Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Synthesis of oxide-polymer nanocomposites via plasma<br />

polymerization<br />

Jens Suffner (1) , Gallus Schechner (2) , Hermann Sieger (1) , Horst Hahn (1),(3)<br />

(1) Joint Research Laboratory Nanomaterials<br />

(2) SusTech GmbH<br />

(3) Institute for Nanotechnology (FZ Karlsruhe)<br />

In the last years, nanoscale materials have gained tremendous interest in science<br />

due to their unique properties, like superparamagnetism, superplasticity, and<br />

quantum confinement.<br />

Nanoscale powders are characterized by a large surface-to-volume ratio leading to<br />

specific surface areas in the range of several h<strong>und</strong>reds of square meters per gram.<br />

Therefore it is obvious, that the particle-matrix interface has a large impact on the<br />

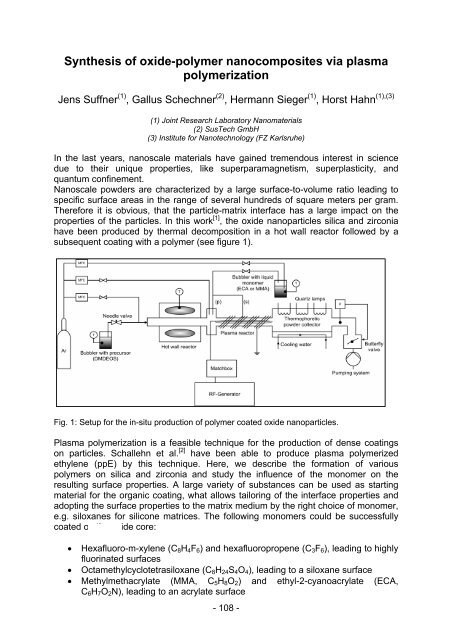

properties of the particles. In this work [1] , the oxide nanoparticles silica and zirconia<br />

have been produced by thermal decomposition in a hot wall reactor followed by a<br />

subsequent coating with a polymer (see figure 1).<br />

Fig. 1: Setup for the in-situ production of polymer coated oxide nanoparticles.<br />

Plasma polymerization is a feasible technique for the production of dense coatings<br />

on particles. Schallehn et al. [2] have been able to produce plasma polymerized<br />

ethylene (ppE) by this technique. Here, we describe the formation of various<br />

polymers on silica and zirconia and study the influence of the monomer on the<br />

resulting surface properties. A large variety of substances can be used as starting<br />

material for the organic coating, what allows tailoring of the interface properties and<br />

adopting the surface properties to the matrix medium by the right choice of monomer,<br />

e.g. siloxanes for silicone matrices. The following monomers could be successfully<br />

coated on the oxide core:<br />

• Hexafluoro-m-xylene (C8H4F6) and hexafluoropropene (C3F6), leading to highly<br />

fluorinated surfaces<br />

• Octamethylcyclotetrasiloxane (C8H24S4O4), leading to a siloxane surface<br />

• Methylmethacrylate (MMA, C5H8O2) and ethyl-2-cyanoacrylate (ECA,<br />

C6H7O2N), leading to an acrylate surface<br />

- 108 -