Mise en page 1 - Laboratoire National des Champs Magnétiques ...

Mise en page 1 - Laboratoire National des Champs Magnétiques ...

Mise en page 1 - Laboratoire National des Champs Magnétiques ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

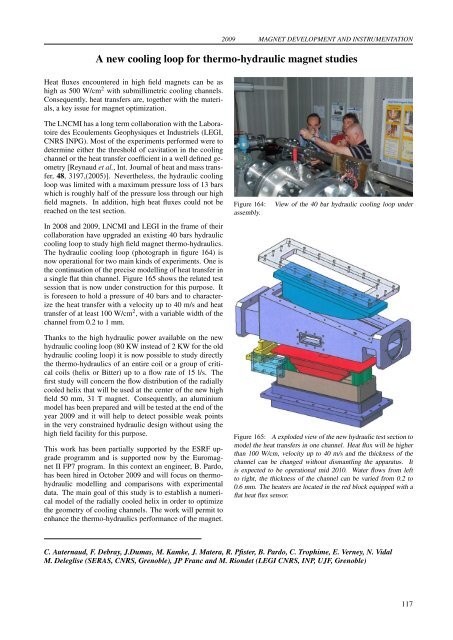

2009 MAGNET DEVELOPMENT AND INSTRUMENTATIONA new cooling loop for thermo-hydraulic magnet studiesHeat fluxes <strong>en</strong>countered in high field magnets can be ashigh as 500 W/cm 2 with submillimetric cooling channels.Consequ<strong>en</strong>tly, heat transfers are, together with the materials,a key issue for magnet optimization.The LNCMI has a long term collaboration with the <strong>Laboratoire</strong><strong>des</strong> Ecoulem<strong>en</strong>ts Geophysiques et Industriels (LEGI,CNRS INPG). Most of the experim<strong>en</strong>ts performed were todetermine either the threshold of cavitation in the coolingchannel or the heat transfer coeffici<strong>en</strong>t in a well defined geometry[Reynaud et al., Int. Journal of heat and mass transfer,48, 3197,(2005)]. Nevertheless, the hydraulic coolingloop was limited with a maximum pressure loss of 13 barswhich is roughly half of the pressure loss through our highfield magnets. In addition, high heat fluxes could not bereached on the test section.In 2008 and 2009, LNCMI and LEGI in the frame of theircollaboration have upgraded an existing 40 bars hydrauliccooling loop to study high field magnet thermo-hydraulics.The hydraulic cooling loop (photograph in figure 164) isnow operational for two main kinds of experim<strong>en</strong>ts. One isthe continuation of the precise modelling of heat transfer ina single flat thin channel. Figure 165 shows the related testsession that is now under construction for this purpose. Itis forese<strong>en</strong> to hold a pressure of 40 bars and to characterizethe heat transfer with a velocity up to 40 m/s and heattransfer of at least 100 W/cm 2 , with a variable width of thechannel from 0.2 to 1 mm.Figure 164:assembly.View of the 40 bar hydraulic cooling loop underThanks to the high hydraulic power available on the newhydraulic cooling loop (80 KW instead of 2 KW for the oldhydraulic cooling loop) it is now possible to study directlythe thermo-hydraulics of an <strong>en</strong>tire coil or a group of criticalcoils (helix or Bitter) up to a flow rate of 15 l/s. Thefirst study will concern the flow distribution of the radiallycooled helix that will be used at the c<strong>en</strong>ter of the new highfield 50 mm, 31 T magnet. Consequ<strong>en</strong>tly, an aluminiummodel has be<strong>en</strong> prepared and will be tested at the <strong>en</strong>d of theyear 2009 and it will help to detect possible weak pointsin the very constrained hydraulic <strong>des</strong>ign without using thehigh field facility for this purpose.This work has be<strong>en</strong> partially supported by the ESRF upgradeprogramm and is supported now by the EuromagnetII FP7 program. In this context an <strong>en</strong>gineer, B. Pardo,has be<strong>en</strong> hired in October 2009 and will focus on thermohydraulicmodelling and comparisons with experim<strong>en</strong>taldata. The main goal of this study is to establish a numericalmodel of the radially cooled helix in order to optimizethe geometry of cooling channels. The work will permit to<strong>en</strong>hance the thermo-hydraulics performance of the magnet.Figure 165: A exploded view of the new hydraulic test section tomodel the heat transfers in one channel. Heat flux will be higherthan 100 W/cm, velocity up to 40 m/s and the thickness of thechannel can be changed without dismantling the apparatus. Itis expected to be operational mid 2010. Water flows from leftto right, the thickness of the channel can be varied from 0.2 to0.6 mm. The heaters are located in the red block equipped with aflat heat flux s<strong>en</strong>sor.C. Auternaud, F. Debray, J.Dumas, M. Kamke, J. Matera, R. Pfister, B. Pardo, C. Trophime, E. Verney, N. VidalM. Deleglise (SERAS, CNRS, Gr<strong>en</strong>oble), JP Franc and M. Riondet (LEGI CNRS, INP, UJF, Gr<strong>en</strong>oble)117