- Page 1 and 2:

Fluid Control SystemsSelected produ

- Page 3 and 4:

Your personal copy of the newBürke

- Page 6 and 7:

Experience you can rely onBürkert

- Page 8:

Solenoid valvesA uniquecomprehensiv

- Page 11 and 12:

Customised solutions are our added

- Page 13 and 14:

Control Valve - request for quotati

- Page 15 and 16:

➔the comprehensive automation sol

- Page 18 and 19:

16Mass Flow Controller and Mass Flo

- Page 21 and 22:

01Solenoid Valves19

- Page 23 and 24:

212/2 and 3/2-way solenoid valvesFo

- Page 25 and 26:

232/2 and 3/2-way solenoid valvesFo

- Page 27 and 28:

25Dimensions [mm]Bottom viewPort co

- Page 29 and 30:

27Solenoid Valves 6011Subject to mo

- Page 31 and 32:

29Dimensions [mm]Port Body Coil Coi

- Page 33 and 34:

31 Solenoid ValvesOrdering chart fo

- Page 35 and 36:

108.5 (with G1/2)105 (with G1/4)33D

- Page 37 and 38:

35Solenoid Valves 0255Subject to mo

- Page 39 and 40:

37Body A and BDimensions [mm]Body B

- Page 41 and 42:

39Solenoid Valves 0256Subject to mo

- Page 43 and 44:

41Dimensions [mm]Version A B CThrea

- Page 45 and 46:

43Valve versionMax. operating press

- Page 47 and 48:

45Dimensions [mm]Possible connectio

- Page 49 and 50:

47Possible connectionsCircuit funct

- Page 51 and 52:

49Ordering chart for valves (other

- Page 53 and 54:

51Possible connectionsCircuit funct

- Page 55 and 56:

53Ordering chart for flange valve m

- Page 57 and 58:

55Dimensions [mm]Ordering chart for

- Page 59 and 60:

57Dimensions [mm]The ports marked w

- Page 61 and 62:

59Dimensions [mm]Body materialD B E

- Page 63 and 64:

61Dimensions [mm]DN A D (spigot con

- Page 65 and 66:

63Dimensions [mm]DN [mm] G A B C D

- Page 67 and 68:

65Dimensions [mm]Threaded portDN D

- Page 69 and 70:

67Ordering chart for valves (other

- Page 71 and 72:

69Dimensions [mm]G Thread AC coil D

- Page 73 and 74:

71Solenoid Valves 6213Subject to mo

- Page 75 and 76:

73Dimensions [mm]DN [mm] G B C D F

- Page 77 and 78:

75Dimensions [mm] according to DIN

- Page 79 and 80:

77Delivered as circuit function ACh

- Page 81 and 82:

79Solenoid Valves 5282Subject to mo

- Page 83 and 84:

81Dimensions [mm]All versions PVC-b

- Page 85 and 86:

83Dimensions [mm]DN D B E F L20 NPT

- Page 87 and 88:

85Dimensions [mm]DN D B E F H J13 N

- Page 89 and 90:

87Dimensions [mm]DN D B E F H J13 N

- Page 91 and 92:

89Dimensions [mm]DN A B D H L R8 46

- Page 93:

91Dimensions [mm]DN A B D H L R8.0

- Page 96 and 97:

94Overview of Process Valves and Co

- Page 98 and 99:

96Control Heads for pneumatically o

- Page 100 and 101:

98Selection guide for Process Valve

- Page 102 and 103: 100Selection guide sorted by applic

- Page 104 and 105: 1022/2-way Angle-Seat Valvefor medi

- Page 106 and 107: 104Flow direction below seatProcess

- Page 108 and 109: 1063/2-way Angle-Seat Valve, compac

- Page 110 and 111: 108Process Valves 2002Ordering char

- Page 112 and 113: 1102/2-way Globe Valvefor media up

- Page 114 and 115: 112Dimensions [mm]2012With flange c

- Page 116 and 117: 114Ordering chart for valves with f

- Page 118 and 119: 116Ordering chart for valves with f

- Page 120 and 121: 1182/2-way Diaphragm Valve with pla

- Page 122 and 123: 120Ordering chart for DN 15-50 valv

- Page 124 and 125: 1222/2-way Diaphragm Valve, stainle

- Page 126 and 127: 124Ordering chart for valvesFlange

- Page 128 and 129: 1262/2-way Diaphragm Valve, forged

- Page 130 and 131: 128Process Valves 2031 ForgedOrderi

- Page 132 and 133: 1302-way Diaphragm Valve, with plas

- Page 134 and 135: 1322-way Diaphragm Valve, with cold

- Page 136 and 137: 134Ordering chart (other versions o

- Page 138 and 139: 1362-way Diaphragm Valve, forged st

- Page 140 and 141: 138Process Valves 3233 ForgedOrderi

- Page 142 and 143: 140Zero Deadleg T Valve, pneumatica

- Page 144 and 145: 142Tank Bottom Valve,pneumatically

- Page 146 and 147: 144Zero Deadleg T-Valve, ManuallyOp

- Page 148 and 149: 146Tank Bottom Valve, Manually Oper

- Page 150 and 151: 148Electric Rotary Actuator forQuar

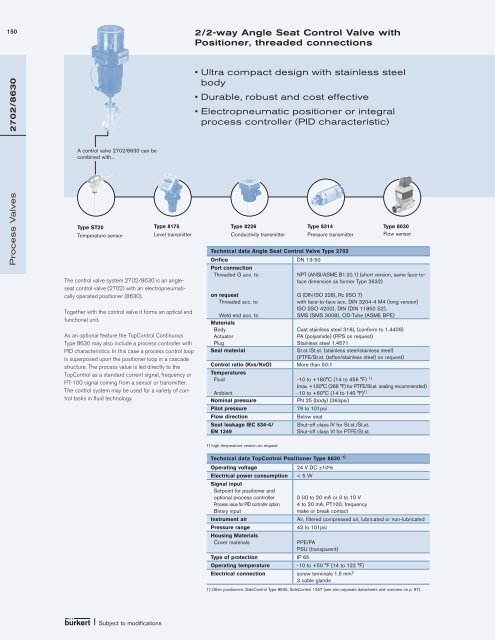

- Page 154 and 155: 1522/2-way Globe Control Valve• N

- Page 156 and 157: 154Diaphragm Control Valve, forged

- Page 158 and 159: 156

- Page 160 and 161: 158Overview of Process Pneumatics C

- Page 162 and 163: 160Selection guide for Process Pneu

- Page 164 and 165: 162Selection guide for Process Pneu

- Page 166 and 167: 1642/2-way Miniature Solenoid Valve

- Page 168 and 169: 16660115 ø7.2UNF 10-324.317M526141

- Page 170 and 171: 1682/2-way Compact Solenoid Valve

- Page 172 and 173: 170Ordering chart for valvesGeneral

- Page 174 and 175: 1723/2-way Miniature Solenoid Valve

- Page 176 and 177: 174Single manifoldAccessoryProcess

- Page 178 and 179: 1763/2-way Miniature Direct Mountin

- Page 180 and 181: 1783/2-way Miniature Solenoid Valve

- Page 182 and 183: 180Ordering chart for valvesValves

- Page 184 and 185: 1823/2-way Direct Mounting Pilot Va

- Page 186 and 187: 1843/2-way Miniature Rocker Solenoi

- Page 188 and 189: 186Ordering chart for single manifo

- Page 190 and 191: 1883/2-way Solenoid Valvesub-base c

- Page 192 and 193: 190Ordering chart for valves (other

- Page 194 and 195: 1922/2-way Solenoid Valvewith servo

- Page 196 and 197: 1943/2-way Solenoid Valvefor gases

- Page 198 and 199: 1962/2 or 3/2-way Solenoid Valvefor

- Page 200 and 201: 1983/2, 5/2 and 5/3-way Solenoid Va

- Page 202 and 203:

200Manifold assembly with pneumatic

- Page 204 and 205:

2025/2 and 3/2-way Solenoid Valvefo

- Page 206 and 207:

2044/2-way Solenoid Valvefor pneuma

- Page 208 and 209:

2063/2 and 4/2-way Solenoid Valvefo

- Page 210 and 211:

2083/2 and 4/2-way Solenoid Valvefo

- Page 212 and 213:

210Manifold assembly from pneumatic

- Page 214 and 215:

2123/2 and 4/2-way Solenoid Valvefo

- Page 216 and 217:

214Options for service portProcess

- Page 218 and 219:

2163/2 and 5/2-way Solenoid Valvefo

- Page 220 and 221:

218Ordering chart for Type MP12 pne

- Page 222 and 223:

220Modular pneumatic valve island

- Page 224 and 225:

222Remote Process Actuation Control

- Page 226 and 227:

224

- Page 228 and 229:

226Selection guide for Analytical V

- Page 230 and 231:

2282/2 and 3/2-way Flipper Solenoid

- Page 232 and 233:

230Dimensions of valves with tube h

- Page 234 and 235:

2322/2 and 3/2-way Rocker Solenoid

- Page 236 and 237:

234Dimensions [mm]Complete valves w

- Page 238 and 239:

2362/2 or 3/2-way Rocker Solenoid V

- Page 240 and 241:

2382/2 or 3/2-way Miniature RockerS

- Page 242 and 243:

2402/2 or 3/2-way Solenoid Valvefor

- Page 244 and 245:

2422/2 or 3/2-way Solenoid Valvefor

- Page 246 and 247:

244

- Page 248 and 249:

246Selection guide for Flow Control

- Page 250 and 251:

248Overview of Flow Control with Pa

- Page 252 and 253:

250Overview of Flow Control with Ba

- Page 254 and 255:

252Overview of Flow Control with Ma

- Page 256 and 257:

254Paddle-wheel sensor for low flow

- Page 258 and 259:

256INLINE flow sensor8030Type 8030

- Page 260 and 261:

258INLINE flow sensor - II 1 G/D•

- Page 262 and 263:

260Safety instructions - Notice of

- Page 264 and 265:

262INLINE flow switchwith On/Off in

- Page 266 and 267:

264INLINE flow transmitter• Flow

- Page 268 and 269:

266INLINE flow batch controller•

- Page 270 and 271:

268INLINE fitting with paddle-wheel

- Page 272 and 273:

FLOWFLOWFLOWFLOWFLOWFLOWFLOW270Pres

- Page 274 and 275:

272INLINE fitting dimensionsFlange

- Page 276 and 277:

274Positive Displacement Flow Trans

- Page 278 and 279:

276Ordering chart for fitting S070i

- Page 280 and 281:

278INSERTION flow sensor8020Type 80

- Page 282 and 283:

280INSERTION flow transmitter• 15

- Page 284 and 285:

282System versions - Panel-mounted

- Page 286 and 287:

284INSERTION batch controller• 15

- Page 288 and 289:

286System versions - Panel-mounted

- Page 290 and 291:

288Electromagnetic flow transmitter

- Page 292 and 293:

290Electromagnetic flow transmitter

- Page 294 and 295:

292INSERTION fittingfor flow measur

- Page 296 and 297:

H294Flow diagram: selection of fitt

- Page 298 and 299:

296Sensors S020Insertion fitting di

- Page 300 and 301:

298Ordering chart - Fitting S020S02

- Page 302 and 303:

300Full Bore Magflowmeter forContin

- Page 304 and 305:

302Dimensions [mm] Electronic Type

- Page 306 and 307:

304Selection guide for Level Contro

- Page 308 and 309:

306Selection guide for Pressure Con

- Page 310 and 311:

308Pressure Transmitter (2-wire) /

- Page 312 and 313:

310Pressure Transmitter• Ceramic

- Page 314 and 315:

312Pressure Transmitterfor general

- Page 316 and 317:

314Selection guide for Temperature

- Page 318 and 319:

316Screw-in Temperature Sensor / Sw

- Page 320 and 321:

318Selection guide for Analytical C

- Page 322 and 323:

320Overview of Analytical Control p

- Page 324 and 325:

322Digital pH Transmitter, Compact

- Page 326 and 327:

324Ordering chart for accessoriesSe

- Page 328 and 329:

326Digital O.R.P. Transmitter,compa

- Page 330 and 331:

328Ordering chart for accessoriesSe

- Page 332 and 333:

330Digital Conductivity Transmitter

- Page 334 and 335:

332Ordering chart for the Type 8225

- Page 336 and 337:

334Digital Inductive ConductivityTr

- Page 338 and 339:

336Ordering chart for accessoriesSe

- Page 340 and 341:

338INSERTION fittingfor analysis me

- Page 342 and 343:

340Sensors S020Dimensions [mm] oftr

- Page 344 and 345:

342Insertion fitting dimensionsTrue

- Page 346 and 347:

344Accessories: measuring chamber f

- Page 348 and 349:

346

- Page 350 and 351:

348Proportional ValvesProportional

- Page 352 and 353:

350Type selection diagram for Propo

- Page 354 and 355:

352Proportional Valves 2821/6022/23

- Page 356 and 357:

354Proportional Valve Low-∆p• C

- Page 358 and 359:

356Proportional Valvewith control e

- Page 360 and 361:

358Control Electronicsfor Proportio

- Page 362 and 363:

360Mass Flow Controller (MFC)for ga

- Page 364 and 365:

362

- Page 366 and 367:

364Selection guide for ControllersA

- Page 368 and 369:

366Digital Timer Unitwith 4 switch

- Page 370 and 371:

368Digital Timer unitwith 8 switch

- Page 372 and 373:

370Compact Plug-on Flow Controllerf

- Page 374 and 375:

372Compact Plug-on Flow PressureCon

- Page 376 and 377:

374Compact Temperature Controller

- Page 378 and 379:

376

- Page 380 and 381:

378Subject to modificationsApproval

- Page 382 and 383:

3802/2-way Compact General PurposeS

- Page 384 and 385:

3823/2-way Compact Solenoid Valvewi

- Page 386 and 387:

3842/2-way Solenoid Valvefor neutra

- Page 388 and 389:

3862/2-way Solenoid Valvewith servo

- Page 390 and 391:

388Ordering chart for valves (other

- Page 392 and 393:

3905/2 and 5/3-way Solenoid Valve f

- Page 394 and 395:

392Manifold assembly with Type MP07

- Page 396 and 397:

3945/2 and 3/2-way Solenoid Valve f

- Page 398 and 399:

3963/2-way I.S. Solenoid Valvefor p

- Page 400 and 401:

3985/2 and 5/3-way I.S. Solenoid Va

- Page 402 and 403:

4003/2 and 5/2-way I.S. Solenoid Va

- Page 404 and 405:

402

- Page 406 and 407:

404Cable Plug to DIN EN 175301-803,

- Page 408 and 409:

406Industry standard Cable Plug,For

- Page 410 and 411:

408Cable Plug to DIN EN 175301-803,

- Page 412 and 413:

410 Bürkert - your local business

- Page 415:

03/06 / © Burkert Contromatic Inc.