Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The glass transition temperature (Tg) of Cu50Zr50 and Cu47.5Zr47.5Al5 2 mm∅ rods are<br />

estimated to be 671 K and 698 K, respectively. The supercooled liquid region (∆Tx) for<br />

Cu50Zr50 and Cu47.5Zr47.5Al5 is 46 K and 74 K, respectively. This proves that addition of Al<br />

increases the glass-forming ability of binary Cu50Zr50. The resulting Cu47.5Zr47.5Al5 glass<br />

exhibits high strength (2265 MPa) together with a large room temperature ductility of up to<br />

18%, as depicted in Fig. 2. After yielding a strong increase in the flow stress is observed<br />

during deformation indicating a “work-hardening” like behavior.<br />

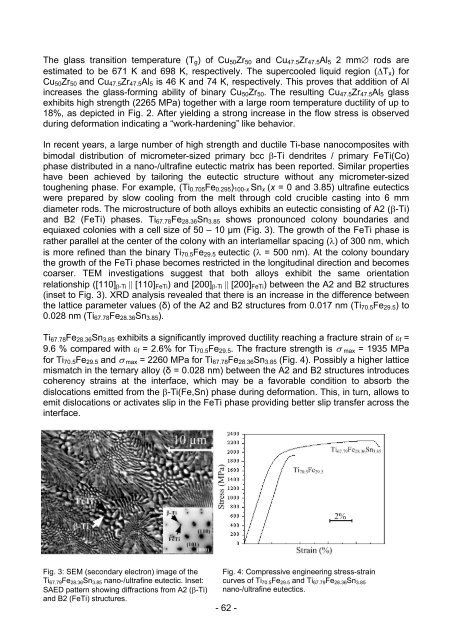

In recent years, a large number of high strength and ductile Ti-base nanocomposites with<br />

bimodal distribution of micrometer-sized primary bcc β-Ti dendrites / primary FeTi(Co)<br />

phase distributed in a nano-/ultrafine eutectic matrix has been reported. Similar properties<br />

have been achieved by tailoring the eutectic structure without any micrometer-sized<br />

toughening phase. For example, (Ti0.705Fe0.295)100-x Snx (x = 0 and 3.85) ultrafine eutectics<br />

were prepared by slow cooling from the melt through cold crucible casting into 6 mm<br />

diameter rods. The microstructure of both alloys exhibits an eutectic consisting of A2 (β-Ti)<br />

and B2 (FeTi) phases. Ti67.78Fe28.36Sn3.85 shows pronounced colony bo<strong>und</strong>aries and<br />

equiaxed colonies with a cell size of 50 – 10 µm (Fig. 3). The growth of the FeTi phase is<br />

rather parallel at the center of the colony with an interlamellar spacing (λ) of 300 nm, which<br />

is more refined than the binary Ti70.5Fe29.5 eutectic (λ = 500 nm). At the colony bo<strong>und</strong>ary<br />

the growth of the FeTi phase becomes restricted in the longitudinal direction and becomes<br />

coarser. TEM investigations suggest that both alloys exhibit the same orientation<br />

relationship ([110]β-Ti || [110]FeTi) and [200]β-Ti || [200]FeTi) between the A2 and B2 structures<br />

(inset to Fig. 3). XRD analysis revealed that there is an increase in the difference between<br />

the lattice parameter values (δ) of the A2 and B2 structures from 0.017 nm (Ti70.5Fe29.5) to<br />

0.028 nm (Ti67.78Fe28.36Sn3.85).<br />

Ti67.78Fe28.36Sn3.85 exhibits a significantly improved ductility reaching a fracture strain of εf =<br />

9.6 % compared with εf = 2.6% for Ti70.5Fe29.5. The fracture strength is σ max = 1935 MPa<br />

for Ti70.5Fe29.5 and σ max = 2260 MPa for Ti67.78Fe28.36Sn3.85 (Fig. 4). Possibly a higher lattice<br />

mismatch in the ternary alloy (δ = 0.028 nm) between the A2 and B2 structures introduces<br />

coherency strains at the interface, which may be a favorable condition to absorb the<br />

dislocations emitted from the β-Ti(Fe,Sn) phase during deformation. This, in turn, allows to<br />

emit dislocations or activates slip in the FeTi phase providing better slip transfer across the<br />

interface.<br />

Fig. 3: SEM (secondary electron) image of the<br />

Ti67.79Fe28.36Sn3.85 nano-/ultrafine eutectic. Inset:<br />

SAED pattern showing diffractions from A2 (β-Ti)<br />

and B2 (FeTi) structures.<br />

Fig. 4: Compressive engineering stress-strain<br />

curves of Ti70.5Fe29.5 and Ti67.79Fe28.36Sn3.85<br />

nano-/ultrafine eutectics.<br />

- 62 -