DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

air permeability recommended in<br />

TRH8 (1987) which is less than<br />

1,0 x 10 6 cm 3 /second.<br />

The required Voids Filled with<br />

Binder (VFB) should lie between<br />

65% and 75% (Superpave 2001).<br />

The values of VFB obtained in the<br />

mix design are slightly on the high<br />

side, due to the high VMA, which,<br />

along with the voids in the mix,<br />

determine the VFB.<br />

Additional testing<br />

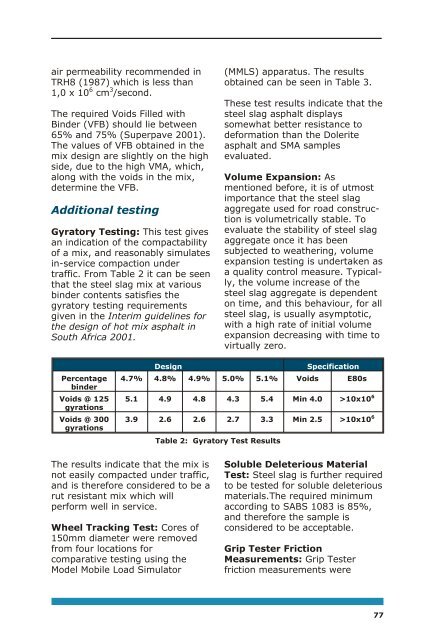

Gyratory Testing: This test gives<br />

an indication of the compactability<br />

of a mix, and reasonably simulates<br />

in-service compaction under<br />

traffic. From Table 2 it can be seen<br />

that the steel slag mix at various<br />

binder contents satisfies the<br />

gyratory testing requirements<br />

given in the Interim guidelines for<br />

the design of hot mix asphalt in<br />

South Africa 2001.<br />

(MMLS) apparatus. The results<br />

obtained can be seen in Table 3.<br />

These test results indicate that the<br />

steel slag asphalt displays<br />

somewhat better resistance to<br />

deformation than the Dolerite<br />

asphalt and SMA samples<br />

evaluated.<br />

Volume Expansion: As<br />

mentioned before, it is of utmost<br />

importance that the steel slag<br />

aggregate used for road construction<br />

is volumetrically stable. To<br />

evaluate the stability of steel slag<br />

aggregate once it has been<br />

subjected to weathering, volume<br />

expansion testing is undertaken as<br />

a quality control measure. Typically,<br />

the volume increase of the<br />

steel slag aggregate is dependent<br />

on time, and this behaviour, for all<br />

steel slag, is usually asymptotic,<br />

with a high rate of initial volume<br />

expansion decreasing with time to<br />

virtually zero.<br />

Percentage<br />

binder<br />

Voids @ 125<br />

gyrations<br />

Voids @ 300<br />

gyrations<br />

Design<br />

Specification<br />

4.7% 4.8% 4.9% 5.0% 5.1% Voids E80s<br />

5.1 4.9 4.8 4.3 5.4 Min 4.0 >10x10 6<br />

3.9 2.6 2.6 2.7 3.3 Min 2.5 >10x10 6<br />

Table 2: Gyratory Test Results<br />

The results indicate that the mix is<br />

not easily compacted under traffic,<br />

and is therefore considered to be a<br />

rut resistant mix which will<br />

perform well in service.<br />

Wheel Tracking Test: Cores of<br />

150mm diameter were removed<br />

from four locations for<br />

comparative testing using the<br />

Model Mobile Load Simulator<br />

Soluble Deleterious Material<br />

Test: Steel slag is further required<br />

to be tested for soluble deleterious<br />

materials.The required minimum<br />

according to SABS 1083 is 85%,<br />

and therefore the sample is<br />

considered to be acceptable.<br />

Grip Tester Friction<br />

Measurements: Grip Tester<br />

friction measurements were<br />

77