Stand-Alone Punch machine user manual - Finn-Power International ...

Stand-Alone Punch machine user manual - Finn-Power International ...

Stand-Alone Punch machine user manual - Finn-Power International ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

0-360°- Shows how tooling is on all orientations of the part. Select 0-360° and<br />

delete a tool from the part, this tool will be removed from all. Select any other<br />

orientation to remove/change tooling for that specific rotation.<br />

4.4.4 Sorting<br />

Each part programmed within NC Express requires sorting to be applied. Within a<br />

<strong>Finn</strong>-<strong>Power</strong> <strong>Stand</strong>alone <strong>machine</strong> there are up to four options to sort parts:<br />

Load/Unload Robot (LUR), Microjoints (tabs), Manual, or through a Trap Door.<br />

Not all <strong>Finn</strong>-<strong>Power</strong> <strong>Stand</strong>alone <strong>machine</strong>s will have an LUR attached, but all will<br />

have the ability to utilize Microjoints, Manual, or Trap Door sorting.<br />

When sorting is applied to a part, whether it is an internal or external contour, the<br />

last hit for all contours will have sorting applied. An orientation setting within<br />

Machine Parameters Sorting Device setup controls where the last hit will be. This<br />

setting tells NC Express to apply the selected sorting at a certain rotation<br />

(orientation- Ex. 90°) each time Autotool is ran. The last hit will be displayed on a<br />

part by displaying a yellow arrow on the tool that has last hit applied.<br />

When using Autotool to apply sorting the Unloading – Sorting Device selected will<br />

be applied to the part external and internal (if needed) contour. Part dimensions are<br />

taken into consideration when displaying all available sorting devices. Trap door<br />

for most <strong>Stand</strong>alone <strong>machine</strong>s will only allow small parts to be dropped down them,<br />

which means (if no LUR) the majority of parts programmed for a <strong>Stand</strong>alone<br />

<strong>machine</strong> will utilize either Manual or Microjoints.<br />

4.4.4.1 Automatic Robot Placement<br />

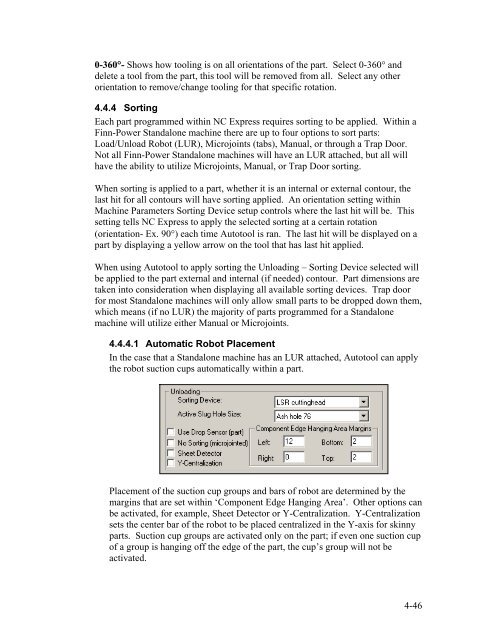

In the case that a <strong>Stand</strong>alone <strong>machine</strong> has an LUR attached, Autotool can apply<br />

the robot suction cups automatically within a part.<br />

Placement of the suction cup groups and bars of robot are determined by the<br />

margins that are set within ‘Component Edge Hanging Area’. Other options can<br />

be activated, for example, Sheet Detector or Y-Centralization. Y-Centralization<br />

sets the center bar of the robot to be placed centralized in the Y-axis for skinny<br />

parts. Suction cup groups are activated only on the part; if even one suction cup<br />

of a group is hanging off the edge of the part, the cup’s group will not be<br />

activated.<br />

4-46