DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Bitumen stabilised materials:<br />

In search of sustainable<br />

pavement design solutions<br />

Kim Jenkins<br />

Professor<br />

SANRAL Chair<br />

University of Stellenbosch<br />

Dr Fritz Jooste<br />

Director<br />

Modelling and Analysis<br />

Systems (MAS)<br />

Over the past two<br />

decades many South<br />

African pavement<br />

engineers have become aware<br />

of mounting pressure to<br />

conserve the environment,<br />

coupled with a decreasing<br />

availability of crushed stone<br />

material.<br />

These two issues have prompted a<br />

radical<br />

re-assessment<br />

of the manner<br />

in which<br />

pavement<br />

design is being<br />

approached in<br />

South Africa.<br />

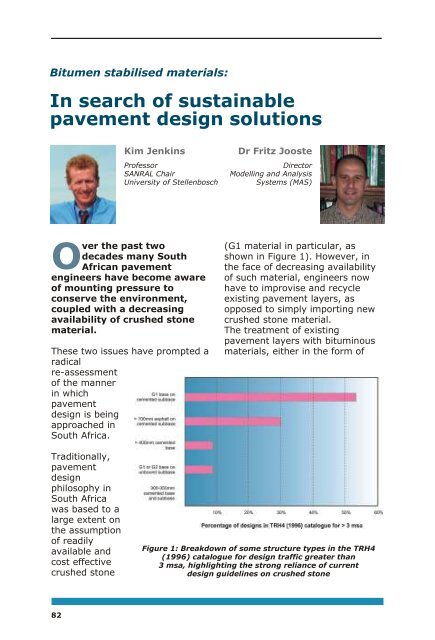

(G1 material in particular, as<br />

shown in Figure 1). However, in<br />

the face of decreasing availability<br />

of such material, engineers now<br />

have to improvise and recycle<br />

existing pavement layers, as<br />

opposed to simply importing new<br />

crushed stone material.<br />

The treatment of existing<br />

pavement layers with bituminous<br />

materials, either in the form of<br />

Traditionally,<br />

pavement<br />

design<br />

philosophy in<br />

South Africa<br />

was based to a<br />

large extent on<br />

the assumption<br />

of readily<br />

available and<br />

cost effective<br />

crushed stone<br />

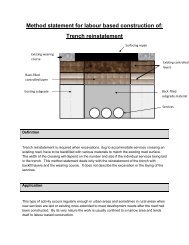

Figure 1: Breakdown of some structure types in the TRH4<br />

(1996) catalogue for design traffic greater than<br />

3 msa, highlighting the strong reliance of current<br />

design guidelines on crushed stone<br />

82