Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

Electronic Material Properties - und Geowissenschaften ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Gro<strong>und</strong>water treatment technologies<br />

Christoph Schüth<br />

Contamination of gro<strong>und</strong>water with organic contaminants, especially chlorinated<br />

hydrocarbon compo<strong>und</strong>s (CHCs) and petroleum hydrocarbons as constituents of<br />

gasoline, is a wide-spread problem in industrialized countries. The treatment of the<br />

contaminated gro<strong>und</strong>water is in<br />

most cases achieved by<br />

pumping it through an<br />

adsorbent on-site, e.g. granular<br />

activated carbon (GAC). The<br />

efficiency of such a system can<br />

be further increased by air<br />

stripping the contaminants, as<br />

the sorption capacities of these<br />

compo<strong>und</strong>s on GAC are<br />

increased out of the gas-phase,<br />

due to the minimization or<br />

absence of competitive effects<br />

of the gro<strong>und</strong>water itself or<br />

other gro<strong>und</strong>water solutes.<br />

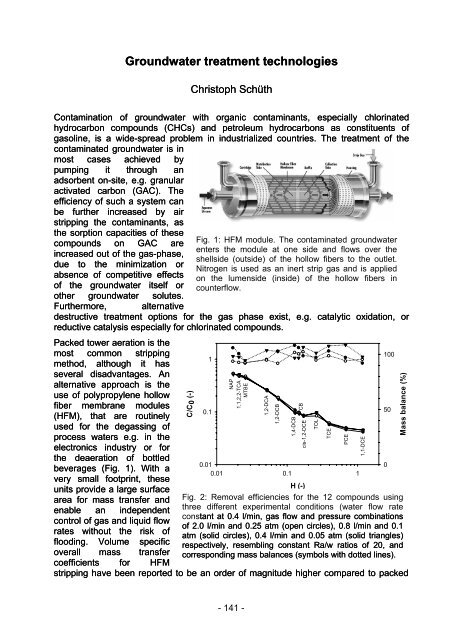

Fig. 1: HFM module. The contaminated gro<strong>und</strong>water<br />

enters the module at one side and flows over the<br />

shellside (outside) of the hollow fibers to the outlet.<br />

Nitrogen is used as an inert strip gas and is applied<br />

on the lumenside (inside) of the hollow fibers in<br />

counterflow.<br />

Furthermore, alternative<br />

destructive treatment options for the gas phase exist, e.g. catalytic oxidation, or<br />

reductive catalysis especially for chlorinated compo<strong>und</strong>s.<br />

Packed tower aeration is the<br />

most common stripping<br />

method, although it has<br />

several disadvantages. An<br />

alternative approach is the<br />

use of polypropylene hollow<br />

1<br />

100<br />

fiber membrane modules<br />

(HFM), that are routinely<br />

used for the degassing of<br />

process waters e.g. in the<br />

electronics industry or for<br />

0.1<br />

50<br />

the deaeration of bottled<br />

beverages (Fig. 1). With a<br />

very small footprint, these<br />

units provide a large surface<br />

area for mass transfer and<br />

enable an independent<br />

control of gas and liquid flow<br />

rates without the risk of<br />

flooding. Volume specific<br />

overall mass transfer<br />

coefficients for HFM<br />

0.01<br />

0<br />

0.01 0.1 1<br />

H (-)<br />

Fig. 2: Removal efficiencies for the 12 compo<strong>und</strong>s using<br />

three<br />

different experimental conditions (water flow rate<br />

constant<br />

tant at 0.4 l/min, gas flow and pressure combinations<br />

of 2.0 l/min and 0.25 atm (open circles), 0.8 l/min and 0.1<br />

atm (solid circles), 0.4 l/min and 0.05 atm (solid triangles)<br />

respectively, resembling constant Ra/w ratios of 20, and<br />

co rresponding mass balances (symbols with dotted lines).<br />

stripping have been reported to be an order of magnitude higher compared to packed<br />

C/C0 (-)<br />

NAP<br />

1,1,2,2-TCA<br />

MTBE<br />

- 141 -<br />

1,2-DCA<br />

1,2-DCB<br />

1,4-DCB<br />

CB<br />

cis-1,2-DCE<br />

TOL<br />

TCE<br />

PCE<br />

1,1-DCE<br />

Mass balance (%)