Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Transition of crack closure mechanism in Ti-6Al-4V<br />

Arne Kriegsmann and Clemens Müller<br />

During cyclic loading, fatigue crack closure occurs when crack faces are in contact before<br />

minimum load. It is assumed that no crack-tip damage occurs while crack faces are in<br />

contact, so this portion of the load cycle is ineffective for fatigue crack growth. Therefore,<br />

the effective stress intensity range ∆Keff at the crack tip and thereby the crack propagation<br />

rate decreases.<br />

Fatigue crack closure can result from residual plastic deformations remaining in the wake<br />

of an advancing crack, fracture surface roughness or corrosion deposits in the crack wake.<br />

These three closure mechanisms are called plasticity induced closure, roughness induced<br />

closure and oxide induced closure, respectively.<br />

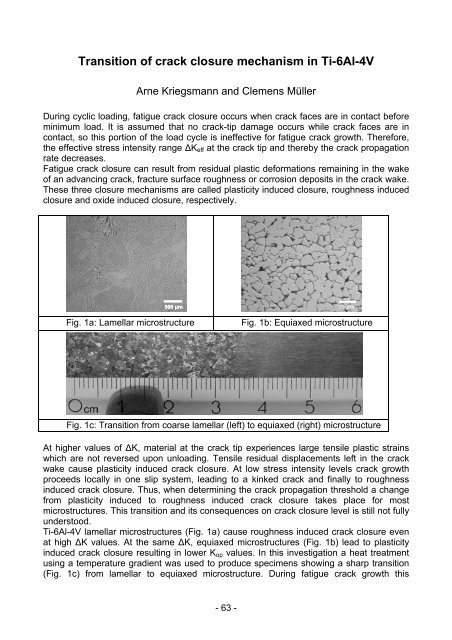

500 µm<br />

25 µm<br />

Fig. 1a: Lamellar microstructure Fig. 1b: Equiaxed microstructure<br />

Fig. 1c: Transition from coarse lamellar (left) to equiaxed (right) microstructure<br />

At higher values of ∆K, material at the crack tip experiences large tensile plastic strains<br />

which are not reversed upon unloading. Tensile residual displacements left in the crack<br />

wake cause plasticity induced crack closure. At low stress intensity levels crack growth<br />

proceeds locally in one slip system, leading to a kinked crack and finally to roughness<br />

induced crack closure. Thus, when determining the crack propagation threshold a change<br />

from plasticity induced to roughness induced crack closure takes place for most<br />

microstructures. This transition and its consequences on crack closure level is still not fully<br />

<strong>und</strong>erstood.<br />

Ti-6Al-4V lamellar microstructures (Fig. 1a) cause roughness induced crack closure even<br />

at high ∆K values. At the same ∆K, equiaxed microstructures (Fig. 1b) lead to plasticity<br />

induced crack closure resulting in lower Kop values. In this investigation a heat treatment<br />

using a temperature gradient was used to produce specimens showing a sharp transition<br />

(Fig. 1c) from lamellar to equiaxed microstructure. During fatigue crack growth this<br />

- 63 -