Mr. Erik Milito - The House Committee on Natural Resources ...

Mr. Erik Milito - The House Committee on Natural Resources ...

Mr. Erik Milito - The House Committee on Natural Resources ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ISOLATING POTENTIAL FLOW ZONES DURING WELL CONSTRUCTION 51<br />

This substantially decreases the annular column hydrostatic pressure across potential flow z<strong>on</strong>es within the<br />

cemented annulus. This decreased hydrostatic pressure allows formati<strong>on</strong> fluids to influx into the wellbore which starts<br />

annular flows that can lead to LWC incidents.<br />

Another way for lost circulati<strong>on</strong> during cementing operati<strong>on</strong>s to lead to LWC incidents is when the actual TOC does<br />

not reach the planned depth to cover potential flow z<strong>on</strong>es and, instead, places drilling fluid across these formati<strong>on</strong>s. If<br />

the drilling fluid hydrostatic pressure is below the formati<strong>on</strong>’s pore pressure, annular flows may start immediately. If<br />

the drilling fluid hydrostatic pressure is above the formati<strong>on</strong>’s pore pressure, an annular flow may not start until drilling<br />

fluid gellati<strong>on</strong> (also called SGS development), solids settling, etc. decreases the hydrostatic pressure enough to<br />

create an underbalanced pressure c<strong>on</strong>diti<strong>on</strong>. See A.14, 4) for more informati<strong>on</strong> <strong>on</strong> this phenomen<strong>on</strong>.<br />

Cement channeling may cause total or partial lost circulati<strong>on</strong> during primary cementing by initially raising the cement<br />

column to l<strong>on</strong>ger than planned heights (shallower depths) which results in pressures greater than fracture initiati<strong>on</strong>/<br />

propagati<strong>on</strong> pressures. Relevant formati<strong>on</strong>s exposed to these pressures then “breakdown” or fracture and start taking<br />

volumes of the cement slurry out of the annulus. When this occurs, the annular fluid level drops (called “fallback” or the<br />

annular fluid flow rate out of the well decreases to less than the rate pumped into the well. In either case, the risk of an<br />

LWC incident increases when these losses result in underbalanced pressure c<strong>on</strong>diti<strong>on</strong>s across potential flow z<strong>on</strong>es.<br />

Applying adequate measures to prevent cement channeling and associated losses are described herein including<br />

methods to optimize drilling fluid and cuttings removal/displacement by operati<strong>on</strong>al procedures and cementing job<br />

designs such as measuring drilling fluid c<strong>on</strong>diti<strong>on</strong>ing and hole cleaning performance with fluid calipers (see 5.2), pipe<br />

movement, installing centralizers, and pumping relevant cement flushes and spacers at engineered rates.<br />

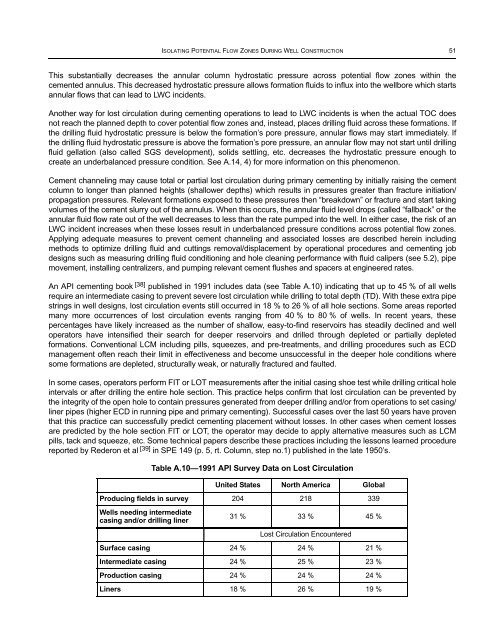

An API cementing book [38] published in 1991 includes data (see Table A.10) indicating that up to 45 % of all wells<br />

require an intermediate casing to prevent severe lost circulati<strong>on</strong> while drilling to total depth (TD). With these extra pipe<br />

strings in well designs, lost circulati<strong>on</strong> events still occurred in 18 % to 26 % of all hole secti<strong>on</strong>s. Some areas reported<br />

many more occurrences of lost circulati<strong>on</strong> events ranging from 40 % to 80 % of wells. In recent years, these<br />

percentages have likely increased as the number of shallow, easy-to-find reservoirs has steadily declined and well<br />

operators have intensified their search for deeper reservoirs and drilled through depleted or partially depleted<br />

formati<strong>on</strong>s. C<strong>on</strong>venti<strong>on</strong>al LCM including pills, squeezes, and pre-treatments, and drilling procedures such as ECD<br />

management often reach their limit in effectiveness and become unsuccessful in the deeper hole c<strong>on</strong>diti<strong>on</strong>s where<br />

some formati<strong>on</strong>s are depleted, structurally weak, or naturally fractured and faulted.<br />

In some cases, operators perform FIT or LOT measurements after the initial casing shoe test while drilling critical hole<br />

intervals or after drilling the entire hole secti<strong>on</strong>. This practice helps c<strong>on</strong>firm that lost circulati<strong>on</strong> can be prevented by<br />

the integrity of the open hole to c<strong>on</strong>tain pressures generated from deeper drilling and/or from operati<strong>on</strong>s to set casing/<br />

liner pipes (higher ECD in running pipe and primary cementing). Successful cases over the last 50 years have proven<br />

that this practice can successfully predict cementing placement without losses. In other cases when cement losses<br />

are predicted by the hole secti<strong>on</strong> FIT or LOT, the operator may decide to apply alternative measures such as LCM<br />

pills, tack and squeeze, etc. Some technical papers describe these practices including the less<strong>on</strong>s learned procedure<br />

reported by Reder<strong>on</strong> et al [39] in SPE 149 (p. 5, rt. Column, step no.1) published in the late 1950’s.<br />

Table A.10—1991 API Survey Data <strong>on</strong> Lost Circulati<strong>on</strong><br />

United States North America Global<br />

Producing fields in survey 204 218 339<br />

Wells needing intermediate<br />

casing and/or drilling liner<br />

31 % 33 % 45 %<br />

Lost Circulati<strong>on</strong> Encountered<br />

Surface casing 24 % 24 % 21 %<br />

Intermediate casing 24 % 25 % 23 %<br />

Producti<strong>on</strong> casing 24 % 24 % 24 %<br />

Liners 18 % 26 % 19 %