DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

DIGEST 2006 - Sabita

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ecommendations (R69/97 for<br />

bituminous mix design) involves<br />

an analytical study prior to<br />

verification by mechanical testing.<br />

This analytical study is supported<br />

by a software package called<br />

PRADO (Programmes for Asphalt<br />

Mix Design and Optimisation).<br />

This method aims to achieve the<br />

best possible compromise between<br />

various (and sometimes<br />

conflicting) requirements such as<br />

dealing with both resistance to<br />

fatigue and rutting of the mix. In<br />

Volumetric and mastic<br />

evaluation of dolerite and<br />

quartzite mixes:<br />

Theoretical volumetric calculations<br />

using PRADO software were done<br />

for both the designs incorporating<br />

both dolerite and quartzite. The<br />

results of the volumetric analysis<br />

(estimating VIM, VMA and the<br />

filler/binder ratio - by both mass<br />

and volume – and the stiffening<br />

effect of the mastic) over a range<br />

of binder contents were calculated<br />

as follows:<br />

Dolerite<br />

Quartzite<br />

Binder content (%)<br />

4<br />

4.5<br />

5<br />

5.5<br />

4<br />

4.5<br />

5<br />

5.5<br />

Estimated VIM (%)<br />

PRADO<br />

7.7<br />

6.5<br />

5.3<br />

4.1<br />

6.2<br />

5.1<br />

4.0<br />

2.9<br />

VIM (%) laboratory<br />

7.7<br />

5.4<br />

4.0<br />

3.6<br />

6.8<br />

4.9<br />

3.2<br />

1.5<br />

Estimated VMA (%)<br />

PRADO<br />

VMA (%) laboratory<br />

Filler/binder ratio (by<br />

mass)<br />

Filler/binder ratio (by<br />

volume)<br />

T R&B increase (mastic vs<br />

binder)<br />

17.1<br />

17.5<br />

1.4<br />

0.49<br />

11.9<br />

17.1<br />

16.7<br />

1.24<br />

0.44<br />

10<br />

17.1<br />

16.5<br />

1.12<br />

0.39<br />

8.7<br />

17.1<br />

17.4<br />

1.02<br />

0.36<br />

7.7<br />

15.3<br />

15.7<br />

15.9<br />

0.60<br />

21.7<br />

15.3<br />

15.1<br />

1.41<br />

0.53<br />

17.4<br />

15.3<br />

14.7<br />

12.7<br />

0.48<br />

14.6<br />

15.3<br />

14.4<br />

1.16<br />

0.43<br />

12.5<br />

Table 2: PRADO Mix Design Estimates Versus Actual Volumes<br />

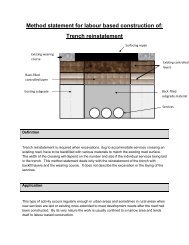

this approach, the stability of the<br />

mix can be ensured by making use<br />

of intergranular friction while<br />

avoiding overfilling the mineral<br />

skeleton with mastic (i.e. with<br />

filler and binder). This mastic<br />

should only fill part of the voids in<br />

the mineral aggregate and should<br />

also have the right consistency<br />

(i.e. the correct proportion of filler<br />

and binder).<br />

Dolerite aggregate evaluation<br />

results<br />

In general the estimated VIM and<br />

VMA values as predicted by<br />

PRADO are slightly higher than the<br />

values obtained in the laboratory.<br />

From Table 2 it can be seen that<br />

the increase in the Ring & Ball<br />

temperature of the mastic<br />

105