DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

peak value of 1,2 J/cm 2 . Typical<br />

results appear in Figure 1.<br />

(ii) Julian Wise and Derick<br />

Pretorius conducted tests in 2003<br />

to determine the shear force<br />

required to dislodge a UTFC layer<br />

from a continuously graded SABS<br />

mix.<br />

In summary the following<br />

procedures were conducted:<br />

• Base briquettes were<br />

prepared in Marshall moulds<br />

according to the SABS mix<br />

specification, and compacted<br />

to 88% and 90% respectively<br />

of Rice, and allowed to cool;<br />

• Bond coat applied on top of<br />

SABS mix, followed by UTFC,<br />

and compacted with 100<br />

blows on one side only;<br />

• Composite briquette pushed<br />

partly out of mould to expose<br />

joint;<br />

• Load applied with a CBR<br />

press to determine shear<br />

force.<br />

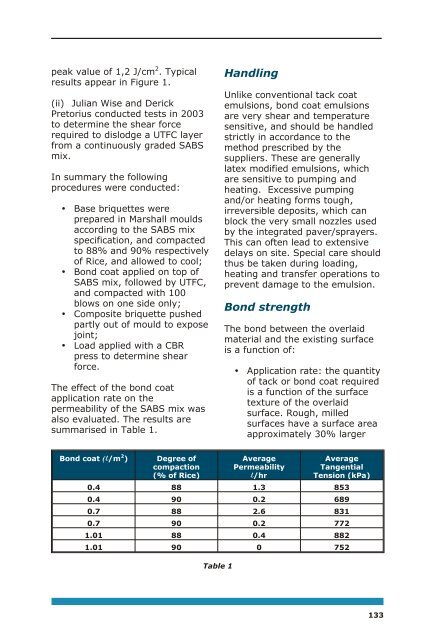

The effect of the bond coat<br />

application rate on the<br />

permeability of the SABS mix was<br />

also evaluated. The results are<br />

summarised in Table 1.<br />

Handling<br />

Unlike conventional tack coat<br />

emulsions, bond coat emulsions<br />

are very shear and temperature<br />

sensitive, and should be handled<br />

strictly in accordance to the<br />

method prescribed by the<br />

suppliers. These are generally<br />

latex modified emulsions, which<br />

are sensitive to pumping and<br />

heating. Excessive pumping<br />

and/or heating forms tough,<br />

irreversible deposits, which can<br />

block the very small nozzles used<br />

by the integrated paver/sprayers.<br />

This can often lead to extensive<br />

delays on site. Special care should<br />

thus be taken during loading,<br />

heating and transfer operations to<br />

prevent damage to the emulsion.<br />

Bond strength<br />

The bond between the overlaid<br />

material and the existing surface<br />

is a function of:<br />

• Application rate: the quantity<br />

of tack or bond coat required<br />

is a function of the surface<br />

texture of the overlaid<br />

surface. Rough, milled<br />

surfaces have a surface area<br />

approximately 30% larger<br />

Bond coat (l/m 2 )<br />

Degree of<br />

compaction<br />

(% of Rice)<br />

Average<br />

Permeability<br />

l/hr<br />

Average<br />

Tangential<br />

Tension (kPa)<br />

0.4 88 1.3 853<br />

0.4 90 0.2 689<br />

0.7 88 2.6 831<br />

0.7 90 0.2 772<br />

1.01 88 0.4 882<br />

1.01 90 0 752<br />

Table 1<br />

133