Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Alkyl- and aryl-modified Si(111) for silicon/organic hybrid devices<br />

Ralf Hunger, Wolfram Jaegermann<br />

Silicon/Organic junctions attract interest in several application perspectives: for<br />

silicon/organic hybrid devices such as biosensors, storage devices, or solar cells, as well<br />

as in the perspective of molecular electronics. It combines the advantages of modularity<br />

and tailoring capabilities of organic chemistry with the established, industrial-scale proven<br />

silicon technology.<br />

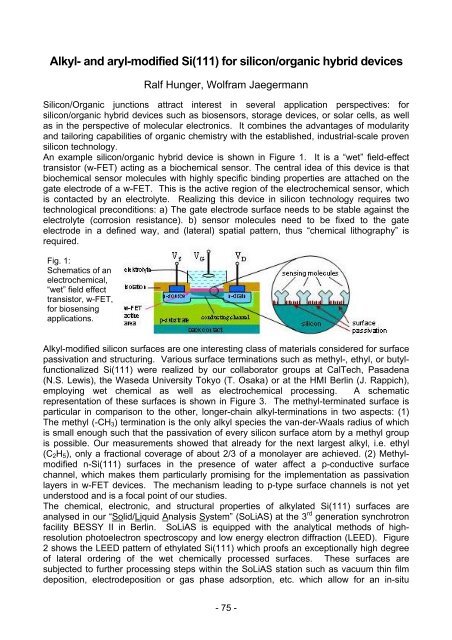

An example silicon/organic hybrid device is shown in Figure 1. It is a “wet” field-effect<br />

transistor (w-FET) acting as a biochemical sensor. The central idea of this device is that<br />

biochemical sensor molecules with highly specific binding properties are attached on the<br />

gate electrode of a w-FET. This is the active region of the electrochemical sensor, which<br />

is contacted by an electrolyte. Realizing this device in silicon technology requires two<br />

technological preconditions: a) The gate electrode surface needs to be stable against the<br />

electrolyte (corrosion resistance). b) sensor molecules need to be fixed to the gate<br />

electrode in a defined way, and (lateral) spatial pattern, thus “chemical lithography” is<br />

required.<br />

Fig. 1:<br />

Schematics of an<br />

electrochemical,<br />

“wet” field effect<br />

transistor, w-FET,<br />

for biosensing<br />

applications.<br />

Alkyl-modified silicon surfaces are one interesting class of materials considered for surface<br />

passivation and structuring. Various surface terminations such as methyl-, ethyl, or butylfunctionalized<br />

Si(111) were realized by our collaborator groups at CalTech, Pasadena<br />

(N.S. Lewis), the Waseda University Tokyo (T. Osaka) or at the HMI Berlin (J. Rappich),<br />

employing wet chemical as well as electrochemical processing. A schematic<br />

representation of these surfaces is shown in Figure 3. The methyl-terminated surface is<br />

particular in comparison to the other, longer-chain alkyl-terminations in two aspects: (1)<br />

The methyl (-CH3) termination is the only alkyl species the van-der-Waals radius of which<br />

is small enough such that the passivation of every silicon surface atom by a methyl group<br />

is possible. Our measurements showed that already for the next largest alkyl, i.e. ethyl<br />

(C2H5), only a fractional coverage of about 2/3 of a monolayer are achieved. (2) Methylmodified<br />

n-Si(111) surfaces in the presence of water affect a p-conductive surface<br />

channel, which makes them particularly promising for the implementation as passivation<br />

layers in w-FET devices. The mechanism leading to p-type surface channels is not yet<br />

<strong>und</strong>erstood and is a focal point of our studies.<br />

The chemical, electronic, and structural properties of alkylated Si(111) surfaces are<br />

analysed in our “Solid/Liquid Analysis System” (SoLiAS) at the 3 rd generation synchrotron<br />

facility BESSY II in Berlin. SoLiAS is equipped with the analytical methods of highresolution<br />

photoelectron spectroscopy and low energy electron diffraction (LEED). Figure<br />

2 shows the LEED pattern of ethylated Si(111) which proofs an exceptionally high degree<br />

of lateral ordering of the wet chemically processed surfaces. These surfaces are<br />

subjected to further processing steps within the SoLiAS station such as vacuum thin film<br />

deposition, electrodeposition or gas phase adsorption, etc. which allow for an in-situ<br />

- 75 -