DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

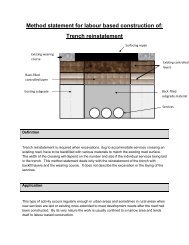

Adequate layer bonding critical:<br />

Bond and tack coats to improve<br />

total structural integrity<br />

Kobus Louw<br />

Research and Development Manager<br />

Colas SA (Pty) Ltd<br />

Worldwide, the design<br />

and construction of<br />

long lasting asphalt<br />

pavements is becoming<br />

increasingly important as<br />

greater demands are placed on<br />

the performance of these<br />

asphalt layers.<br />

Adequate bonding between<br />

asphalt layers is critical if the<br />

completed structure is to behave<br />

as a single structural unit and<br />

provide adequate strength. If the<br />

layers are not properly bonded<br />

together, they will behave as<br />

independent thin layers.<br />

Generally, such individual layers<br />

are not designed to accommodate<br />

the stresses imposed by current<br />

traffic patterns. Damage due to<br />

fatigue and deformation proceeds<br />

at a faster rate when a proper<br />

bond has not been created,<br />

resulting in rapid deterioration of<br />

the pavement structure.<br />

Inadequate bonding can result in<br />

delamination, cracking, potholes<br />

and ingress of water into the<br />

pavement structure.<br />

Over-application of the tack coat<br />

can result in slippage of the<br />

asphalt layers due to the<br />

lubricating effect of the excess<br />

binder.<br />

Tack coats<br />

Tack coats have traditionally been<br />

used in South Africa for improving<br />

the adhesion of hot mix asphalt<br />

layers to the substrates on which<br />

they are placed. These mixes are<br />

usually placed at a thickness of 15<br />

– 60mm. Anionic stable mix<br />

emulsion diluted with equal<br />

quantities of water is commonly<br />

used for this purpose. The<br />

application rate specified in COLTO<br />

is 0,55 l/m 2 for a 30% binder<br />

content emulsion, leaving a net<br />

residual binder application of<br />

approximately 0,165 l/m 2 . The<br />

method of application is often with<br />

a hand sprayer, and the resulting<br />

spread rate and evenness of<br />

application usually leaves much to<br />

be desired and may be referred to<br />

as “a lick and promise”. Paving<br />

can only commence after the<br />

emulsion has “broken”.<br />

130