l<strong>en</strong>gth multi filam<strong>en</strong>tary MgB 2wires.Figure 146: Transport critical curr<strong>en</strong>t d<strong>en</strong>sity of differ<strong>en</strong>t multi–filam<strong>en</strong>tary MgB 2 coils at T = 20 K.Figure 147 shows the result of the transport J c versus Hmeasurem<strong>en</strong>ts at temperatures from 4.2 to 30 K measuredfor 6-filam<strong>en</strong>t wires with carbon doping. This value islower than the best values found in the literature, but webelieve that the transport J c could be improved by optimizingvarious processing parameters.In summary, the J c of multi-filam<strong>en</strong>tary long l<strong>en</strong>gth MgB 2wires were <strong>en</strong>hanced by amorphous carbon doping. Thehighly reactive amorphous carbon can easily substitute intothe lattice of MgB 2 ev<strong>en</strong> with a heat-treatm<strong>en</strong>t at lower temperature.On the other hand, the lower heat-treatm<strong>en</strong>t temperatureresults in a smaller MgB 2 grain size, which introduceda high d<strong>en</strong>sity of flux-pinning c<strong>en</strong>ters.Figure 147: Transport critical curr<strong>en</strong>t d<strong>en</strong>sity of a 6-filam<strong>en</strong>tMgB 2 coil at various temperatures.E. MossangQ.Y. Wang, G. Yan (Northwest Institute for Non-Ferrous Metal Research, Xi’an, China), A. Sulpice (Institut Neel,Gr<strong>en</strong>oble102

- Page 1 and 2:

LABORATOIRE NATIONAL DES CHAMPS MAG

- Page 4 and 5:

TABLE OF CONTENTSPreface 1Carbon Al

- Page 6 and 7:

Coexistence of closed orbit and qua

- Page 8:

2009PrefaceDear Reader,You have bef

- Page 12 and 13:

2009 CARBON ALLOTROPESInvestigation

- Page 14 and 15:

2009 CARBON ALLOTROPESPropagative L

- Page 16 and 17:

2009 CARBON ALLOTROPESEdge fingerpr

- Page 18 and 19:

2009 CARBON ALLOTROPESObservation o

- Page 20 and 21:

2009 CARBON ALLOTROPESImproving gra

- Page 22 and 23:

2009 CARBON ALLOTROPESHow perfect c

- Page 24 and 25:

2009 CARBON ALLOTROPESTuning the el

- Page 26 and 27:

2009 CARBON ALLOTROPESElectric fiel

- Page 28 and 29:

2009 CARBON ALLOTROPESMagnetotransp

- Page 30 and 31:

2009 CARBON ALLOTROPESGraphite from

- Page 32:

2009Two-Dimensional Electron Gas25

- Page 35 and 36:

TWO-DIMENSIONAL ELECTRON GAS 2009Di

- Page 37 and 38:

TWO-DIMENSIONAL ELECTRON GAS 2009Sp

- Page 39 and 40:

TWO-DIMENSIONAL ELECTRON GAS 2009Cr

- Page 41 and 42:

TWO-DIMENSIONAL ELECTRON GAS 2009Re

- Page 43 and 44:

TWO-DIMENSIONAL ELECTRON GAS 2009In

- Page 45 and 46:

TWO-DIMENSIONAL ELECTRON GAS 2009Ho

- Page 47 and 48:

TWO-DIMENSIONAL ELECTRON GAS 2009Te

- Page 50 and 51:

2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 52 and 53:

2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 54 and 55:

2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 56 and 57: 2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 58 and 59: 2009 SEMICONDUCTORS AND NANOSTRUCTU

- Page 60: 2009Metals, Superconductors and Str

- Page 63 and 64: METALS, SUPERCONDUCTORS... 2009Anom

- Page 65 and 66: METALS, SUPERCONDUCTORS... 2009Magn

- Page 67 and 68: METALS, SUPERCONDUCTORS ... 2009Coe

- Page 69 and 70: METALS, SUPERCONDUCTORS ... 2009Fie

- Page 71 and 72: METALS, SUPERCONDUCTORS... 2009High

- Page 73 and 74: METALS, SUPERCONDUCTORS... 2009Angu

- Page 75 and 76: METALS, SUPERCONDUCTORS... 2009Magn

- Page 77 and 78: METALS, SUPERCONDUCTORS... 2009Meta

- Page 79 and 80: METALS, SUPERCONDUCTORS... 2009Temp

- Page 81 and 82: METALS, SUPERCONDUCTORS... 200974

- Page 84 and 85: 2009 MAGNETIC SYSTEMSY b 3+ → Er

- Page 86 and 87: 2009 MAGNETIC SYSTEMSMagnetotranspo

- Page 88 and 89: 2009 MAGNETIC SYSTEMSHigh field tor

- Page 90 and 91: 2009 MAGNETIC SYSTEMSNuclear magnet

- Page 92 and 93: 2009 MAGNETIC SYSTEMSStructural ana

- Page 94 and 95: 2009 MAGNETIC SYSTEMSEnhancement ma

- Page 96 and 97: 2009 MAGNETIC SYSTEMSInvestigation

- Page 98 and 99: 2009 MAGNETIC SYSTEMSField-induced

- Page 100 and 101: 2009 MAGNETIC SYSTEMSMagnetic prope

- Page 102: 2009Biology, Chemistry and Soft Mat

- Page 105 and 106: BIOLOGY, CHEMISTRY AND SOFT MATTER

- Page 110 and 111: 2009 APPLIED SUPERCONDUCTIVITYPhtha

- Page 112: 2009Magneto-Science105

- Page 115 and 116: MAGNETO-SCIENCE 2009Study of the in

- Page 117 and 118: MAGNETO-SCIENCE 2009Magnetohydrodyn

- Page 119 and 120: MAGNETO-SCIENCE 2009112

- Page 122 and 123: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 124 and 125: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 126 and 127: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 128 and 129: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 130 and 131: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 132 and 133: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 134 and 135: 2009 MAGNET DEVELOPMENT AND INSTRUM

- Page 136 and 137: 2009 PROPOSALSProposals for Magnet

- Page 138 and 139: 2009 PROPOSALSSpin-Jahn-Teller effe

- Page 140 and 141: 2009 PROPOSALSQuantum Oscillations

- Page 142 and 143: 2009 PROPOSALSThermoelectric tensor

- Page 144 and 145: 2009 PROPOSALSDr. EscoffierCyclotro

- Page 146 and 147: 2009 PROPOSALSHigh field magnetotra

- Page 148 and 149: 2009 THESESPhD Theses 20091. Nanot

- Page 150 and 151: 2009 PUBLICATIONS[21] O. Drachenko,

- Page 152 and 153: 2009 PUBLICATIONS[75] S. Nowak, T.

- Page 154 and 155: Contributors of the LNCMI to the Pr

- Page 156 and 157: Institut Jean Lamour, Nancy : 68Ins

- Page 158 and 159:

Lawrence Berkeley National Laborato