DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

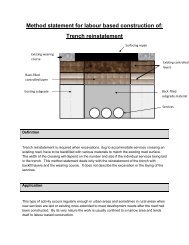

oad construction. As mentioned<br />

previously, the weathering of the<br />

aggregate is of utmost importance<br />

to the stability of the aggregate,<br />

and is considered to be one of the<br />

most important aspects of raw<br />

materials handling.<br />

Steel slag asphalt mixes<br />

The objective of investigating steel<br />

slag asphalt mixtures was to<br />

produce a rut resistant asphalt for<br />

application where traffic loading is<br />

high, vehicle speeds low, and<br />

environmental conditions varying.<br />

Trial steel slag asphalt mixes were<br />

prepared for use during the N3<br />

Toll Concession (N3TC) routine<br />

maintenance contract between<br />

Heidelberg and Cedara.<br />

A mix design was completed using<br />

the steel slag as an aggregate,<br />

along with a filler to satisfy the<br />

-0,075mm grading limits. The<br />

grading specification used for the<br />

mix design was according to TRH8<br />

(Coarse). A 4% SBS modified<br />

binder was used to enhance the<br />

natural properties of the bitumen<br />

by making the binder more elastic<br />

at higher temperatures, which in<br />

turn enables the binder to<br />

withstand repeated traffic loading<br />

and reduces rutting potential.<br />

Results<br />

For the mix adopted, the<br />

specification required a stability<br />

within the range 8,0 kN – 18,0 kN.<br />

Test results indicated a stability in<br />

the region of 15,0 kN. This can in<br />

part be attributed to both the use<br />

of steel slag as an aggregate, and<br />

to the polymer modified binder.<br />

The higher stability indicated that<br />

the mix was ideally suited to the<br />

requirements of a deformation<br />

resistant asphalt surfacing. The<br />

maximum flow recorded at the<br />

various binder contents tested was<br />

4mm compared to the recommended<br />

range of 2 – 6mm.<br />

The Indirect Tensile Strength (ITS)<br />

of the mix is a measure of the<br />

stiffness of an asphalt mix i.e. how<br />

well it distributes loading to<br />

underlying layers. In the Interim<br />

guidelines for the design of hot<br />

mix asphalt in South Africa 2001,<br />

the minimum recommended<br />

stiffness for a surfacing mix is<br />

1000 kPa. The stiffness of the<br />

steel slag mix design reported,<br />

1280 kPa, is significantly higher<br />

than this minimum requirement.<br />

The above document also<br />

recommends a minimum Voids in<br />

Mineral Aggregate (VMA) of<br />

15,0%. Low VMA asphalt mixes<br />

tend to be sensitive to changes in<br />

binder content and create tender<br />

mixes that may be more inclined<br />

to rutting and bleeding. The<br />

minimum VMA recorded for the<br />

binder contents tested – 16,3% –<br />

exceeds the minimum requirement<br />

and is suited to a rut resistant and<br />

durable asphalt surfacing.<br />

To optimise void content to<br />

counter air and water permeability<br />

on the one hand, and fattiness and<br />

bleeding on the other, a target<br />

Voids in Mix (VIM) of 4% was<br />

adopted, as suggested by<br />

Superpave 2001. The reported<br />

results for the steel slag mix<br />

design, was very close to the<br />

optimum voids content of 4%, and<br />

the mix met the requirement for<br />

76