Mise en page 1 - Laboratoire National des Champs Magnétiques ...

Mise en page 1 - Laboratoire National des Champs Magnétiques ...

Mise en page 1 - Laboratoire National des Champs Magnétiques ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

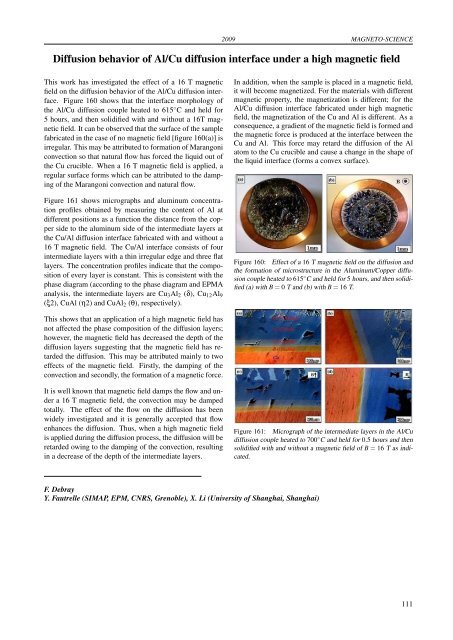

2009 MAGNETO-SCIENCEDiffusion behavior of Al/Cu diffusion interface under a high magnetic fieldThis work has investigated the effect of a 16 T magneticfield on the diffusion behavior of the Al/Cu diffusion interface.Figure 160 shows that the interface morphology ofthe Al/Cu diffusion couple heated to 615 ◦ C and held for5 hours, and th<strong>en</strong> solidified with and without a 16T magneticfield. It can be observed that the surface of the samplefabricated in the case of no magnetic field [figure 160(a)] isirregular. This may be attributed to formation of Marangoniconvection so that natural flow has forced the liquid out ofthe Cu crucible. Wh<strong>en</strong> a 16 T magnetic field is applied, aregular surface forms which can be attributed to the dampingof the Marangoni convection and natural flow.Figure 161 shows micrographs and aluminum conc<strong>en</strong>trationprofiles obtained by measuring the cont<strong>en</strong>t of Al atdiffer<strong>en</strong>t positions as a function the distance from the copperside to the aluminum side of the intermediate layers atthe Cu/Al diffusion interface fabricated with and without a16 T magnetic field. The Cu/Al interface consists of fourintermediate layers with a thin irregular edge and three flatlayers. The conc<strong>en</strong>tration profiles indicate that the compositionof every layer is constant. This is consist<strong>en</strong>t with thephase diagram (according to the phase diagram and EPMAanalysis, the intermediate layers are Cu 3 Al 2 (δ), Cu 12 Al 9(ξ2), CuAl (η2) and CuAl 2 (θ), respectively).In addition, wh<strong>en</strong> the sample is placed in a magnetic field,it will become magnetized. For the materials with differ<strong>en</strong>tmagnetic property, the magnetization is differ<strong>en</strong>t; for theAl/Cu diffusion interface fabricated under high magneticfield, the magnetization of the Cu and Al is differ<strong>en</strong>t. As aconsequ<strong>en</strong>ce, a gradi<strong>en</strong>t of the magnetic field is formed andthe magnetic force is produced at the interface betwe<strong>en</strong> theCu and Al. This force may retard the diffusion of the Alatom to the Cu crucible and cause a change in the shape ofthe liquid interface (forms a convex surface).Figure 160: Effect of a 16 T magnetic field on the diffusion andthe formation of microstructure in the Aluminum/Copper diffusioncouple heated to 615 ◦ C and held for 5 hours, and th<strong>en</strong> solidified(a) with B = 0 T and (b) with B = 16 T.This shows that an application of a high magnetic field hasnot affected the phase composition of the diffusion layers;however, the magnetic field has decreased the depth of thediffusion layers suggesting that the magnetic field has retardedthe diffusion. This may be attributed mainly to twoeffects of the magnetic field. Firstly, the damping of theconvection and secondly, the formation of a magnetic force.It is well known that magnetic field damps the flow and undera 16 T magnetic field, the convection may be dampedtotally. The effect of the flow on the diffusion has be<strong>en</strong>widely investigated and it is g<strong>en</strong>erally accepted that flow<strong>en</strong>hances the diffusion. Thus, wh<strong>en</strong> a high magnetic fieldis applied during the diffusion process, the diffusion will beretarded owing to the damping of the convection, resultingin a decrease of the depth of the intermediate layers.Figure 161: Micrograph of the intermediate layers in the Al/Cudiffusion couple heated to 700 ◦ C and held for 0.5 hours and th<strong>en</strong>solidified with and without a magnetic field of B = 16 T as indicated.F. DebrayY. Fautrelle (SIMAP, EPM, CNRS, Gr<strong>en</strong>oble), X. Li (University of Shanghai, Shanghai)111